How an Automatic U Bolt Bending Machine Revolutionizes Metal Fabrication

Summary:

How an Automatic U Bolt Bending Machine Revolutionizes Metal Fabrication

Table of Contents

1. Introduction to U Bolt Bending Machines

2. Understanding the Need for Automation in Metal Fabrication

3. Benefits of Automatic U Bolt Bending Machines

4. How U Bolt Bending Machines Work

5. Key Features of Modern U Bolt Bending Machines

6. Applications of U Bolt Bending Machines i

How an Automatic U Bolt Bending Machine Revolutionizes Metal Fabrication

Table of Contents

- 1. Introduction to U Bolt Bending Machines

- 2. Understanding the Need for Automation in Metal Fabrication

- 3. Benefits of Automatic U Bolt Bending Machines

- 4. How U Bolt Bending Machines Work

- 5. Key Features of Modern U Bolt Bending Machines

- 6. Applications of U Bolt Bending Machines in Various Industries

- 7. Cost Efficiency and Return on Investment

- 8. The Future of Metal Fabrication with U Bolt Bending Machines

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to U Bolt Bending Machines

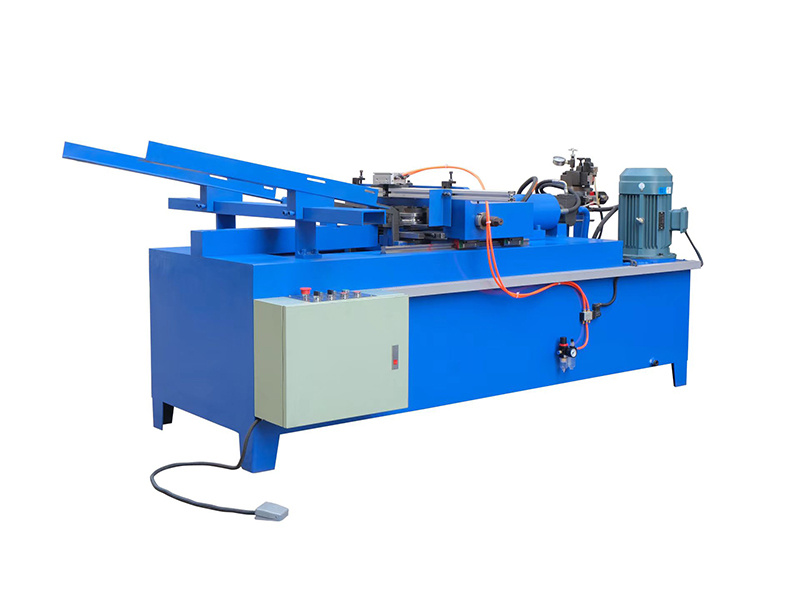

In the landscape of metal fabrication, efficiency and precision are paramount. **Automatic U Bolt Bending Machines** stand as a remarkable innovation, addressing the growing demands for both speed and accuracy in metal shaping processes. U bolts, which are essential components in various industries, require precise bending to ensure proper fit and function. This article delves into how these machines have transformed the metal fabrication industry, making operations smoother and more reliable.

2. Understanding the Need for Automation in Metal Fabrication

The need for **automation in metal fabrication** arises from several factors. Traditional methods often rely on manual labor, which can lead to inconsistencies and errors in production. As industries strive for higher standards, integrating automated solutions becomes imperative.

- **Increased Demand**: With the rise of the construction, automotive, and aerospace sectors, the demand for U bolts has surged, necessitating a more streamlined production process.

- **Labor Challenges**: Skilled labor shortages make it increasingly difficult to maintain high-quality standards solely through manual processes.

- **Precision Requirements**: Modern applications require tighter tolerances and greater accuracy than ever before, which can be challenging to achieve through manual bending.

Automatic U bolt bending machines rise to meet these challenges, offering solutions that enhance productivity while maintaining quality.

3. Benefits of Automatic U Bolt Bending Machines

Investing in **automatic U bolt bending machines** provides multiple advantages:

3.1 Enhanced Efficiency

Automatic machines significantly outperform manual processes, reducing production time and increasing throughput. This efficiency allows manufacturers to meet tighter deadlines without compromising quality.

3.2 Improved Accuracy

The precision engineering of these machines ensures that every U bolt is bent to exact specifications. Consistency in production minimizes the risk of errors, which can lead to costly reworks.

3.3 Reduction in Labor Costs

With automation, manufacturers can reduce their reliance on skilled labor, cutting labor costs while reallocating human resources to more complex tasks where they are most needed.

3.4 Waste Minimization

Automatic machines optimize material usage, leading to less scrap and overall waste. Efficient bending processes ensure that each piece of material is utilized effectively, contributing to sustainability efforts.

3.5 Versatility

Modern U bolt bending machines can handle a variety of materials and sizes, providing flexibility for manufacturers to adapt to changing market demands without the need for significant capital investment in new machinery.

4. How U Bolt Bending Machines Work

Understanding the operation of **automatic U bolt bending machines** is crucial for appreciating their impact on the industry. These machines employ a combination of technology and engineering principles to perform precise bends.

