Understanding Inverted Wire Drawing Machines: A Comprehensive Guide for Metal Processing Professionals

Summary:

In the realm of metal processing, the inverted wire drawing machine plays a crucial role in the production of high-quality wire products. This specialized equipment is designed to draw metal wires through a series of dies, transforming the raw material into thinner, stronger wires suitable for various applications. Understanding the mechanics and benefits of inverted wire drawing machines can sign

In the realm of metal processing, the inverted wire drawing machine plays a crucial role in the production of high-quality wire products. This specialized equipment is designed to draw metal wires through a series of dies, transforming the raw material into thinner, stronger wires suitable for various applications. Understanding the mechanics and benefits of inverted wire drawing machines can significantly enhance operational efficiency and product quality in manufacturing environments.

An inverted wire drawing machine operates by guiding the wire from a spool through a series of progressively smaller dies. The unique design of the inverted machine allows for efficient wire handling, as the wire is drawn downwards rather than upwards. This gravity-assisted mechanism reduces the need for excessive tension, thereby minimizing the risk of wire breakage during the drawing process. Additionally, the inverted configuration enables easier inspection and maintenance, ensuring that machines remain operational with minimal downtime.

One of the primary advantages of utilizing an inverted wire drawing machine is the improved surface finish of the drawn wire. The design facilitates smoother transitions through the dies, reducing friction and promoting uniformity in the wire's diameter. This is particularly beneficial for applications requiring precision, such as in the automotive and aerospace industries, where the integrity and performance of wire products are critical.

Moreover, inverted wire drawing machines are equipped with advanced control systems that allow operators to monitor parameters such as speed, tension, and die wear in real-time. These features enhance the precision of the drawing process, leading to consistent product quality. Furthermore, the ability to quickly adjust these settings contributes to increased flexibility in production runs, accommodating varying wire specifications without significant delays.

For professionals considering the integration of inverted wire drawing machines into their operations, it is essential to evaluate the specific requirements of their manufacturing processes. Factors such as wire material, desired diameter, and production volume should all be taken into account. Additionally, training personnel to operate and maintain these machines effectively will maximize productivity and ensure safety in the workplace.

In conclusion, inverted wire drawing machines represent a vital component in the metal processing sector. By offering improved efficiency, enhanced product quality, and greater operational flexibility, these machines are indispensable for manufacturers aiming to meet the demands of modern industry. Professionals equipped with a thorough understanding of these machines can leverage their capabilities to stay competitive in a constantly evolving market.

An inverted wire drawing machine operates by guiding the wire from a spool through a series of progressively smaller dies. The unique design of the inverted machine allows for efficient wire handling, as the wire is drawn downwards rather than upwards. This gravity-assisted mechanism reduces the need for excessive tension, thereby minimizing the risk of wire breakage during the drawing process. Additionally, the inverted configuration enables easier inspection and maintenance, ensuring that machines remain operational with minimal downtime.

One of the primary advantages of utilizing an inverted wire drawing machine is the improved surface finish of the drawn wire. The design facilitates smoother transitions through the dies, reducing friction and promoting uniformity in the wire's diameter. This is particularly beneficial for applications requiring precision, such as in the automotive and aerospace industries, where the integrity and performance of wire products are critical.

Moreover, inverted wire drawing machines are equipped with advanced control systems that allow operators to monitor parameters such as speed, tension, and die wear in real-time. These features enhance the precision of the drawing process, leading to consistent product quality. Furthermore, the ability to quickly adjust these settings contributes to increased flexibility in production runs, accommodating varying wire specifications without significant delays.

For professionals considering the integration of inverted wire drawing machines into their operations, it is essential to evaluate the specific requirements of their manufacturing processes. Factors such as wire material, desired diameter, and production volume should all be taken into account. Additionally, training personnel to operate and maintain these machines effectively will maximize productivity and ensure safety in the workplace.

In conclusion, inverted wire drawing machines represent a vital component in the metal processing sector. By offering improved efficiency, enhanced product quality, and greater operational flexibility, these machines are indispensable for manufacturers aiming to meet the demands of modern industry. Professionals equipped with a thorough understanding of these machines can leverage their capabilities to stay competitive in a constantly evolving market.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

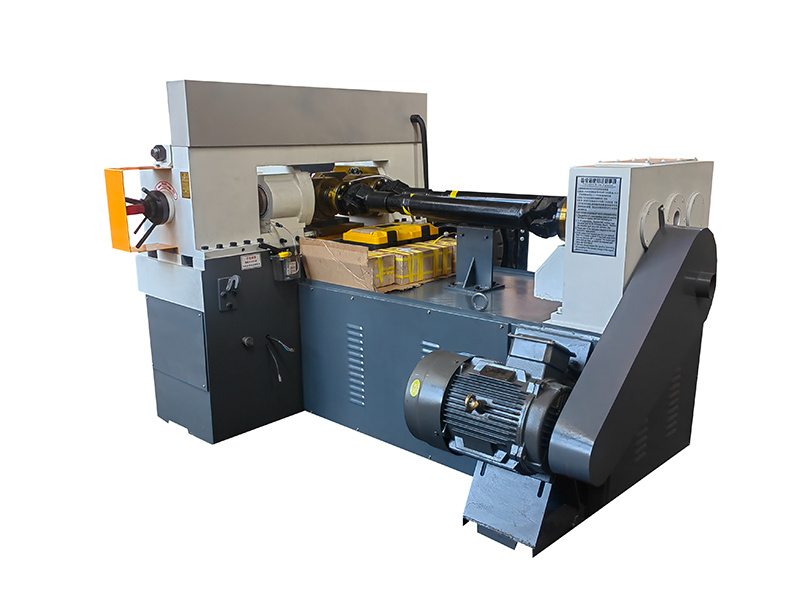

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us