Unlocking Efficiency: The Role of Automatic Single-Head Chamfering Machines in Modern Manufacturing

Summary:

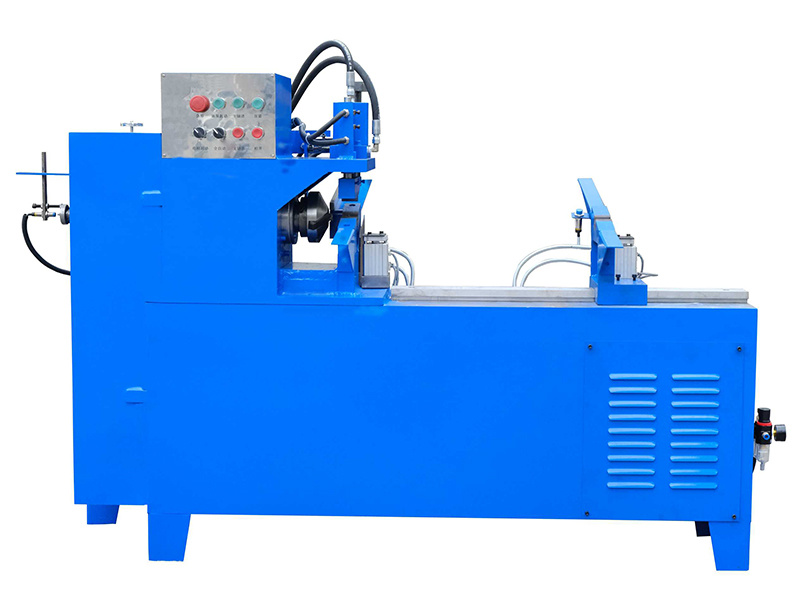

Automatic single-head chamfering machines are specialized tools designed to create a bevel or chamfer on the edges of various materials, including metals and plastics. The primary function of these machines is to smooth out sharp edges, which not only improves the aesthetic appeal of components but also enhances their safety and usability. In a world where precision engineering is paramount, the a

Automatic single-head chamfering machines are specialized tools designed to create a bevel or chamfer on the edges of various materials, including metals and plastics. The primary function of these machines is to smooth out sharp edges, which not only improves the aesthetic appeal of components but also enhances their safety and usability. In a world where precision engineering is paramount, the ability to automate this process can lead to significant efficiency gains.

One of the key advantages of using an automatic single-head chamfering machine is the reduction in manual labor. Traditional chamfering methods are often labor-intensive and time-consuming, requiring skilled operators to perform the task. However, with the advent of automation, these machines can execute chamfering processes quickly and consistently, freeing up human resources for more complex tasks. This shift not only streamlines production but also reduces the likelihood of human error, leading to higher quality outputs.

Moreover, these machines offer a range of settings to accommodate different materials and specifications. For instance, operators can adjust the speed, depth, and angle of the chamfer, allowing for a tailored approach to various projects. This adaptability ensures that manufacturers can meet the diverse needs of their clients without investing in multiple tools or processes.

In addition to speed and adaptability, automatic single-head chamfering machines contribute to cost savings in the long run. By increasing throughput and reducing the time spent on each component, manufacturers can enhance their overall productivity, leading to increased output and profitability. Additionally, the precision offered by these machines minimizes material wastage, further contributing to cost efficiency.

The incorporation of automatic single-head chamfering machines also aligns with the industry's ongoing trend towards Industry 4.0, where interconnected machines and data analytics play a crucial role in optimizing production processes. With the ability to integrate these machines into smart manufacturing systems, companies can leverage real-time data to monitor performance and make informed decisions about production scheduling and resource allocation.

In conclusion, the automatic single-head chamfering machine represents a significant advancement in the manufacturing process, combining efficiency, precision, and adaptability. As industries continue to evolve, embracing such innovations will be crucial for staying competitive and meeting the demands of a dynamic market. Investing in these machines not only enhances operational capabilities but also positions manufacturers for future growth.

One of the key advantages of using an automatic single-head chamfering machine is the reduction in manual labor. Traditional chamfering methods are often labor-intensive and time-consuming, requiring skilled operators to perform the task. However, with the advent of automation, these machines can execute chamfering processes quickly and consistently, freeing up human resources for more complex tasks. This shift not only streamlines production but also reduces the likelihood of human error, leading to higher quality outputs.

Moreover, these machines offer a range of settings to accommodate different materials and specifications. For instance, operators can adjust the speed, depth, and angle of the chamfer, allowing for a tailored approach to various projects. This adaptability ensures that manufacturers can meet the diverse needs of their clients without investing in multiple tools or processes.

In addition to speed and adaptability, automatic single-head chamfering machines contribute to cost savings in the long run. By increasing throughput and reducing the time spent on each component, manufacturers can enhance their overall productivity, leading to increased output and profitability. Additionally, the precision offered by these machines minimizes material wastage, further contributing to cost efficiency.

The incorporation of automatic single-head chamfering machines also aligns with the industry's ongoing trend towards Industry 4.0, where interconnected machines and data analytics play a crucial role in optimizing production processes. With the ability to integrate these machines into smart manufacturing systems, companies can leverage real-time data to monitor performance and make informed decisions about production scheduling and resource allocation.

In conclusion, the automatic single-head chamfering machine represents a significant advancement in the manufacturing process, combining efficiency, precision, and adaptability. As industries continue to evolve, embracing such innovations will be crucial for staying competitive and meeting the demands of a dynamic market. Investing in these machines not only enhances operational capabilities but also positions manufacturers for future growth.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us