Inverted Wire Drawing Machines: A Game Changer for Metalworking Industries

Summary:

Inverted Wire Drawing Machines: A Game Changer for Metalworking Industries

Table of Contents

1. Introduction to Inverted Wire Drawing Machines

2. Understanding Wire Drawing in Metalworking

3. What Are Inverted Wire Drawing Machines?

4. Advantages of Inverted Wire Drawing Machines

5. Technological Innovations in Inverted Wire Drawing

6. Applications of Inverted Wire Drawing

Inverted Wire Drawing Machines: A Game Changer for Metalworking Industries

Table of Contents

- 1. Introduction to Inverted Wire Drawing Machines

- 2. Understanding Wire Drawing in Metalworking

- 3. What Are Inverted Wire Drawing Machines?

- 4. Advantages of Inverted Wire Drawing Machines

- 5. Technological Innovations in Inverted Wire Drawing

- 6. Applications of Inverted Wire Drawing Machines

- 7. The Future of Metalworking with Inverted Wire Drawing Machines

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Inverted Wire Drawing Machines

The metalworking industry has witnessed transformative changes over the years, and **inverted wire drawing machines** are at the forefront of this revolution. These machines have redefined the processes involved in wire manufacturing, making them more efficient and precise. As industries worldwide continue to demand higher quality and lower costs, understanding the benefits and functionalities of inverted wire drawing machines becomes essential.

2. Understanding Wire Drawing in Metalworking

Wire drawing is a crucial process in metalworking that involves pulling a metal rod or wire through a series of dies to reduce its diameter and increase its length. This method not only creates wire of varying thicknesses but also enhances the material's mechanical properties. Traditional wire drawing methods can be labor-intensive and often result in significant material waste. In contrast, inverted wire drawing machines introduce innovative techniques that streamline operations and reduce waste, ultimately maximizing productivity.

3. What Are Inverted Wire Drawing Machines?

Inverted wire drawing machines differ from conventional wire drawing equipment primarily in their design and operational mechanics. These machines feature an inverted setup, where the wire is drawn downward, allowing for a more efficient transfer of force and tension. This design minimizes friction and reduces the risk of wire breakage, which commonly occurs in conventional machines. The inverted orientation also facilitates easier maintenance and faster changeovers between different wire sizes.

4. Advantages of Inverted Wire Drawing Machines

The advantages of using inverted wire drawing machines are numerous and impactful. Key benefits include:

4.1 Enhanced Efficiency

Inverted wire drawing machines operate at higher speeds compared to traditional models, enabling manufacturers to produce more wire in a shorter time frame. This increase in throughput leads to reduced production costs and improved profitability.

4.2 Improved Precision and Quality

With sophisticated control systems and advanced technology, inverted wire drawing machines ensure consistent wire quality and diameter. The precision achieved through these machines minimizes defects and waste, leading to a superior final product.

4.3 Reduced Material Waste

The design of inverted wire drawing machines allows for a more effective utilization of raw materials. By minimizing the chances of breakage and ensuring precise dimensions, manufacturers can reduce scrap rates significantly.

4.4 Lower Operational Costs

Despite the initial investment in inverted wire drawing machines, the long-term savings associated with increased efficiency, reduced material waste, and lower energy consumption often outweigh the costs. This makes them a financially sound choice for metalworking companies.

5. Technological Innovations in Inverted Wire Drawing

The evolution of inverted wire drawing machines is heavily influenced by technological advancements. These innovations have introduced automation, digital control systems, and enhanced materials that improve performance and reliability.

5.1 Automation and Smart Technology

Modern inverted wire drawing machines incorporate automation features that streamline the production process. With smart technology, manufacturers can monitor performance metrics in real-time, allowing for proactive maintenance and minimizing downtime.

5.2 Advanced Cooling Systems

Heat generation during the drawing process can affect wire quality. Inverted machines now feature advanced cooling systems that maintain optimal temperatures, ensuring consistent material properties and enhancing overall performance.

5.3 Enhanced Material Handling

Improved material handling systems in inverted wire drawing machines facilitate smooth operations. These systems reduce manual handling and the risk of damage, further contributing to operational efficiency.

