How Automatic Single-Head Chamfering Machines Enhance Lean Manufacturing Efficiency

Summary:

How Automatic Single-Head Chamfering Machines Enhance Lean Manufacturing Efficiency

Introduction to Lean Manufacturing and Chamfering Machines

In the fast-paced world of manufacturing, efficiency is paramount. Lean manufacturing principles focus on minimizing waste while maximizing productivity. One critical element in achieving this balance is the use of specialized machinery, such as **automat

How Automatic Single-Head Chamfering Machines Enhance Lean Manufacturing Efficiency

Introduction to Lean Manufacturing and Chamfering Machines

In the fast-paced world of manufacturing, efficiency is paramount. Lean manufacturing principles focus on minimizing waste while maximizing productivity. One critical element in achieving this balance is the use of specialized machinery, such as **automatic single-head chamfering machines**. These machines streamline production processes, ensuring that every step contributes to overall efficiency. In this article, we will explore how these machines can significantly enhance lean manufacturing practices.

The Role of Chamfering in Manufacturing

Chamfering is the process of creating a beveled edge on a workpiece, which serves several purposes in manufacturing. These include:

1. Improving Safety

Beveled edges reduce the risk of injuries during handling and assembly. By utilizing **automatic chamfering machines**, manufacturers can ensure that these edges are consistently and accurately processed.

2. Enhancing Aesthetic Appeal

Chamfered edges tend to look more polished and professional. This aesthetic improves the product's marketability and customer satisfaction.

3. Facilitating Assembly and Fit

Properly chamfered edges allow components to fit together more seamlessly. This can significantly speed up the assembly process, reducing labor costs and time.

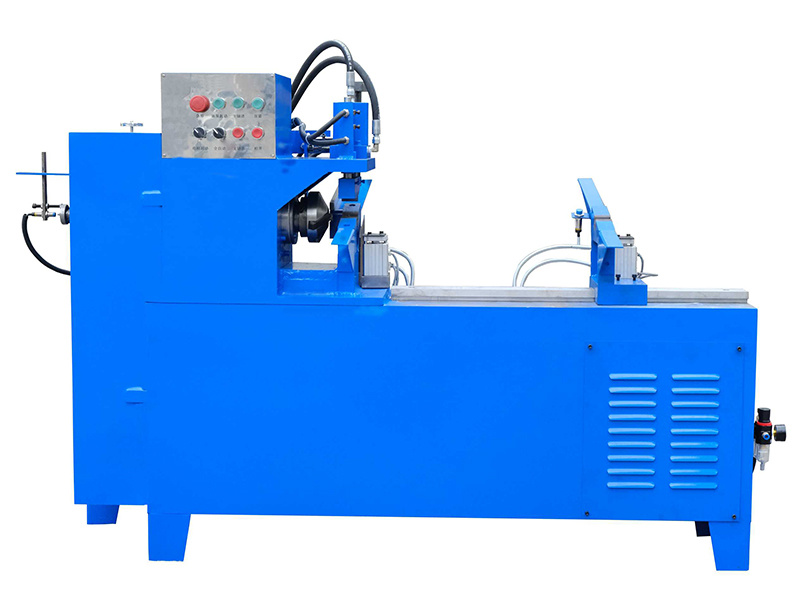

Understanding Automatic Single-Head Chamfering Machines

Automatic single-head chamfering machines are designed to handle the chamfering process with minimal human intervention. Their advantages include:

1. High Precision and Consistency

These machines use advanced technology to ensure that every chamfer is uniform, meeting strict quality standards. This precision is crucial for industries where tolerances are tight.

2. Increased Production Speed

With the automation of the chamfering process, manufacturers can increase their output. These machines operate faster than manual methods, allowing for higher production rates.

3. Reduced Labor Costs

By automating chamfering, businesses can reduce the number of workers needed on the production floor. This not only cuts labor costs but also minimizes the potential for human error.

How Automatic Single-Head Chamfering Machines Fit into Lean Manufacturing

Integrating automatic chamfering machines into a lean manufacturing framework can yield several benefits:

1. Minimizing Waste

Lean manufacturing principles advocate for waste reduction. Automatic chamfering machines minimize material waste by ensuring precise cuts, reducing scrap rates.

