Enhance Your Production Efficiency with Automatic Cutting and Threading Machines

Summary:

Enhance Your Production Efficiency with Automatic Cutting and Threading Machines

Table of Contents

1. Introduction to Automatic Cutting and Threading Machines

2. The Importance of Cutting and Threading in Manufacturing

3. How Automatic Machines Improve Production Capabilities

3.1 Increased Speed and Efficiency

3.2 Consistency and Quality Control

4. Key Features of Modern Automatic Cu

Enhance Your Production Efficiency with Automatic Cutting and Threading Machines

Table of Contents

1. Introduction to Automatic Cutting and Threading Machines

2. The Importance of Cutting and Threading in Manufacturing

3. How Automatic Machines Improve Production Capabilities

3.1 Increased Speed and Efficiency

3.2 Consistency and Quality Control

4. Key Features of Modern Automatic Cutting and Threading Machines

4.1 Advanced Technology Integration

4.2 User-Friendly Interfaces

5. Types of Automatic Cutting and Threading Machines

5.1 CNC Machines

5.2 Servo-Driven Machines

6. Choosing the Right Automatic Machine for Your Business

6.1 Assessing Your Production Needs

6.2 Budget Considerations

7. Maintenance Tips for Longevity and Efficiency

8. Frequently Asked Questions about Automatic Cutting and Threading Machines

9. Conclusion

1. Introduction to Automatic Cutting and Threading Machines

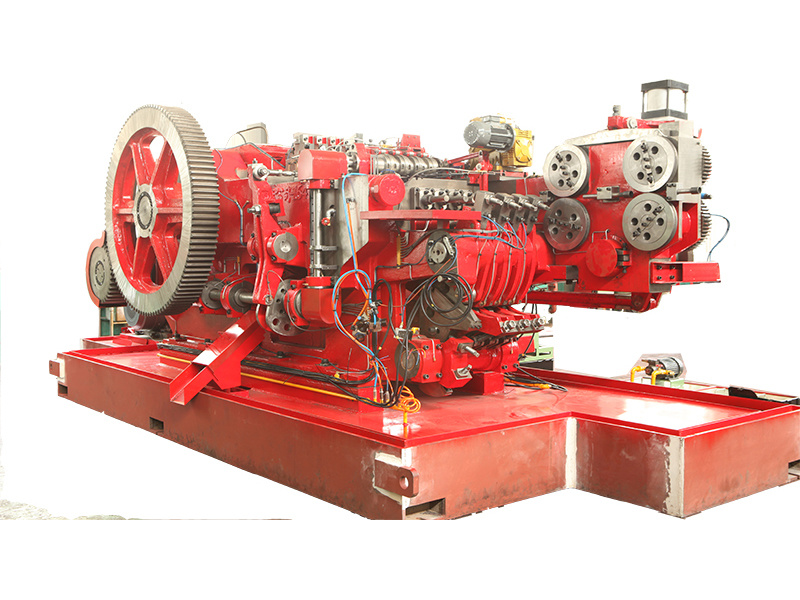

In today’s fast-paced manufacturing environment, the need for precision, speed, and efficiency has never been greater. **Automatic cutting and threading machines** represent a significant evolution in machining technology, designed to streamline processes while enhancing productivity. These machines are engineered to perform cutting and threading operations with minimal human intervention, resulting in impressive gains in production capabilities.

2. The Importance of Cutting and Threading in Manufacturing

Cutting and threading are fundamental processes in manufacturing, impacting everything from material utilization to product quality. **Cutting** refers to the removal of material to shape or size components, while **threading** is the process of creating internal or external threads on a workpiece for fastening purposes. The efficiency and accuracy of these operations are crucial for meeting production deadlines and maintaining quality standards.

3. How Automatic Machines Improve Production Capabilities

Investing in automatic cutting and threading machines significantly boosts productivity. Here are some ways they can enhance production capabilities:

3.1 Increased Speed and Efficiency

Automatic machines operate at higher speeds than manual alternatives, capable of performing multiple tasks in a fraction of the time. This speed translates to shorter lead times and a higher output rate, optimizing production schedules for manufacturers.

3.2 Consistency and Quality Control

With advanced programming and automation, these machines ensure uniformity across products. This consistency minimizes errors and defects, which are common in manual operations. As a result, manufacturers can maintain rigorous quality control standards with less effort.

4. Key Features of Modern Automatic Cutting and Threading Machines

Modern automatic cutting and threading machines come equipped with numerous features that enhance their functionality:

4.1 Advanced Technology Integration

Most contemporary machines integrate technologies such as **CNC (Computer Numerical Control)**, allowing for precise control over cutting paths and threading depths. This advanced technology maximizes accuracy and minimizes the risk of human error.

4.2 User-Friendly Interfaces

Today's machines often come with intuitive interfaces that simplify operation and programming. Operators can quickly learn to use the machine, reducing training time and increasing overall productivity.

5. Types of Automatic Cutting and Threading Machines

Understanding the different types of automatic machines available is essential in selecting the right one for your business needs.

5.1 CNC Machines

**CNC cutting and threading machines** are widely used in various industries due to their versatility and precision. They can handle complex patterns and designs, making them suitable for custom manufacturing.

5.2 Servo-Driven Machines

Servo-driven machines utilize servo motors to enhance movement precision and speed. They are particularly valuable in applications requiring high torque and rapid cycle times, providing manufacturers with a competitive edge.

6. Choosing the Right Automatic Machine for Your Business

Selecting the ideal automatic cutting and threading machine requires careful consideration of several factors:

6.1 Assessing Your Production Needs

Consider the types of materials you work with, the complexity of your designs, and your daily production volume. Understanding these needs will guide you in choosing a suitable machine that aligns with your operational goals.

6.2 Budget Considerations

While investing in high-quality machinery can be costly upfront, it’s important to analyze the long-term benefits. Calculate potential savings in labor costs, material wastage, and production time to justify your investment.

7. Maintenance Tips for Longevity and Efficiency

To ensure the longevity and efficiency of your automatic machines, regular maintenance is crucial. Here are some essential tips:

- **Routine Inspections:** Regularly check for wear and tear on components to prevent minor issues from escalating.

- **Lubrication:** Keep moving parts appropriately lubricated to reduce friction and wear.

- **Software Updates:** Ensure that the machine's software is up to date for optimal performance and features.

8. Frequently Asked Questions about Automatic Cutting and Threading Machines

**Q1: What materials can automatic cutting and threading machines handle?**

A: These machines can work with a wide variety of materials, including metals, plastics, and composites, depending on the machine specifications.

**Q2: How much do automatic cutting and threading machines cost?**

A: Prices vary based on features, capabilities, and brand. Basic models may start around a few thousand dollars, while high-end industrial machines can exceed hundreds of thousands.

**Q3: What is the typical lifespan of an automatic cutting and threading machine?**

A: With proper maintenance, these machines can last for many years, often over a decade, depending on usage and care.

**Q4: Can these machines be customized for specific tasks?**

A: Yes, manufacturers often provide options for customization to suit specific production needs, including tooling and software adaptations.

**Q5: Is training necessary for operators?**

A: While modern machines are designed to be user-friendly, operators will benefit from training to maximize the machine’s capabilities and ensure safe operation.

9. Conclusion

Incorporating automatic cutting and threading machines into your manufacturing process can significantly enhance production capabilities, driving efficiency, accuracy, and consistency. By understanding the types of machines available and selecting the right one for your needs, you can position your business for success in a competitive market. Investing in modern technology not only streamlines operations but also paves the way for future growth and innovation. Embrace these advancements to unlock new levels of productivity and quality in your manufacturing endeavors.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us