Revolutionizing Metal Fabrication: The Role of Automatic U Bolt Bending Machines

Summary:

Automatic U Bolt Bending Machines are essential tools in the metal fabrication industry, particularly for manufacturers focused on creating high-quality U bolts. These machines are designed to automate the bending process, significantly reducing manual labor while increasing accuracy and production speed. With advancements in technology, modern automatic U bolt bending machines come equipped with

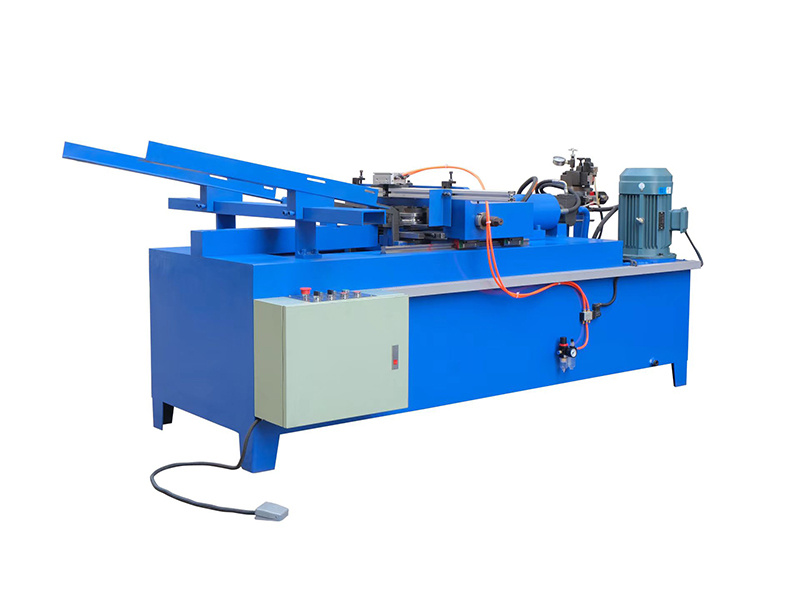

Automatic U Bolt Bending Machines are essential tools in the metal fabrication industry, particularly for manufacturers focused on creating high-quality U bolts. These machines are designed to automate the bending process, significantly reducing manual labor while increasing accuracy and production speed. With advancements in technology, modern automatic U bolt bending machines come equipped with sophisticated features that streamline operations, making them a crucial asset for fabrication workshops.

One of the primary advantages of using an Automatic U Bolt Bending Machine is its ability to handle a variety of materials, including steel, stainless steel, and other alloys. This flexibility allows manufacturers to produce different types of U bolts tailored to specific applications, whether for automotive, construction, or industrial use. The machine's capacity to adjust bending angles and radii ensures that each U bolt meets precise specifications, minimizing errors often associated with manual bending.

Moreover, these machines often incorporate computer numerical control (CNC) technology, enabling operators to program complex bending sequences with ease. This level of automation not only enhances productivity but also significantly reduces the time required to produce multiple U bolts in a single production run. As a result, manufacturers can respond swiftly to changing market demands, ensuring they remain competitive in a fast-paced industry.

The integration of advanced safety features in Automatic U Bolt Bending Machines is another critical aspect. Operators can work with peace of mind, knowing that these machines are designed with protective shields, emergency stop functions, and advanced sensors to prevent accidents. This focus on safety is essential in maintaining a secure working environment, especially in settings where heavy machinery is in operation.

In terms of maintenance, these machines are generally designed for ease of use. Regular maintenance routines can be easily performed, ensuring that the machine operates at peak efficiency throughout its lifespan. Additionally, many manufacturers now offer user-friendly interfaces, making it simpler for operators to manage the bending processes and troubleshoot any potential issues.

In conclusion, Automatic U Bolt Bending Machines are transforming the landscape of metal fabrication. By automating the bending process, these machines not only enhance production efficiency but also ensure high-quality output tailored to specific industry needs. For manufacturers looking to improve their operational capabilities and meet evolving customer demands, investing in an Automatic U Bolt Bending Machine can be a strategic decision that drives growth and innovation in their fabrication processes.

One of the primary advantages of using an Automatic U Bolt Bending Machine is its ability to handle a variety of materials, including steel, stainless steel, and other alloys. This flexibility allows manufacturers to produce different types of U bolts tailored to specific applications, whether for automotive, construction, or industrial use. The machine's capacity to adjust bending angles and radii ensures that each U bolt meets precise specifications, minimizing errors often associated with manual bending.

Moreover, these machines often incorporate computer numerical control (CNC) technology, enabling operators to program complex bending sequences with ease. This level of automation not only enhances productivity but also significantly reduces the time required to produce multiple U bolts in a single production run. As a result, manufacturers can respond swiftly to changing market demands, ensuring they remain competitive in a fast-paced industry.

The integration of advanced safety features in Automatic U Bolt Bending Machines is another critical aspect. Operators can work with peace of mind, knowing that these machines are designed with protective shields, emergency stop functions, and advanced sensors to prevent accidents. This focus on safety is essential in maintaining a secure working environment, especially in settings where heavy machinery is in operation.

In terms of maintenance, these machines are generally designed for ease of use. Regular maintenance routines can be easily performed, ensuring that the machine operates at peak efficiency throughout its lifespan. Additionally, many manufacturers now offer user-friendly interfaces, making it simpler for operators to manage the bending processes and troubleshoot any potential issues.

In conclusion, Automatic U Bolt Bending Machines are transforming the landscape of metal fabrication. By automating the bending process, these machines not only enhance production efficiency but also ensure high-quality output tailored to specific industry needs. For manufacturers looking to improve their operational capabilities and meet evolving customer demands, investing in an Automatic U Bolt Bending Machine can be a strategic decision that drives growth and innovation in their fabrication processes.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us