2. Streamlining Operations

By automating the chamfering process, manufacturers can streamline their operations. This aligns with the lean principle of creating a smooth flow of production, where each step adds value.

3. Improving Quality Control

With the consistent quality that automatic chamfering machines provide, businesses can enhance their overall quality control processes. This results in fewer defects and returns.

Case Studies: Success Stories in Lean Manufacturing

Several companies have successfully integrated automatic chamfering machines into their lean manufacturing processes:

1. Automotive Industry

In the automotive sector, precision is vital. A leading automotive manufacturer adopted automatic single-head chamfering machines to enhance their assembly line. As a result, they reduced assembly time by 25% and saw a significant decrease in defects.

2. Aerospace Manufacturing

An aerospace components producer implemented these machines to improve safety and precision. The outcome was a 30% reduction in production time, allowing them to meet stringent delivery timelines without compromising quality.

Choosing the Right Automatic Single-Head Chamfering Machine

Selecting the appropriate machine requires careful consideration of various factors:

1. Production Volume

Evaluate the production volume to determine the necessary machine capacity. High-volume operations may require more advanced models with greater automation features.

2. Material Compatibility

Ensure that the chamfering machine can handle the materials you utilize. Different machines are designed for varying materials, from metals to plastics.

3. Precision Needs

Consider the precision requirements of your products. High-precision applications demand machines that provide consistent and accurate chamfering.

Maintenance and Operational Best Practices for Chamfering Machines

To maximize the lifespan and performance of automatic chamfering machines, consider the following best practices:

1. Regular Cleaning and Maintenance

Routine cleaning and maintenance can prevent debris buildup and wear on the machine. Establish a schedule for maintenance checks to ensure optimal performance.

2. Operator Training

Investing in operator training ensures that staff can efficiently and safely operate the machines, preventing costly mistakes and downtime.

3. Monitoring Performance Metrics

Monitor performance metrics such as production speed, scrap rates, and machine downtime. This data can highlight areas for improvement and help in making informed decisions.

Future Trends in Automatic Chamfering Technology

The landscape of manufacturing technology continues to evolve. Some future trends in automatic chamfering machines include:

1. Integration with Industry 4.0

As manufacturing embraces Industry 4.0, expect more chamfering machines to integrate with IoT technology. This will enable real-time monitoring and data analytics, enhancing operational efficiency.

2. Customization and Flexibility

Future machines may offer greater customization options, allowing manufacturers to adjust settings quickly for different production runs.

3. Enhanced Energy Efficiency

With a growing emphasis on sustainability, manufacturers may seek machines that utilize energy-efficient technologies to reduce their environmental impact.

FAQs About Automatic Single-Head Chamfering Machines

1. What are the main advantages of using automatic single-head chamfering machines?

Automatic chamfering machines offer high precision, increased production speed, and reduced labor costs, making them ideal for lean manufacturing.

2. How do chamfering machines contribute to waste reduction?

By ensuring precise cuts, these machines minimize material waste and reduce scrap rates, aligning with lean manufacturing principles.

3. Can automatic chamfering machines handle different materials?

Yes, many automatic chamfering machines are designed to accommodate various materials, including metals and plastics.

4. What maintenance is required for chamfering machines?

Regular cleaning, routine maintenance checks, and operator training are essential for the optimal performance of chamfering machines.

5. How do I choose the right chamfering machine for my business?

Consider factors such as production volume, material compatibility, and precision needs when selecting a chamfering machine.

Conclusion

The integration of **automatic single-head chamfering machines** into lean manufacturing practices represents a significant advancement in optimizing production efficiency. By enhancing precision, reducing waste, and streamlining operations, these machines play a crucial role in achieving the goals of lean manufacturing. As technology continues to evolve, manufacturers can expect even greater innovations in chamfering solutions, paving the way for a more efficient and sustainable future in manufacturing. Embracing these advancements will not only improve immediate production processes but also contribute to long-term operational success.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us