From Manual to Automatic: The Evolution of U Bolt Bending Technology

Summary:

From Manual to Automatic: The Evolution of U Bolt Bending Technology

Introduction to U Bolt Bending Technology

U bolts are essential components widely used in various applications, including automotive, construction, and manufacturing industries. The bending of U bolts involves a crucial process that has evolved significantly over the years. Understanding the transition from manual to automatic

From Manual to Automatic: The Evolution of U Bolt Bending Technology

Introduction to U Bolt Bending Technology

U bolts are essential components widely used in various applications, including automotive, construction, and manufacturing industries. The bending of U bolts involves a crucial process that has evolved significantly over the years. Understanding the transition from manual to automatic bending technology can shed light on the advancements in manufacturing efficiency and precision.

The Importance of U Bolt Bending in Manufacturing

U bolt bending plays a pivotal role in ensuring the structural integrity and functionality of various assemblies. Properly bent U bolts create stable connections in machinery and infrastructure. The significance of this process necessitates accurate and efficient bending techniques to meet the ever-increasing demands of modern manufacturing.

Understanding Manual U Bolt Bending

Historically, U bolt bending was predominantly performed manually. Skilled operators would use hand tools and basic machines to achieve the required shapes. While this method allowed for customizations and unique designs, it was often time-consuming and prone to human error.

Challenges of Manual Bending Techniques

Manual bending techniques faced numerous challenges, including:

- **Inconsistency in Dimensions**: Human errors could lead to variations in sizes, compromising the quality.

- **Time-Consuming Processes**: The lack of automation resulted in longer production times.

- **Labor-Intensive Work**: Manual bending required skilled labor, making it less scalable.

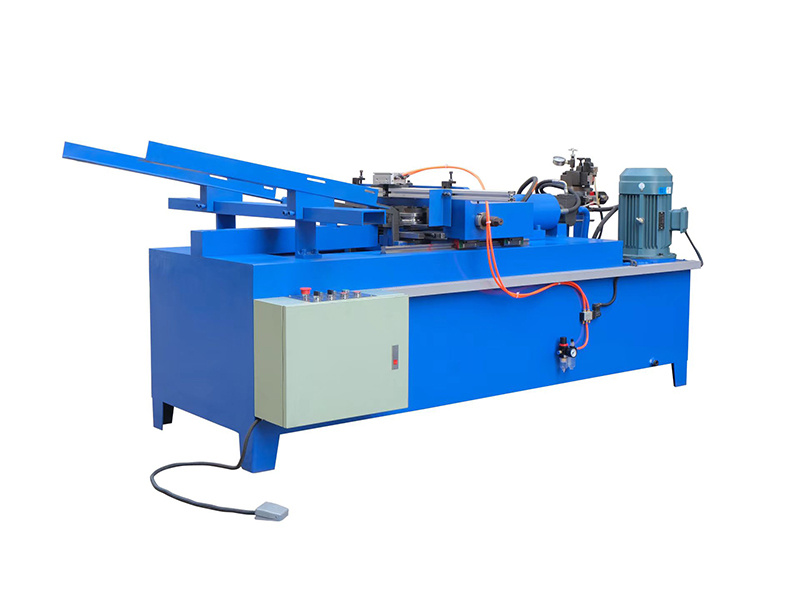

The Birth of Automated U Bolt Bending Machines

The introduction of automated U bolt bending machines marked a revolutionary shift in the manufacturing landscape. These machines utilize advanced technologies to enhance precision and efficiency in the bending process.

Key Features of Automated Bending Machines

Automated machines come equipped with several features that set them apart from manual operations:

- **Computer Numerical Control (CNC)**: CNC technology allows for precise programming of bending angles and dimensions, reducing the risk of error.

- **Speed and Efficiency**: Automated machines significantly reduce production times compared to manual methods.

- **Reduced Labor Costs**: With automation, fewer skilled operators are needed, leading to lower labor expenses.

The Advantages of Automatic U Bolt Bending Technology

Adopting automatic U bolt bending technology offers various advantages that make it the preferred choice in modern manufacturing.

Improved Accuracy and Precision

Automatic machines utilize sophisticated software and hardware to ensure that each U bolt is bent to exact specifications. This level of precision is critical in applications where safety and functionality are paramount.

Enhanced Production Speed

The speed of automated bending machines allows manufacturers to increase their throughput. Faster production times not only boost efficiency but also enable companies to meet tight deadlines without sacrificing quality.

Cost-Effectiveness in the Long Run

While the initial investment in automated technology can be significant, the long-term savings from increased productivity and reduced labor costs make it a financially sound choice for many manufacturers.

Case Studies: The Impact of Automation in the Industry

Examining specific case studies can illustrate the transformative impact of automatic U bolt bending technology.

Case Study 1: Automotive Industry

A leading automotive manufacturer transitioned from manual to automated U bolt bending. The result was a 30% increase in production speed and a 25% decrease in material waste due to improved accuracy.

Case Study 2: Construction Sector

In the construction industry, a company specializing in custom metalwork incorporated automated bending machines. This shift allowed them to fulfill large contracts within tighter timelines while maintaining product quality.

Future Trends in U Bolt Bending Technology

As technology continues to advance, the future of U bolt bending looks promising. Emerging trends include:

Integration of Artificial Intelligence

AI is set to revolutionize the way U bolts are bent, allowing machines to learn from past production runs and optimize processes for even greater efficiency.

Enhanced Materials and Techniques

The development of new materials and bending techniques will further improve the performance and durability of U bolts, leading to innovative applications across various industries.

Sustainability in Manufacturing

With increasing awareness of environmental issues, manufacturers are seeking ways to reduce waste and enhance sustainability. Automated machines can aid in achieving these goals through more efficient material use and energy consumption.

FAQs

1. What are U bolts used for?

U bolts are used to secure objects to a surface, providing stability in various applications, including automotive and construction.

2. How does automatic U bolt bending work?

Automatic U bolt bending machines use CNC technology to precisely bend U bolts according to programmed specifications, ensuring consistency and accuracy.

3. What are the benefits of using automated bending machines?

Benefits include increased production speed, improved accuracy, reduced labor costs, and enhanced flexibility in manufacturing.

4. Can automated machines handle custom U bolt designs?

Yes, automated U bolt bending machines can be programmed to produce custom designs, allowing for flexibility in manufacturing.

5. What is the future of U bolt bending technology?

The future includes advancements in AI, new materials, and a focus on sustainable manufacturing practices.

Conclusion

The evolution of U bolt bending technology from manual to automatic systems has significantly transformed the manufacturing landscape. With improved accuracy, speed, and cost-effectiveness, automation has become an essential component of modern production processes. As we look to the future, advancements in AI and sustainable practices will continue to shape this technology, driving further innovations and efficiencies in the industry. Embracing these changes will enable manufacturers to meet the growing demands of a dynamic market while ensuring the highest standards of quality and performance.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us