6. Applications of Inverted Wire Drawing Machines

Inverted wire drawing machines find applications across various industries, including:

6.1 Automotive Industry

The automotive sector extensively uses wire for components such as springs, cables, and electrical systems. The precision and reliability offered by inverted machines make them an ideal choice for automotive wire production.

6.2 Electrical and Electronics

In the electrical and electronics industry, high-quality wire is critical for functionality. Inverted wire drawing machines produce wire that meets stringent quality standards essential for electrical conductivity.

6.3 Construction and Building

The construction sector requires wire for reinforcement and structural integrity. The strength and durability of wire produced by inverted machines enhance the safety and longevity of construction projects.

6.4 Aerospace and Defense

In aerospace and defense applications, wire must withstand high stress and extreme conditions. The advanced capabilities of inverted wire drawing machines ensure that the wire produced meets rigorous industry standards.

7. The Future of Metalworking with Inverted Wire Drawing Machines

As industries continue to evolve, the role of inverted wire drawing machines will expand. The demand for high-quality, precision-engineered wire products will drive innovations in this sector. With ongoing advancements in technology, we anticipate even greater efficiency, lower environmental impact, and improved product quality.

8. Frequently Asked Questions (FAQs)

8.1 What distinguishes inverted wire drawing machines from traditional ones?

Inverted wire drawing machines feature a downward drawing mechanism, minimizing friction and breakage while enhancing efficiency and precision.

8.2 How do inverted wire drawing machines improve production efficiency?

These machines operate at higher speeds, reduce material waste, and streamline processes, leading to lower production costs and increased output.

8.3 What industries benefit most from inverted wire drawing machines?

Industries such as automotive, electrical and electronics, construction, and aerospace significantly benefit from the precision and quality of wire produced by inverted machines.

8.4 Are there any environmental benefits to using inverted wire drawing machines?

Yes, the reduction in material waste and energy consumption associated with inverted machines contributes to a smaller environmental footprint for manufacturers.

8.5 What are the maintenance requirements for inverted wire drawing machines?

Regular maintenance includes monitoring lubrication, checking for wear and tear, and ensuring the cooling systems are functioning properly to maintain optimal performance.

9. Conclusion

Inverted wire drawing machines represent a significant advancement in the metalworking industry, offering enhanced efficiency, precision, and reduced operational costs. As technology continues to evolve, these machines will play an even more critical role in meeting the growing demands of various industries. By investing in inverted wire drawing technology, manufacturers can ensure they remain competitive while producing high-quality wire products that meet the needs of today’s market.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

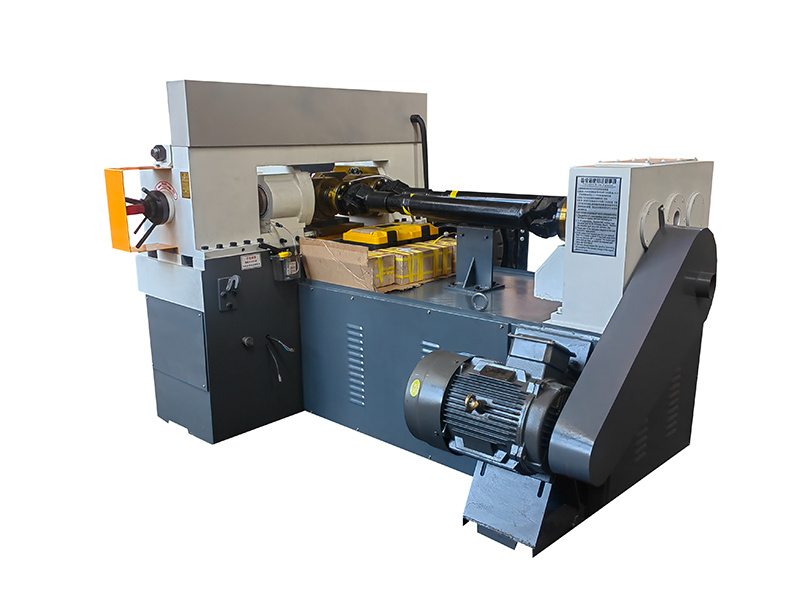

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us