Maximizing Efficiency with Automatic U Bolt Bending Machines

Summary:

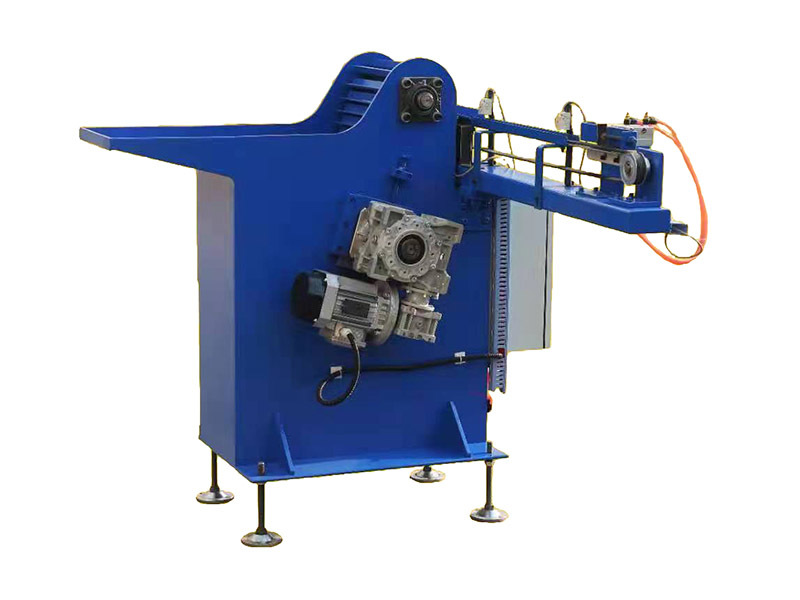

Automatic U Bolt Bending Machines are advanced pieces of equipment designed to streamline the bending process of U-shaped bolts, which are widely used in various applications ranging from construction to automotive industries. These machines are engineered to provide high precision and efficiency, crucial for meeting the demands of modern manufacturing.

One of the primary advantages of using an Au

Automatic U Bolt Bending Machines are advanced pieces of equipment designed to streamline the bending process of U-shaped bolts, which are widely used in various applications ranging from construction to automotive industries. These machines are engineered to provide high precision and efficiency, crucial for meeting the demands of modern manufacturing.

One of the primary advantages of using an Automatic U Bolt Bending Machine is the elimination of manual labor, which not only speeds up production but also reduces the likelihood of human error. Operators can set the specifications for the bending process digitally, ensuring consistent results with minimal variation. This level of automation is particularly beneficial for high-volume production runs where uniformity is essential.

Additionally, these machines often come equipped with advanced software that allows for easy adjustments and programming of different bending angles and dimensions. This flexibility enables manufacturers to quickly adapt to changing production requirements or to customize products for specific client needs. As a result, businesses can respond more swiftly to market demands, improving their competitive edge.

Moreover, the use of an Automatic U Bolt Bending Machine significantly enhances safety in the workplace. Traditional bending processes often involve risks due to manual handling and the use of rudimentary tools. In contrast, automated systems minimize operator exposure to hazardous conditions, as the machine can be programmed to perform tasks with precision, requiring less direct human intervention.

Maintenance is another important factor to consider when utilizing these machines. Regular servicing and upkeep are crucial to ensure optimal performance and longevity. Many manufacturers provide resources for routine maintenance, and understanding these requirements can lead to reduced downtime and increased productivity.

In conclusion, the integration of Automatic U Bolt Bending Machines into manufacturing operations can lead to significant improvements in efficiency, safety, and product quality. By leveraging the latest technology in automation, companies can optimize their bending processes, allowing them to meet both current and future demands in a competitive marketplace. For professionals in the manufacturing sector, investing in such machinery represents a strategic move towards innovation and excellence in production practices.

One of the primary advantages of using an Automatic U Bolt Bending Machine is the elimination of manual labor, which not only speeds up production but also reduces the likelihood of human error. Operators can set the specifications for the bending process digitally, ensuring consistent results with minimal variation. This level of automation is particularly beneficial for high-volume production runs where uniformity is essential.

Additionally, these machines often come equipped with advanced software that allows for easy adjustments and programming of different bending angles and dimensions. This flexibility enables manufacturers to quickly adapt to changing production requirements or to customize products for specific client needs. As a result, businesses can respond more swiftly to market demands, improving their competitive edge.

Moreover, the use of an Automatic U Bolt Bending Machine significantly enhances safety in the workplace. Traditional bending processes often involve risks due to manual handling and the use of rudimentary tools. In contrast, automated systems minimize operator exposure to hazardous conditions, as the machine can be programmed to perform tasks with precision, requiring less direct human intervention.

Maintenance is another important factor to consider when utilizing these machines. Regular servicing and upkeep are crucial to ensure optimal performance and longevity. Many manufacturers provide resources for routine maintenance, and understanding these requirements can lead to reduced downtime and increased productivity.

In conclusion, the integration of Automatic U Bolt Bending Machines into manufacturing operations can lead to significant improvements in efficiency, safety, and product quality. By leveraging the latest technology in automation, companies can optimize their bending processes, allowing them to meet both current and future demands in a competitive marketplace. For professionals in the manufacturing sector, investing in such machinery represents a strategic move towards innovation and excellence in production practices.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us