The Future of Metal Processing: Innovations in Inverted Wire Drawing Machines

Summary:

The Future of Metal Processing: Innovations in Inverted Wire Drawing Machines

Table of Contents

Introduction to Inverted Wire Drawing Machines

A Brief History of Wire Drawing Technology

Advantages of Inverted Wire Drawing Machines

Recent Innovations in Inverted Wire Drawing Machines

Applications of Inverted Wire Drawing Machines in Metal Processing

Future Trends in Inverted Wire Drawi

The Future of Metal Processing: Innovations in Inverted Wire Drawing Machines

Table of Contents

- Introduction to Inverted Wire Drawing Machines

- A Brief History of Wire Drawing Technology

- Advantages of Inverted Wire Drawing Machines

- Recent Innovations in Inverted Wire Drawing Machines

- Applications of Inverted Wire Drawing Machines in Metal Processing

- Future Trends in Inverted Wire Drawing Technology

- Challenges Facing Inverted Wire Drawing Machines

- Conclusion

- FAQs

Introduction to Inverted Wire Drawing Machines

The field of **metal processing** is constantly evolving, driven by the need for greater efficiency, precision, and sustainability. Among the technological advancements reshaping this industry, **inverted wire drawing machines** stand out as a pivotal innovation. These machines, designed to draw wire by pulling it through a die, offer a variety of advantages over traditional methods. In this article, we will explore the innovations in inverted wire drawing machines and their significant implications for the future of metal processing.

A Brief History of Wire Drawing Technology

Wire drawing has been an essential process in metalworking for centuries. Initially, it involved simple hand-operated tools that gradually evolved into complex machinery. The introduction of **mechanized wire drawing** in the 19th century marked a significant milestone, allowing for faster production rates and improved precision. Over time, the emergence of inverted wire drawing technology further enhanced these capabilities, setting a new standard for efficiency and quality in the metal processing industry.

Advantages of Inverted Wire Drawing Machines

Inverted wire drawing machines present several key advantages that contribute to their growing popularity in the metal processing sector.

1. Enhanced Efficiency

Inverted wire drawing machines are designed to optimize the drawing process, leading to substantial improvements in production speed. Their unique configuration allows for continuous operation, which minimizes downtime and maximizes output.

2. Improved Quality

These machines ensure that the wire produced is more uniform in diameter and surface finish. This consistency is crucial for applications that require high precision, such as aerospace and automotive manufacturing.

3. Reduction in Material Waste

The inverted design minimizes the amount of scrap metal generated during the drawing process, contributing to a more sustainable manufacturing operation. By efficiently utilizing raw materials, manufacturers can reduce costs and environmental impact.

4. Versatility

Inverted wire drawing machines can process a wide range of materials, including various metals and alloys. Their adaptability makes them suitable for diverse applications, further broadening their appeal in the industry.

Recent Innovations in Inverted Wire Drawing Machines

The advancement of technology continues to revolutionize inverted wire drawing machines. Recent innovations focus on improving automation, control systems, and energy efficiency.

1. Automation and Smart Technology

Modern inverted wire drawing machines are increasingly incorporating smart technology, enabling real-time monitoring and control. These systems can adjust parameters automatically to optimize performance, enhancing efficiency and reducing the likelihood of defects.

2. Energy Efficiency

With growing concerns over energy consumption in manufacturing, recent models of inverted wire drawing machines are designed to be more energy-efficient. These machines utilize advanced drive systems and regenerative braking to minimize energy use during operation.

3. Enhanced Material Handling

Innovations in material handling systems, such as automated loading and unloading, streamline the production process. This integration reduces manual labor and increases safety within the manufacturing facility.

4. Advanced Die Technologies

The development of high-performance dies has improved the wire drawing process. These dies provide better wear resistance and can accommodate a wider range of materials, resulting in higher quality output and less frequent replacements.

Applications of Inverted Wire Drawing Machines in Metal Processing

Inverted wire drawing machines are versatile tools utilized across various industries. Their applications include:

1. Automotive Industry

The automotive industry relies heavily on high-quality wire for components such as springs, cables, and electrical wiring. Inverted wire drawing machines ensure consistent quality and precision, which are critical for safety and performance.

2. Aerospace Sector

In aerospace manufacturing, the demand for lightweight yet strong materials is paramount. Inverted wire drawing machines produce wires that meet stringent industry standards, essential for aircraft components and structures.

3. Electrical and Electronics

The electronics industry uses fine wires for circuit boards and connections. The precision and quality achieved through inverted wire drawing machines make them ideal for producing these essential materials.

4. Construction and Infrastructure

In construction, inverted wire drawing machines produce reinforcing wires and cables used in various structural applications. The durability and reliability of these materials are critical for the integrity of buildings and infrastructure projects.

