Comparative Analysis of Manual vs. Automatic Cutting and Threading Machines

Summary:

Comparative Analysis of Manual vs. Automatic Cutting and Threading Machines

Table of Contents

1. Introduction

2. Overview of Manual Cutting and Threading Machines

3. Advantages of Manual Cutting and Threading Machines

4. Disadvantages of Manual Cutting and Threading Machines

5. Overview of Automatic Cutting and Threading Machines

6. Advantages of Automatic Cutting and Thre

Comparative Analysis of Manual vs. Automatic Cutting and Threading Machines

Table of Contents

- 1. Introduction

- 2. Overview of Manual Cutting and Threading Machines

- 3. Advantages of Manual Cutting and Threading Machines

- 4. Disadvantages of Manual Cutting and Threading Machines

- 5. Overview of Automatic Cutting and Threading Machines

- 6. Advantages of Automatic Cutting and Threading Machines

- 7. Disadvantages of Automatic Cutting and Threading Machines

- 8. Which Machine is Right for Your Application?

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction

In the world of manufacturing, choosing the right machine for cutting and threading is crucial for ensuring efficiency, quality, and cost-effectiveness. Over the years, two primary types of machines have emerged: **manual** and **automatic cutting and threading machines**. Each type has its unique features, advantages, and limitations. This article aims to provide a detailed comparative analysis of these two types of machines, helping manufacturers make informed decisions tailored to their specific needs.

2. Overview of Manual Cutting and Threading Machines

Manual cutting and threading machines are operated by human intervention, requiring an operator to control the machine throughout the process. These machines are often simpler in design and provide a more hands-on approach to machining. Operators must possess a keen understanding of the machinery and the materials they are working with to achieve the desired results.

Design and Functionality

Manual machines typically consist of a motor, a cutting tool, and a workpiece holder. The operator manually feeds the workpiece into the cutting area and controls the speed and depth of the cut. This hands-on approach allows for flexibility in production but can also lead to inconsistencies if not operated by a skilled technician.

3. Advantages of Manual Cutting and Threading Machines

**Flexibility** is one of the most significant advantages of manual cutting and threading machines. Operators can adjust settings or switch between tasks more quickly than with automatic machines.

**Lower Initial Cost** is another compelling reason for choosing manual machines. These machines are generally less expensive to purchase and maintain, making them an attractive option for small businesses and workshops.

**Skill Development** is enhanced through the use of manual machines. Operators develop a deeper understanding of machining processes, fostering better craftsmanship and attention to detail.

4. Disadvantages of Manual Cutting and Threading Machines

Despite their advantages, manual machines come with notable **disadvantages**. One major drawback is their **labor-intensive operation**, requiring more workforce hours to complete tasks. This can lead to increased labor costs over time.

**Inconsistent Quality** is another concern. The reliance on human skill means that there may be variations in the quality of the finished product, depending on the operator's experience and focus.

Additionally, **lower production rates** can hinder efficiency. Manual machines are often slower than their automatic counterparts, leading to longer lead times for orders.

5. Overview of Automatic Cutting and Threading Machines

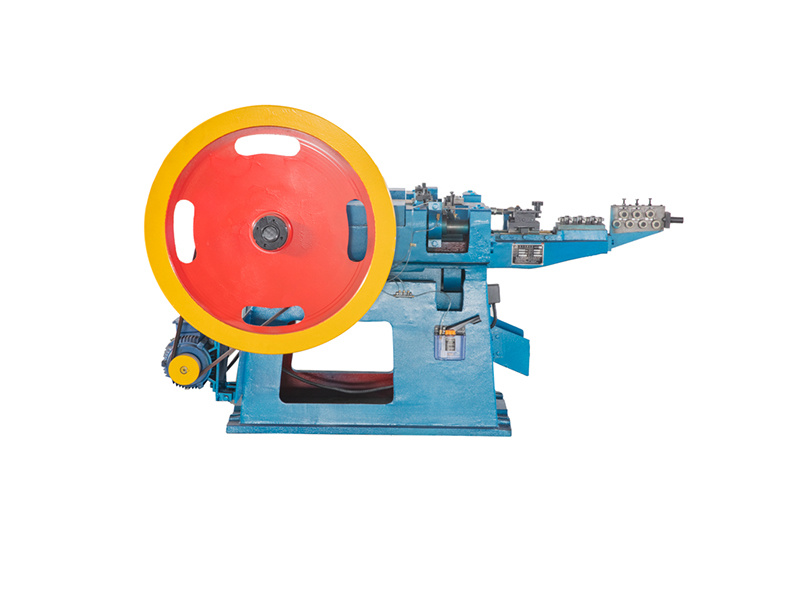

Automatic cutting and threading machines are designed for efficiency and precision, automating the cutting process with minimal human intervention. These machines can handle complex operations and are ideal for high-volume production environments.

Design and Functionality

Automatic machines often include advanced features like programmable logic controllers (PLCs) and computer numerical control (CNC) technology. This allows for precise control over cutting parameters and the ability to produce complex shapes with high repeatability.

6. Advantages of Automatic Cutting and Threading Machines

**Higher Production Rates** are a defining characteristic of automatic machines. These machines can process multiple items simultaneously, significantly reducing production time.

**Consistency in Quality** is another strong point. Automated processes minimize the risk of human error, ensuring that each product meets quality standards.

**Reduced Labor Costs** also make automatic machines appealing. With fewer operators needed, businesses can save on labor expenses while increasing output.

7. Disadvantages of Automatic Cutting and Threading Machines

However, automatic cutting and threading machines are not without their **disadvantages**. The **high initial cost** can be a barrier for some companies, requiring significant investment upfront.

**Complexity in Operation** is another concern. Operating and maintaining automatic machines often requires specialized training, which can increase operational costs.

Additionally, **less flexibility** compared to manual machines can be an issue. Once programmed, automatic machines may struggle to adapt to design changes without incurring downtime.

8. Which Machine is Right for Your Application?

Deciding between manual and automatic cutting and threading machines hinges on various factors, including production volume, material type, and budget constraints.

For low-volume projects or custom work, **manual machines** might be the preferable choice due to their flexibility and lower costs. Conversely, for high-volume manufacturing, **automatic machines** offer speed and consistency, making them the better option.

Furthermore, consider your workforce's skill level and the potential for training. If your team has experience with manual machines and your projects require adaptability, sticking with manual equipment may be wise.

9. Conclusion

The choice between manual and automatic cutting and threading machines significantly impacts production processes in the manufacturing industry. Each type of machine has distinct advantages and disadvantages, requiring careful consideration of specific business needs. By understanding the nuances of both manual and automatic options, manufacturers can make informed decisions that optimize operational efficiency, quality, and cost-effectiveness.

10. Frequently Asked Questions

1. What is the main difference between manual and automatic cutting machines?

The primary difference lies in the level of human intervention required. Manual machines require an operator to control the processes, while automatic machines operate with minimal human input.

2. Are automatic machines more expensive to maintain than manual machines?

Generally, yes. Automatic machines often require specialized training and more complex maintenance, leading to higher maintenance costs over time.

3. Can manual machines produce the same quality as automatic machines?

While skilled operators can produce high-quality work, manual machines are more susceptible to variations in quality. Automatic machines usually provide more consistent results.

4. How do I choose the right machine for my business?

Consider factors such as production volume, the complexity of projects, and budget. Assess your team’s skills and whether flexibility or efficiency is more critical to your operations.

5. Are there hybrid options available that combine features of both types?

Yes, many manufacturers offer hybrid machines that incorporate manual controls alongside automated features, providing a balanced approach to cutting and threading tasks.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us