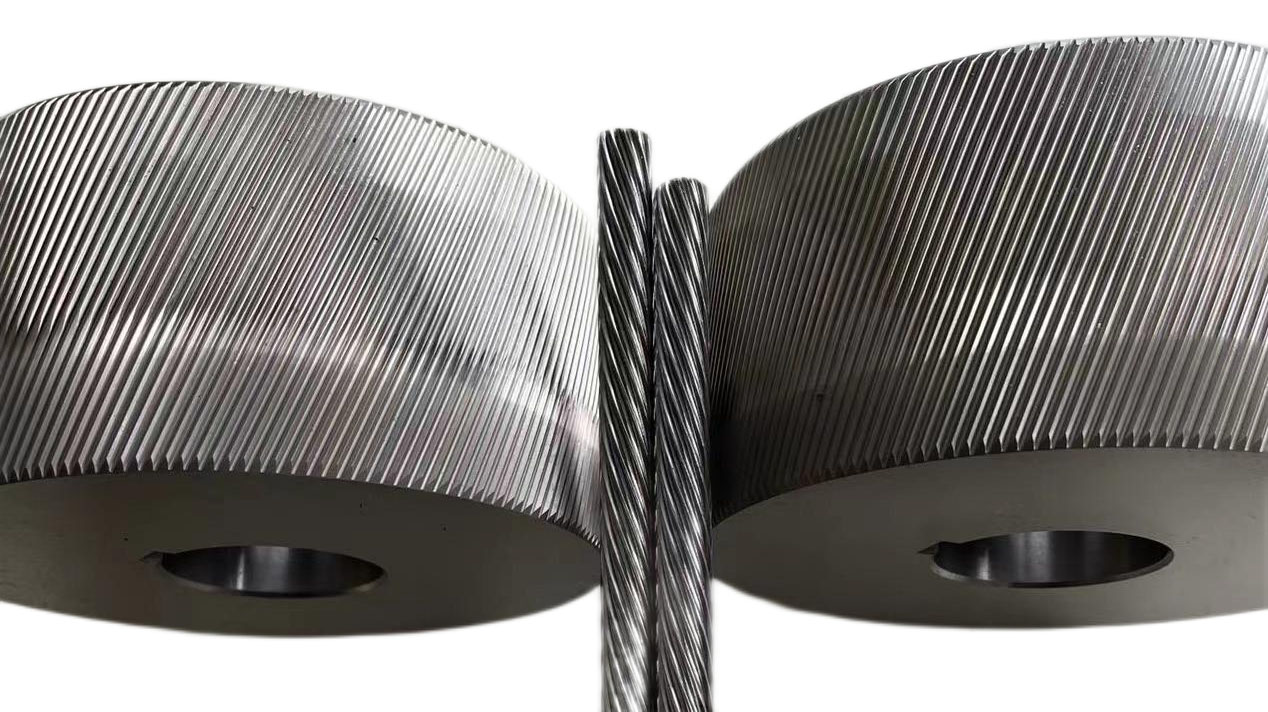

Thread roller

You can rest assured to buy MJ Aerospace Thread die from our factory and we will offer you the best after-sale service and timely delivery. With competitive prices and reliable delivery services, we are expecting become your long-term partner in China.

1.The thread or rob processing of airline parts

2. High-precision grinding and processing method

3. The materials we used were DC53, D2, SKD 11, and Cr12Mov

4. The hardness is 58-61 HRC after heat treatment

5. Outer diameter, inner diameter, width, and keyway size can be customized

6. Heavy grinding is optional

MJ Aerospace Thread are designed for specific customer applications, ranging from standard thread teeth to high precision ball screw, screw and spline applications. Thread rolling die is used for feed and through feeding process. Different processing methods are also different.

There are two kinds of processing methods of rolling wheel, one is grinding, the other is rolling. The surface of the die is carburized, and the hardness of the finished rolling silk die is generally about 57-61 HRC. The hardness of the workpiece is generally below 35 HRC. If it is higher than 35 HRC, the life of ordinary thread roller will be shortened, so better material roll molds, such as DC53, HSS, etc.

we will offer you the best after-sale service and timely delivery. The roller required for thread rolling needs excellent tool steel as material blank. The famous tool steel used by our company is DC53 as material. After high temperature treatment by Japanese TECHNO vacuum oil quenching furnace of our company's heat treatment department, the roller has high hardness and wear resistance. After the heat treatment is completed, the thread is ground by the Swiss REISHAUER thread of the grinding department. After the fine grinding thread is formed, it is sent back to the heat treatment department to eliminate the internal stress of the grinding. After the quality inspection is completed, it is sent to the customer for use. The use of the company's tooth rolling machine and roller must be able to produce a large number of high precision, high tension thread workpiece. In addition to the production of our own type of tooth roller roller roller, other types of roller can be supplied in large quantities, welcome to order.

Inquiry

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: +86-13932160342

MESSAGES

Qucik Link

Contact

Phone: +86-13932160342,+86-15100123091

Address: No.98 Huanghe Road, High-tech Zone, Shijiazhuang City, China