Future Trends in Inverted Wire Drawing Technology

As technology continues to progress, several key trends are emerging in the field of inverted wire drawing machines:

1. Industry 4.0 Integration

The integration of Industry 4.0 principles, including the Internet of Things (IoT) and big data analytics, will revolutionize the way inverted wire drawing machines operate. Enhanced connectivity will allow for better data collection and analysis, leading to improved decision-making and operational efficiency.

2. Sustainable Practices

With an increased focus on sustainability, future innovations will likely emphasize eco-friendly practices. Inverted wire drawing machines will evolve to consume less energy and produce less waste, aligning with global efforts to reduce carbon footprints.

3. Customization and Flexibility

Manufacturers will demand more customized solutions to meet specific production needs. Future machines may feature greater flexibility in terms of adjustable parameters and configurations, allowing for a more tailored approach to wire drawing.

4. Advanced Materials

The development of new materials will also influence inverted wire drawing technology. As manufacturers seek to utilize advanced alloys and composites, machines will need to adapt to accommodate these materials' unique properties.

Challenges Facing Inverted Wire Drawing Machines

Despite the numerous advantages and innovations, the adoption of inverted wire drawing machines is not without challenges.

1. High Initial Costs

The investment required for advanced inverted wire drawing machines can be substantial. Smaller manufacturers may struggle to afford the upfront costs, limiting widespread adoption.

2. Need for Skilled Operators

The complexity of modern machines necessitates a workforce skilled in operating and maintaining advanced equipment. Training programs will be essential to equip personnel with the necessary expertise.

3. Maintenance and Downtime

While inverted wire drawing machines are designed for efficiency, regular maintenance is crucial for optimal performance. Manufacturers must implement effective maintenance schedules to minimize downtime and ensure consistent output.

4. Competition and Market Dynamics

As the demand for inverted wire drawing machines grows, increasing competition may lead to rapid technological advancements, creating a challenge for manufacturers to keep pace with change.

Conclusion

The future of metal processing is undeniably intertwined with innovations in inverted wire drawing machines. As the industry continues to evolve, these machines will play a crucial role in enhancing efficiency, quality, and sustainability. By embracing technological advancements and addressing existing challenges, manufacturers can leverage the full potential of inverted wire drawing machines, paving the way for a more efficient and environmentally friendly metal processing landscape.

FAQs

1. What is an inverted wire drawing machine?

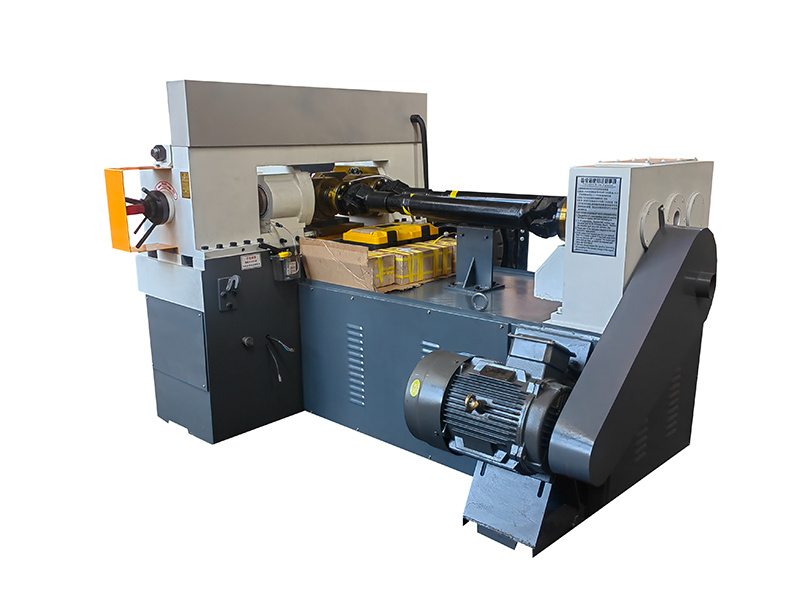

An inverted wire drawing machine is a specialized piece of equipment used to draw metal wire through a die, enhancing the wire's diameter and surface finish while optimizing the production process.

2. What are the benefits of using inverted wire drawing machines?

Inverted wire drawing machines offer several benefits, including enhanced efficiency, improved quality, reduced material waste, and versatility across various materials.

3. How does smart technology improve inverted wire drawing machines?

Smart technology enables real-time monitoring and automated adjustments, optimizing performance and reducing defects, leading to higher production rates and improved product quality.

4. What industries benefit from inverted wire drawing machines?

Industries such as automotive, aerospace, electronics, and construction benefit significantly from inverted wire drawing machines due to their ability to produce high-quality wire for critical applications.

5. What challenges do manufacturers face with inverted wire drawing machines?

Manufacturers may encounter challenges such as high initial costs, the need for skilled operators, maintenance issues, and competition in the market, which can impact the adoption of this technology.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us