Revolutionizing Manufacturing: The Role of Automatic U Bolt Bending Machines

Summary:

In the realm of manufacturing processing machinery, the Automatic U Bolt Bending Machine stands out as a pivotal innovation. This machine is designed to streamline the bending process of U-shaped bolts, which are essential components in various applications, from automotive to construction. By automating the bending process, these machines reduce manual labor, enhance precision, and significantly

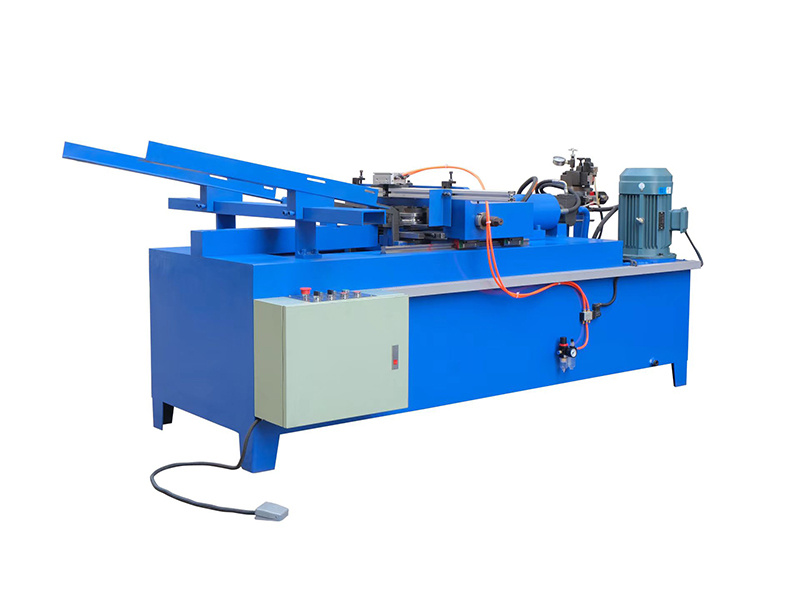

In the realm of manufacturing processing machinery, the Automatic U Bolt Bending Machine stands out as a pivotal innovation. This machine is designed to streamline the bending process of U-shaped bolts, which are essential components in various applications, from automotive to construction. By automating the bending process, these machines reduce manual labor, enhance precision, and significantly improve production speeds.

The operation of an Automatic U Bolt Bending Machine is highly sophisticated. It typically employs advanced CNC (Computer Numerical Control) technology, enabling it to execute complex bending tasks with remarkable accuracy. This level of precision is crucial when producing U bolts that must meet stringent specifications for strength and durability. The machine can be programmed to produce various sizes and shapes of U bolts, which allows manufacturers to respond swiftly to diverse market demands without the need for extensive reconfiguration.

One of the key benefits of utilizing an Automatic U Bolt Bending Machine is the enhancement of productivity. Traditional manual bending processes can be time-consuming and labor-intensive, often leading to inconsistencies in quality. With automation, the bending process is faster, and the output can be significantly increased without compromising on quality. This efficiency not only meets the growing demand in various industries but also reduces operational costs in the long run.

Moreover, the integration of these machines into production lines contributes to better workplace safety. By minimizing the need for manual intervention, the risks associated with handling heavy materials and machinery are reduced, creating a safer environment for workers. Additionally, the accuracy of automated bending minimizes the amount of waste produced during the manufacturing process, aligning with sustainability goals in modern manufacturing practices.

In terms of applications, Automatic U Bolt Bending Machines are widely used in several sectors, including automotive manufacturing, construction, and furniture production. In automotive applications, U bolts are crucial for securing components together, while in construction, they play a vital role in structural integrity. Their versatility makes them an indispensable tool in any manufacturing setup that requires high-quality U bolts.

In conclusion, the Automatic U Bolt Bending Machine represents a significant advancement in manufacturing technology. By enhancing precision, productivity, and safety, it empowers manufacturers to deliver high-quality products efficiently. As industries continue to evolve, investing in such cutting-edge machinery will be essential for staying competitive in the marketplace.

The operation of an Automatic U Bolt Bending Machine is highly sophisticated. It typically employs advanced CNC (Computer Numerical Control) technology, enabling it to execute complex bending tasks with remarkable accuracy. This level of precision is crucial when producing U bolts that must meet stringent specifications for strength and durability. The machine can be programmed to produce various sizes and shapes of U bolts, which allows manufacturers to respond swiftly to diverse market demands without the need for extensive reconfiguration.

One of the key benefits of utilizing an Automatic U Bolt Bending Machine is the enhancement of productivity. Traditional manual bending processes can be time-consuming and labor-intensive, often leading to inconsistencies in quality. With automation, the bending process is faster, and the output can be significantly increased without compromising on quality. This efficiency not only meets the growing demand in various industries but also reduces operational costs in the long run.

Moreover, the integration of these machines into production lines contributes to better workplace safety. By minimizing the need for manual intervention, the risks associated with handling heavy materials and machinery are reduced, creating a safer environment for workers. Additionally, the accuracy of automated bending minimizes the amount of waste produced during the manufacturing process, aligning with sustainability goals in modern manufacturing practices.

In terms of applications, Automatic U Bolt Bending Machines are widely used in several sectors, including automotive manufacturing, construction, and furniture production. In automotive applications, U bolts are crucial for securing components together, while in construction, they play a vital role in structural integrity. Their versatility makes them an indispensable tool in any manufacturing setup that requires high-quality U bolts.

In conclusion, the Automatic U Bolt Bending Machine represents a significant advancement in manufacturing technology. By enhancing precision, productivity, and safety, it empowers manufacturers to deliver high-quality products efficiently. As industries continue to evolve, investing in such cutting-edge machinery will be essential for staying competitive in the marketplace.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us