4.1 CNC Control Systems

Most modern U bolt bending machines utilize **Computer Numerical Control (CNC)** systems. Operators input specifications into the machine, which then executes the bending process with high precision.

4.2 Hydraulic and Electric Mechanisms

These machines often use hydraulic or electric systems to exert the necessary force to bend the metal. This choice of mechanism influences the machine's speed, power, and flexibility.

4.3 Automated Loading and Unloading

Automatic loading and unloading systems streamline the workflow, allowing for continuous production cycles. This automation minimizes downtime and maximizes output.

5. Key Features of Modern U Bolt Bending Machines

To understand the advantages better, let's explore some key features of modern U bolt bending machines:

5.1 User-Friendly Interface

Many machines come equipped with intuitive touch screen interfaces, allowing operators to easily input parameters and monitor the bending process in real-time.

5.2 Multi-Axis Bending Capabilities

Advanced machines feature multi-axis capabilities, enabling them to create complex shapes and angles that traditional machines cannot achieve.

5.3 Robust Construction

Built for durability, these machines are designed to withstand the rigors of constant use in a manufacturing environment, ensuring a long service life.

5.4 Integration with CAD Software

Seamless integration with Computer-Aided Design (CAD) software allows for easy transition from design to production, facilitating rapid prototyping and product development.

5.5 Safety Features

Modern machines are equipped with advanced safety features to protect operators, including emergency stop buttons and safety guards, which ensure a secure working environment.

6. Applications of U Bolt Bending Machines in Various Industries

The versatility of **automatic U bolt bending machines** makes them suitable for a range of applications across various industries:

6.1 Automotive Industry

U bolts are integral components in vehicle suspension systems, and automatic bending machines provide the precision required for safety and performance.

6.2 Construction Sector

In construction, U bolts are used to secure structural elements. The ability to produce large quantities quickly and accurately is a significant advantage in this fast-paced industry.

6.3 Aerospace Manufacturing

The aerospace industry requires components that meet stringent safety standards. Automatic U bolt bending machines deliver the precision and reliability required for this critical sector.

6.4 Furniture Manufacturing

In furniture production, U bolts are commonly used in assembly. The efficiency of automatic machines can significantly cut production times and costs.

6.5 Agricultural Equipment

Agricultural machinery often requires durable U bolts to withstand harsh operating conditions. Automatic machines can produce these components to meet specific strength requirements.

7. Cost Efficiency and Return on Investment

Investing in an **automatic U bolt bending machine** can offer substantial returns. The initial investment can be offset by the following factors:

7.1 Decreased Production Costs

With improved efficiency, companies can lower their per-unit production costs, increasing profit margins.

7.2 Faster Production Times

Reduced cycle times equate to higher output, enabling manufacturers to fulfill orders more swiftly and take on more projects simultaneously.

7.3 Long-Term Durability

Quality machines built for longevity reduce the need for frequent replacements, yielding long-term savings.

7.4 Lower Labor Costs

As previously mentioned, automating the bending process minimizes the need for skilled labor, which can be a significant cost saver for manufacturers.

8. The Future of Metal Fabrication with U Bolt Bending Machines

As technology continues to evolve, the future of **metal fabrication** looks promising with the advancement of U bolt bending machines. Emerging trends include:

8.1 Integration with IoT

The **Internet of Things (IoT)** is poised to revolutionize how machines operate, enabling real-time monitoring and predictive maintenance, thereby enhancing operational efficiency.

8.2 Artificial Intelligence in Manufacturing

AI technologies can further optimize bending processes by analyzing data to improve accuracy and reduce waste, pushing the boundaries of what automatic machines can achieve.

8.3 Sustainability Initiatives

With increasing emphasis on sustainability, the development of machines that minimize energy consumption and material waste will shape the future of U bolt bending technology.

9. Frequently Asked Questions

9.1 What is an automatic U bolt bending machine?

An automatic U bolt bending machine is a specialized piece of equipment designed to bend metal rods into U-shaped bolts with high precision and efficiency.

9.2 How does a U bolt bending machine improve production?

By automating the bending process, these machines reduce production time, improve accuracy, and minimize material waste, leading to cost savings.

9.3 Can these machines handle different materials?

Yes, modern U bolt bending machines are versatile and can work with various materials, including steel, aluminum, and other metals.

9.4 What is the average cost of an automatic U bolt bending machine?

The cost can vary widely based on features and capabilities but generally ranges from a few thousand to tens of thousands of dollars.

9.5 How do I maintain an automatic U bolt bending machine?

Regular maintenance should include lubrication of moving parts, cleaning, and periodic inspections to ensure optimal performance and longevity.

10. Conclusion

Automatic U bolt bending machines represent a significant leap forward in the metal fabrication industry, combining **efficiency**, **precision**, and **cost-effectiveness**. As industries continue to evolve, the demand for high-quality, reliable metal components will only increase. By embracing these advanced machines, manufacturers can not only enhance their production capabilities but also ensure competitiveness in a rapidly changing market. Investing in an automatic U bolt bending machine is not just an operational upgrade; it’s a strategic move towards future-proofing a metal fabrication business.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us