Maximizing Efficiency with Double Head Chamfering Machines: A Comprehensive Guide

Summary:

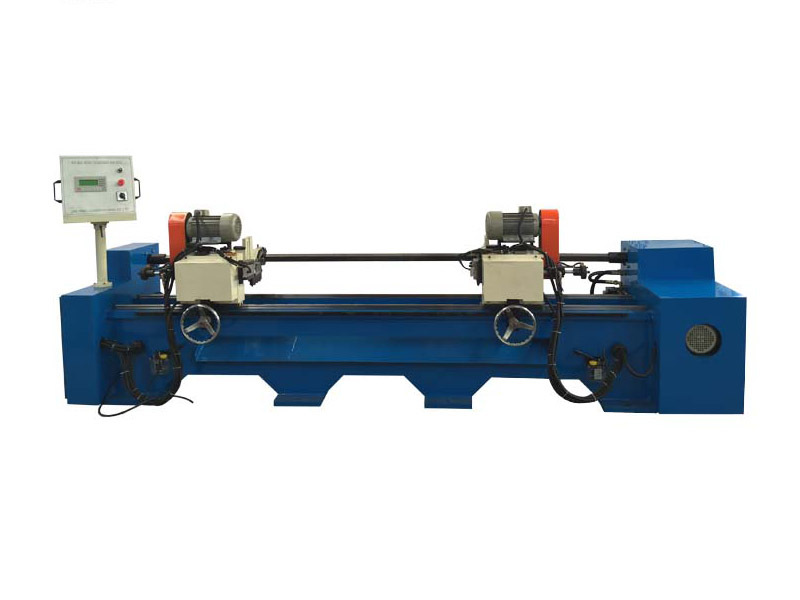

Double head chamfering machines are essential tools in the manufacturing and machining industries, particularly for those working with metal and other rigid materials. These machines are specifically designed to create precise bevels on the edges of workpieces, which is crucial for various applications, including assembly, welding, and aesthetic finishing.

One of the primary advantages of using a

Double head chamfering machines are essential tools in the manufacturing and machining industries, particularly for those working with metal and other rigid materials. These machines are specifically designed to create precise bevels on the edges of workpieces, which is crucial for various applications, including assembly, welding, and aesthetic finishing.

One of the primary advantages of using a double head chamfering machine is the increased efficiency it offers. Unlike single head machines that can only work on one edge at a time, double head machines can process two edges simultaneously. This capability significantly reduces the time required for chamfering tasks, making them ideal for high-volume production scenarios. Manufacturers benefit from increased output without compromising the quality of the finished product.

The design of double head chamfering machines usually incorporates advanced features that enhance precision and control. Many models feature adjustable angles, allowing operators to create various bevel sizes and shapes. This flexibility is particularly beneficial for projects that require specific chamfer dimensions to meet strict tolerances. Additionally, the use of carbide or high-speed steel cutting tools in these machines ensures durability and sharpness, resulting in clean, smooth edges.

In terms of safety, double head chamfering machines are designed with operator protection in mind. Many machines come equipped with safety guards and emergency stop features to minimize the risk of accidents. Proper training in machine operation and adherence to safety protocols are essential for maintaining a secure working environment.

Moreover, the versatility of double head chamfering machines extends beyond conventional machining tasks. They can be employed in various industries, including automotive, aerospace, and construction, where precise edge preparation is crucial. This adaptability makes them an invaluable asset for manufacturers looking to streamline their processes and elevate product quality.

Maintenance of double head chamfering machines is crucial for ensuring their longevity and performance. Regular inspections, cleaning, and timely replacement of worn components can prevent costly downtimes and extend the lifespan of the equipment. Operators should also familiarize themselves with the machine's user manual to understand the recommended maintenance schedules and practices.

In conclusion, double head chamfering machines represent a critical innovation in the field of manufacturing and machining. Their ability to improve efficiency, enhance precision, and ensure safety makes them a preferred choice for businesses aiming to optimize their production processes. By investing in these machines and understanding their functionalities, manufacturers can stay competitive in a rapidly evolving industry landscape.

One of the primary advantages of using a double head chamfering machine is the increased efficiency it offers. Unlike single head machines that can only work on one edge at a time, double head machines can process two edges simultaneously. This capability significantly reduces the time required for chamfering tasks, making them ideal for high-volume production scenarios. Manufacturers benefit from increased output without compromising the quality of the finished product.

The design of double head chamfering machines usually incorporates advanced features that enhance precision and control. Many models feature adjustable angles, allowing operators to create various bevel sizes and shapes. This flexibility is particularly beneficial for projects that require specific chamfer dimensions to meet strict tolerances. Additionally, the use of carbide or high-speed steel cutting tools in these machines ensures durability and sharpness, resulting in clean, smooth edges.

In terms of safety, double head chamfering machines are designed with operator protection in mind. Many machines come equipped with safety guards and emergency stop features to minimize the risk of accidents. Proper training in machine operation and adherence to safety protocols are essential for maintaining a secure working environment.

Moreover, the versatility of double head chamfering machines extends beyond conventional machining tasks. They can be employed in various industries, including automotive, aerospace, and construction, where precise edge preparation is crucial. This adaptability makes them an invaluable asset for manufacturers looking to streamline their processes and elevate product quality.

Maintenance of double head chamfering machines is crucial for ensuring their longevity and performance. Regular inspections, cleaning, and timely replacement of worn components can prevent costly downtimes and extend the lifespan of the equipment. Operators should also familiarize themselves with the machine's user manual to understand the recommended maintenance schedules and practices.

In conclusion, double head chamfering machines represent a critical innovation in the field of manufacturing and machining. Their ability to improve efficiency, enhance precision, and ensure safety makes them a preferred choice for businesses aiming to optimize their production processes. By investing in these machines and understanding their functionalities, manufacturers can stay competitive in a rapidly evolving industry landscape.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us