Understanding the Applications of Automatic Single-Head Chamfering Machines in Various Industries

Summary:

Understanding the Applications of Automatic Single-Head Chamfering Machines in Various Industries

Table of Contents

1. Introduction to Automatic Single-Head Chamfering Machines

2. What is Chamfering?

3. How Automatic Single-Head Chamfering Machines Work

4. Benefits of Using Automatic Single-Head Chamfering Machines

5. Applications in the Manufacturing Industry

6. Applicati

Understanding the Applications of Automatic Single-Head Chamfering Machines in Various Industries

Table of Contents

- 1. Introduction to Automatic Single-Head Chamfering Machines

- 2. What is Chamfering?

- 3. How Automatic Single-Head Chamfering Machines Work

- 4. Benefits of Using Automatic Single-Head Chamfering Machines

- 5. Applications in the Manufacturing Industry

- 6. Applications in the Construction Sector

- 7. Applications in the Automotive Industry

- 8. Future Trends in Chamfering Technology

- 9. Conclusion

- 10. Frequently Asked Questions

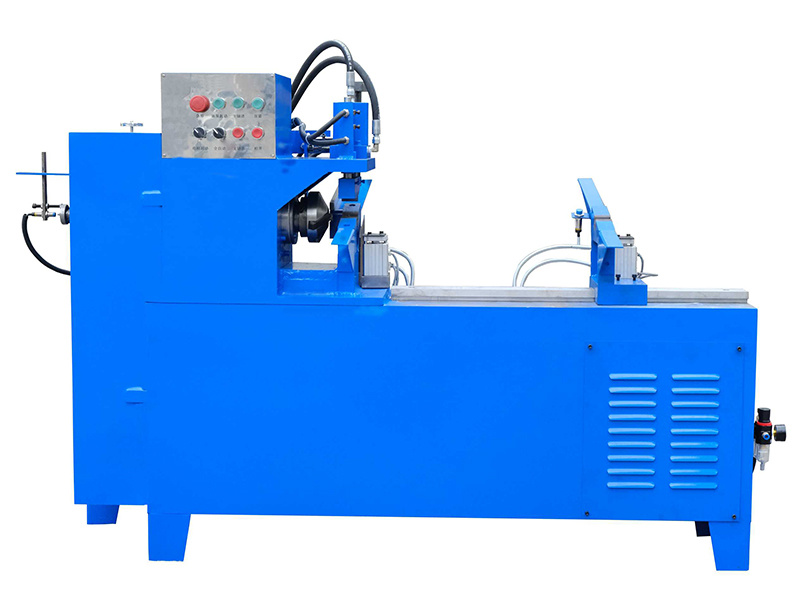

1. Introduction to Automatic Single-Head Chamfering Machines

Automatic Single-Head Chamfering Machines have revolutionized the precision machining landscape across various industries. These machines are designed to create beveled edges on materials, enhancing their performance and aesthetic appeal. By automating the chamfering process, manufacturers significantly increase productivity, reduce labor costs, and maintain consistent quality. In this article, we will thoroughly explore the applications, benefits, and future of these machines in different sectors.

2. What is Chamfering?

Chamfering is the process of beveling the edges of a workpiece, which can be made from various materials, including metal, plastic, and wood. This technique serves multiple purposes:

- **Safety**: Sharpened edges can pose safety risks. Chamfering reduces sharpness, making handling safer.

- **Aesthetics**: Beveled edges provide a polished look, enhancing the visual appeal of products.

- **Functionality**: Chamfered edges can improve the fit and assembly of components, particularly in mechanical applications.

3. How Automatic Single-Head Chamfering Machines Work

The working principle of Automatic Single-Head Chamfering Machines involves a series of mechanical and electronic components that work cohesively to produce precise chamfers. Here’s a breakdown of the process:

- **Material Loading**: The workpieces are automatically fed into the machine using conveyors or feeders.

