Discover the Advantages of Fully Automatic Double-Head Chamfering Machines

Summary:

In the manufacturing and processing machinery industry, the fully automatic double-head chamfering machine stands as a significant advancement in technology, providing unparalleled efficiency and precision for various applications. This machine is designed to perform chamfering operations on workpieces with two heads, allowing for simultaneous processing, thereby drastically reducing production ti

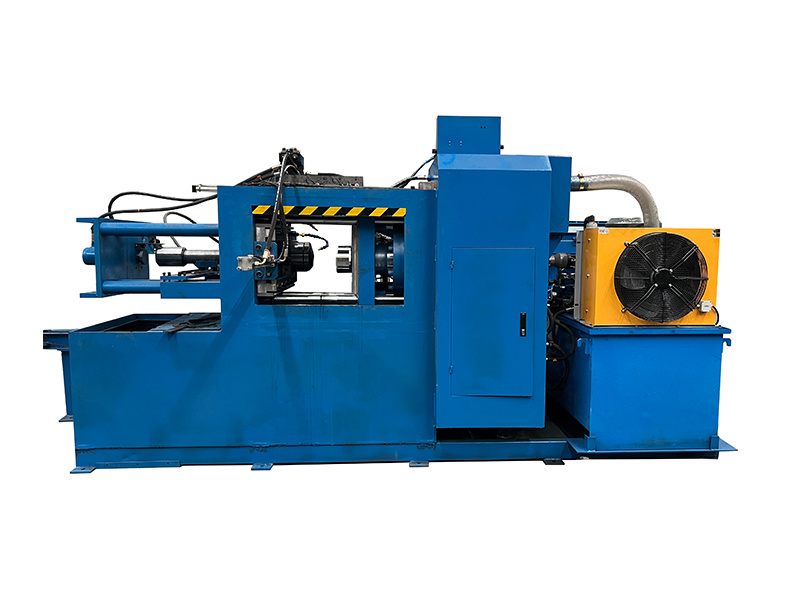

In the manufacturing and processing machinery industry, the fully automatic double-head chamfering machine stands as a significant advancement in technology, providing unparalleled efficiency and precision for various applications. This machine is designed to perform chamfering operations on workpieces with two heads, allowing for simultaneous processing, thereby drastically reducing production time and increasing output.

Chamfering is a crucial operation in the fabrication of components, particularly in metalworking, where edges need to be beveled to prevent damage during assembly or to improve aesthetics. The fully automatic double-head chamfering machine is engineered to address these requirements by providing consistent and high-quality chamfering results.

One of the standout features of this machine is its automation capabilities. Equipped with advanced control systems, it can be programmed to perform various chamfering angles and depths, allowing for customization to meet specific project requirements. This not only enhances the versatility of the machine but also significantly reduces the need for manual intervention, minimizing the risk of human error.

Moreover, the double-head design means that two edges can be chamfered at once, making it especially beneficial for high-volume production facilities. This dual-head operation effectively halves the time required for chamfering, making it an ideal choice for manufacturers looking to increase their throughput without compromising quality.

In addition to speed, the fully automatic double-head chamfering machine also offers enhanced precision. The use of high-quality cutting tools and advanced alignment features ensures that every chamfer is executed with meticulous accuracy. This is particularly important in industries where tolerances are critical, such as aerospace, automotive, and precision engineering.

Maintenance and ease of operation are also important aspects of this machinery. Many models come equipped with user-friendly interfaces that allow operators to monitor performance and make adjustments on-the-fly. Additionally, regular maintenance can be streamlined due to the robust construction of these machines, ensuring long-lasting performance and reliability.

Investing in a fully automatic double-head chamfering machine can lead to significant improvements in operational efficiency, precision, and overall production capacity. For manufacturers aiming to stay competitive in today’s fast-paced market, this technology represents a valuable asset that can drive productivity and enhance product quality.

In summary, the fully automatic double-head chamfering machine is a game-changer in the realm of manufacturing and processing machinery, delivering speed, accuracy, and reliability. Whether you are looking to upgrade your existing processes or implement new ones, understanding the benefits of this innovative equipment can help you make informed decisions in your production strategy.

Chamfering is a crucial operation in the fabrication of components, particularly in metalworking, where edges need to be beveled to prevent damage during assembly or to improve aesthetics. The fully automatic double-head chamfering machine is engineered to address these requirements by providing consistent and high-quality chamfering results.

One of the standout features of this machine is its automation capabilities. Equipped with advanced control systems, it can be programmed to perform various chamfering angles and depths, allowing for customization to meet specific project requirements. This not only enhances the versatility of the machine but also significantly reduces the need for manual intervention, minimizing the risk of human error.

Moreover, the double-head design means that two edges can be chamfered at once, making it especially beneficial for high-volume production facilities. This dual-head operation effectively halves the time required for chamfering, making it an ideal choice for manufacturers looking to increase their throughput without compromising quality.

In addition to speed, the fully automatic double-head chamfering machine also offers enhanced precision. The use of high-quality cutting tools and advanced alignment features ensures that every chamfer is executed with meticulous accuracy. This is particularly important in industries where tolerances are critical, such as aerospace, automotive, and precision engineering.

Maintenance and ease of operation are also important aspects of this machinery. Many models come equipped with user-friendly interfaces that allow operators to monitor performance and make adjustments on-the-fly. Additionally, regular maintenance can be streamlined due to the robust construction of these machines, ensuring long-lasting performance and reliability.

Investing in a fully automatic double-head chamfering machine can lead to significant improvements in operational efficiency, precision, and overall production capacity. For manufacturers aiming to stay competitive in today’s fast-paced market, this technology represents a valuable asset that can drive productivity and enhance product quality.

In summary, the fully automatic double-head chamfering machine is a game-changer in the realm of manufacturing and processing machinery, delivering speed, accuracy, and reliability. Whether you are looking to upgrade your existing processes or implement new ones, understanding the benefits of this innovative equipment can help you make informed decisions in your production strategy.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us