Unlocking Efficiency: The Benefits of Automatic U Bolt Bending Machines in Manufacturing

Summary:

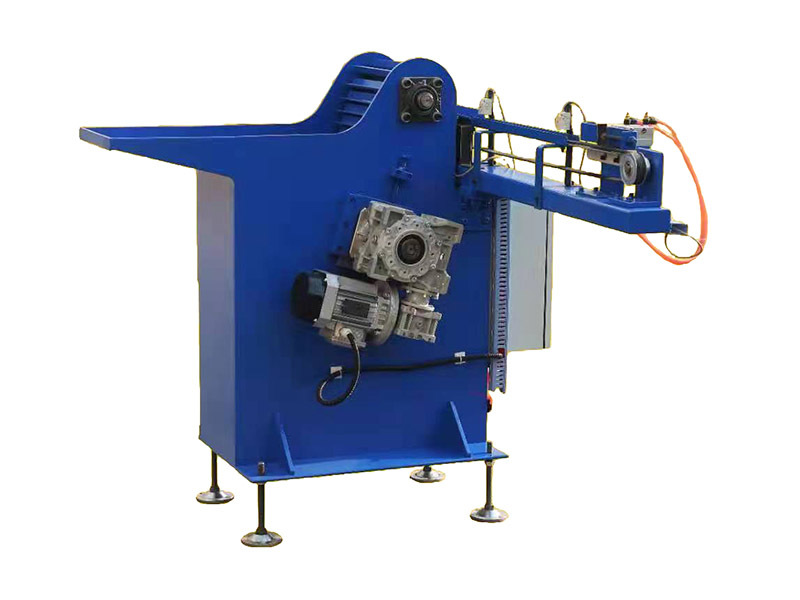

In the ever-evolving landscape of manufacturing and processing machinery, the Automatic U Bolt Bending Machine stands out as a vital tool for modern production lines. This machine is engineered to bend U bolts with exceptional accuracy and speed, significantly enhancing operational efficiency and reducing manual labor.

One of the primary advantages of the Automatic U Bolt Bending Machine is its a

In the ever-evolving landscape of manufacturing and processing machinery, the Automatic U Bolt Bending Machine stands out as a vital tool for modern production lines. This machine is engineered to bend U bolts with exceptional accuracy and speed, significantly enhancing operational efficiency and reducing manual labor.

One of the primary advantages of the Automatic U Bolt Bending Machine is its automation capabilities. Traditional methods of U bolt bending often require extensive manual labor and time-consuming setups, which can lead to inconsistencies in product quality. In contrast, the automatic system streamlines the bending process, allowing for a higher output of uniform products with minimal human intervention. This not only saves time but also reduces the potential for human error, resulting in a more reliable manufacturing process.

Furthermore, these machines are equipped with advanced control systems that facilitate precise adjustments. Operators can easily set the desired specifications for the U bolts, ensuring that each piece meets stringent quality standards. The ability to adjust parameters quickly and accurately means that manufacturers can respond to varying production needs without significant downtime, thus maximizing productivity.

The design of the Automatic U Bolt Bending Machine also contributes to its effectiveness. Many models come with robust construction and high-quality materials that enhance durability and longevity. This ensures that the machine can withstand the rigors of continuous use in a manufacturing environment. Additionally, many machines feature user-friendly interfaces that simplify operation, making it easier for staff to learn and adapt to the technology.

In terms of versatility, Automatic U Bolt Bending Machines can handle a range of materials and sizes, making them suitable for various applications across different industries. Whether you’re producing U bolts for automotive parts, construction, or machinery, these machines can be tailored to meet specific bending requirements, providing manufacturers with the flexibility they need to stay competitive.

Moreover, incorporating an Automatic U Bolt Bending Machine into your production line can lead to significant cost savings over time. By reducing labor costs, minimizing waste, and increasing throughput, manufacturers can improve their overall profit margins while maintaining high levels of quality and reliability.

In conclusion, the Automatic U Bolt Bending Machine is an essential asset for any manufacturing operation looking to enhance efficiency and maintain a competitive edge. With its automation features, precision capabilities, and durability, this machine not only streamlines the bending process but also contributes significantly to overall productivity and quality assurance. Embracing such advanced technology can lead to transformative improvements in your manufacturing processes.

One of the primary advantages of the Automatic U Bolt Bending Machine is its automation capabilities. Traditional methods of U bolt bending often require extensive manual labor and time-consuming setups, which can lead to inconsistencies in product quality. In contrast, the automatic system streamlines the bending process, allowing for a higher output of uniform products with minimal human intervention. This not only saves time but also reduces the potential for human error, resulting in a more reliable manufacturing process.

Furthermore, these machines are equipped with advanced control systems that facilitate precise adjustments. Operators can easily set the desired specifications for the U bolts, ensuring that each piece meets stringent quality standards. The ability to adjust parameters quickly and accurately means that manufacturers can respond to varying production needs without significant downtime, thus maximizing productivity.

The design of the Automatic U Bolt Bending Machine also contributes to its effectiveness. Many models come with robust construction and high-quality materials that enhance durability and longevity. This ensures that the machine can withstand the rigors of continuous use in a manufacturing environment. Additionally, many machines feature user-friendly interfaces that simplify operation, making it easier for staff to learn and adapt to the technology.

In terms of versatility, Automatic U Bolt Bending Machines can handle a range of materials and sizes, making them suitable for various applications across different industries. Whether you’re producing U bolts for automotive parts, construction, or machinery, these machines can be tailored to meet specific bending requirements, providing manufacturers with the flexibility they need to stay competitive.

Moreover, incorporating an Automatic U Bolt Bending Machine into your production line can lead to significant cost savings over time. By reducing labor costs, minimizing waste, and increasing throughput, manufacturers can improve their overall profit margins while maintaining high levels of quality and reliability.

In conclusion, the Automatic U Bolt Bending Machine is an essential asset for any manufacturing operation looking to enhance efficiency and maintain a competitive edge. With its automation features, precision capabilities, and durability, this machine not only streamlines the bending process but also contributes significantly to overall productivity and quality assurance. Embracing such advanced technology can lead to transformative improvements in your manufacturing processes.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us