- **Cutting Mechanism**: Equipped with a single cutting head, the machine applies the necessary force and speed to create accurate bevels.

- **Control System**: Advanced control systems allow for adjustments in speed, depth, and angle, ensuring that every chamfer meets specific requirements.

- **Material Ejection**: Once chamfering is complete, the finished pieces are ejected for further processing or packaging.

4. Benefits of Using Automatic Single-Head Chamfering Machines

Investing in Automatic Single-Head Chamfering Machines brings numerous benefits:

- **Increased Efficiency**: Automation significantly speeds up the chamfering process, allowing for higher production rates.

- **Consistency and Precision**: These machines ensure uniform chamfer dimensions, reducing variability and enhancing product quality.

- **Cost Savings**: By minimizing manual labor and reducing material waste, businesses can achieve significant cost reductions.

- **Flexibility**: Many machines can adapt to different materials and sizes, making them versatile for various manufacturing needs.

5. Applications in the Manufacturing Industry

In the manufacturing industry, Automatic Single-Head Chamfering Machines are invaluable. They are used in:

- **Metal Fabrication**: Creating chamfers on metal components facilitates welding and assembly processes, enhancing structural integrity.

- **Electronics**: Chamfered edges on circuit boards prevent damage during assembly and improve overall performance.

- **General Parts Production**: Many industrial components require chamfering to fit correctly in assemblies, making these machines essential.

6. Applications in the Construction Sector

The construction industry also benefits greatly from chamfering technology. Applications include:

- **Structural Components**: Beveled edges on beams and columns enhance safety and structural performance.

- **Finishing Work**: Chamfering doors and windows improves aesthetics and fit, leading to better insulation and energy efficiency.

- **Pre-Fabricated Structures**: Chamfering in pre-fabrication allows for quicker assembly on-site, reducing labor costs and time.

7. Applications in the Automotive Industry

In the automotive sector, chamfering plays a crucial role in component manufacturing:

- **Engine Parts**: Chamfered edges improve the fit of gears and bearings, reducing wear and tear over time.

- **Body Panels**: Enhancing the aesthetics and seam quality of automotive bodywork through chamfering improves consumer appeal.

- **Safety Features**: Beveling edges on safety components enhances their performance and reliability.

8. Future Trends in Chamfering Technology

The future of Automatic Single-Head Chamfering Machines is bright, with several trends shaping the industry:

- **Smart Technology**: Integration of IoT and AI will allow machines to self-adjust based on real-time feedback, improving efficiency.

- **Sustainability**: Manufacturers are developing machines that minimize energy consumption and material waste, aligning with global sustainability goals.

- **Advanced Materials**: As industries move toward composite and lightweight materials, chamfering machines will adapt to handle these new challenges.

9. Conclusion

Automatic Single-Head Chamfering Machines represent a vital innovation in modern manufacturing, construction, and automotive industries. With their ability to enhance efficiency, maintain precision, and reduce costs, these machines are essential for businesses aiming to stay competitive. As technology continues to evolve, the potential applications and benefits of chamfering machines will only expand, paving the way for new advancements and opportunities.

10. Frequently Asked Questions

What materials can be processed with Automatic Single-Head Chamfering Machines?

These machines can work with a variety of materials, including metals, plastics, and composites.

How does chamfering improve the safety of products?

Chamfering removes sharp edges, reducing the risk of injury during handling and use.

Can Automatic Single-Head Chamfering Machines be used for small-scale production?

Yes, these machines can be tailored for both high-volume and small-scale production needs.

What is the average speed of chamfering operations?

The speed can vary depending on the machine and material, but many machines can process multiple pieces per minute.

Are there maintenance requirements for these machines?

Regular maintenance is essential to ensure optimal performance, including checking and replacing cutting tools and cleaning components.

By understanding the applications and benefits of Automatic Single-Head Chamfering Machines, industries can leverage this technology to enhance productivity and product quality.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us