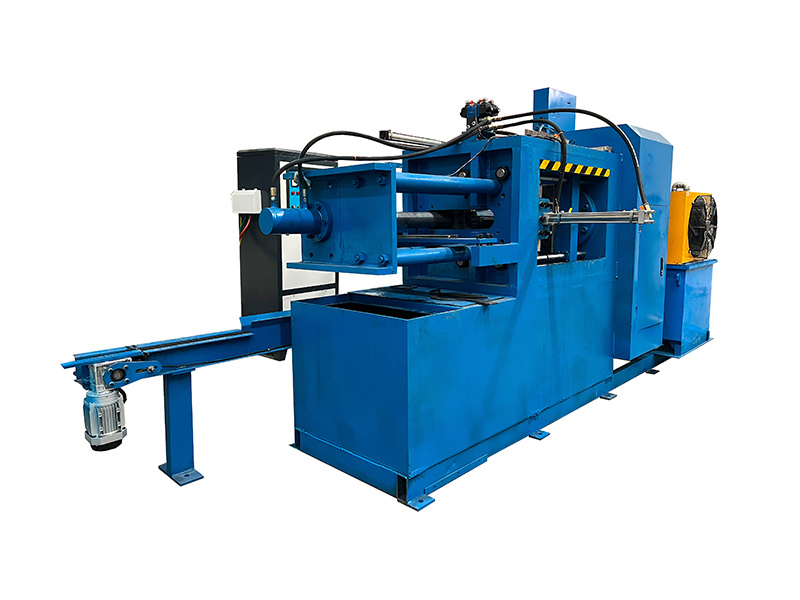

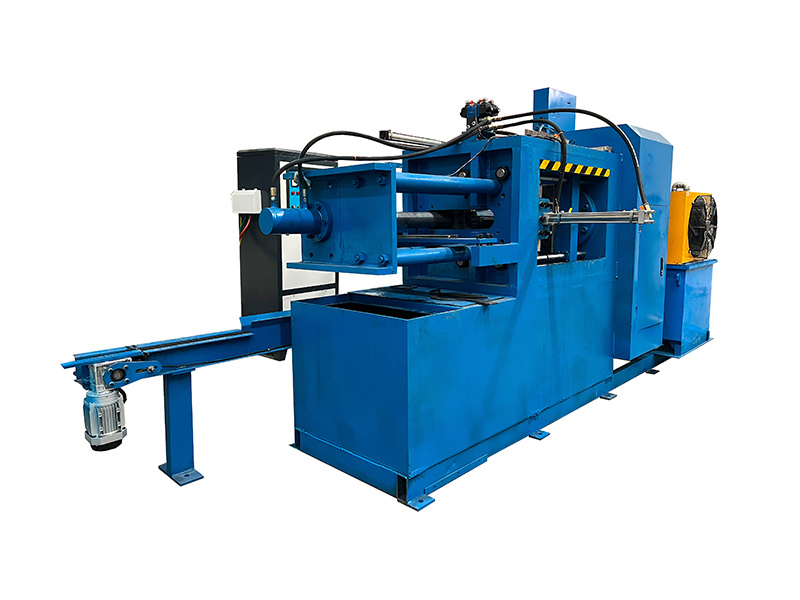

Bolt Hot Forging Machine

Bolt Hot Forging Machine is a highly efficient equipment specially used for bolt manufacturing.

1. Working Principle

Bolt Hot Forging Machine mainly uses hot forging process. When working, the raw material is first heated to the appropriate forging temperature. For bolt production, suitable metal materials (such as carbon steel, etc.) become easier to shape and deform after being heated. Then, the metal is forged according to the pre-set die shape through the powerful pressure device of the machine. This forging method enables various parts of the bolt (such as head, screw, etc.) to be formed in one or more forging processes, ensuring the integrity and strength of the overall structure of the bolt.

2. Performance characteristics

High-strength forging

The hot forging process optimizes the grain structure inside the metal and makes the streamline distribution of the material more reasonable. This makes the produced bolts have higher strength and better toughness, can withstand greater tension, pressure and shear force, and provide reliable tightening in various mechanical connections.

High-precision forming

Bolt Hot Forging Machine is equipped with a high-precision die system. These dies are precisely processed to accurately shape the shape and size of the bolt. Whether it is a common bolt or a bolt of special specifications, it can ensure that the dimensional accuracy of the head shape, screw diameter and thread is within a very small tolerance range to meet different industrial needs.

Efficient production

It has high production efficiency. The hot forging machine can realize continuous forging operations and produce bolts in large quantities in a short time. Moreover, compared with the traditional bolt processing method, the hot forging process reduces multiple processing steps, saving time and cost.

High material utilization rate

Since hot forging is carried out in the plastic state of the material, it can make full use of the raw materials and reduce the generation of waste. This not only reduces the production cost, but also meets the requirements of sustainable development of modern industry.

3. Application field

Bolt Hot Forging Machine is widely used in many industries such as automobile manufacturing, mechanical equipment manufacturing, and construction engineering. In automobile manufacturing, it provides high-strength bolts for components such as engines and chassis; in construction engineering, it is used to connect various steel structure components, etc.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

AISEN machinery inverted wire drawing machine