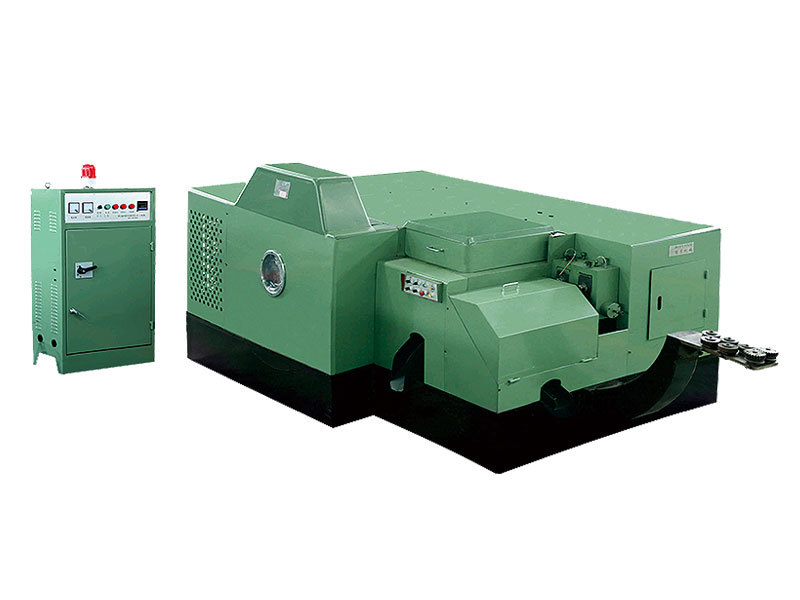

Nut Hot Forging Machine

The Nut Hot Forging Machine is an advanced machine specifically designed for nut production.

1. Advantages of Hot Forging

The hot forging process is the core feature of the Nut Hot Forging Machine. During the hot forging process, the metal material is exposed to high temperatures, significantly enhancing its plasticity. This makes the nut easier to form during forging, effectively reducing stress during the forging process and improving the internal quality of the nut. Compared to cold forging, hot forged nuts exhibit improved mechanical properties, such as increased strength and toughness, ensuring reliability in practical applications.

2. Efficient Production Capacity

The Nut Hot Forging Machine boasts efficient production capacity. Equipped with a powerful power system, it rapidly heats, forges, and forms the raw material. The entire production process, from raw material to finished nut, is seamlessly completed, significantly shortening production cycle time. Whether it's large-scale nut production or small-batch custom production, the Nut Hot Forging Machine can meet production needs with high speed, effectively improving production efficiency.

3. Precision Forming

The machine boasts extremely high precision in forming. Its precisely designed molds ensure strict control of the nut's size and shape. Whether it's the outer or inner diameter of the nut, or the shape and spacing of the thread threads, they are all precisely formed to standard requirements. This ensures the nuts fit perfectly with the matching bolts, avoiding assembly problems caused by nut size deviations.

4. Wide Applicability

The Nut Hot Forging Machine is suitable for a variety of metal materials, including carbon steel, alloy steel, and other common nut-making materials. Furthermore, it can be adjusted to suit different nut specifications, producing a variety of nut types, such as hexagonal and square nuts. Nut Hot Forging Machines are indispensable equipment in numerous industries that utilize large quantities of nuts, such as construction, machinery manufacturing, and automotive manufacturing.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

AISEN machinery inverted wire drawing machine