Unlocking Efficiency: The Role of Bolt Cold Forging Machines in Manufacturing

Summary:

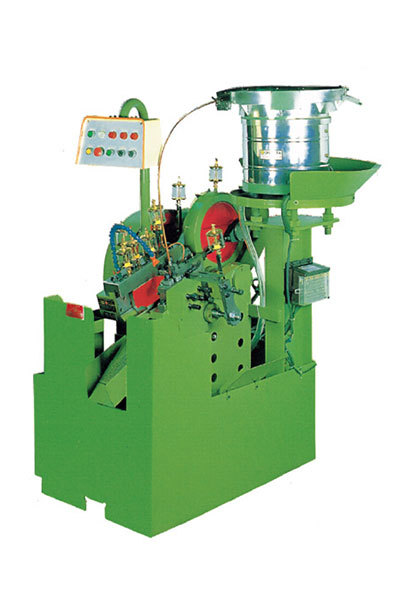

In the manufacturing sector, particularly within the realm of other manufacturing processing machinery, Bolt Cold Forging Machines play a crucial role in the production of high-quality fasteners and components. Cold forging is a process that involves shaping metal at room temperature, which leads to numerous advantages over traditional machining methods.

One of the primary benefits of utilizing a

In the manufacturing sector, particularly within the realm of other manufacturing processing machinery, Bolt Cold Forging Machines play a crucial role in the production of high-quality fasteners and components. Cold forging is a process that involves shaping metal at room temperature, which leads to numerous advantages over traditional machining methods.

One of the primary benefits of utilizing a Bolt Cold Forging Machine is the improvement of material properties. During the cold forging process, the metal’s grain structure is altered, enhancing its strength and durability. This is particularly important for industries requiring robust components, such as automotive and aerospace manufacturing. The machines produce parts that are not only stronger but also have reduced chances of defects, which can lead to cost savings in the long run.

Another significant advantage is the reduction in material waste. Cold forging is an efficient method that utilizes nearly 100% of the raw material, as opposed to machining processes that may generate substantial scrap. This efficiency not only conserves resources but also reduces production costs, making it an economically viable option for manufacturers.

The speed and scalability of Bolt Cold Forging Machines are other key factors that contribute to their growing popularity. These machines can produce large quantities of components quickly, meeting the demands of high-volume production while maintaining precision. This capability allows manufacturers to respond swiftly to market demands without compromising on quality.

In addition to efficiency and cost-effectiveness, Bolt Cold Forging Machines offer versatility in design. They can create a wide range of shapes and sizes, allowing manufacturers to meet specific requirements for various applications. This adaptability makes cold forging an attractive option for businesses seeking to diversify their product offerings.

The operational mechanism of these machines involves applying pressure to metal blanks, which are then shaped into desired forms using dies. This process requires skilled operators who can monitor the machinery to ensure optimal performance and quality control. Proper training and maintenance of the machines are essential to maximize their potential and minimize downtime.

In conclusion, Bolt Cold Forging Machines represent a significant advancement in manufacturing technology. By enhancing material properties, minimizing waste, and increasing production efficiency, they provide a competitive edge to manufacturers in various industries. As businesses continue to seek ways to optimize their production processes, the adoption of cold forging technology is likely to see continued growth, shaping the future of manufacturing.

One of the primary benefits of utilizing a Bolt Cold Forging Machine is the improvement of material properties. During the cold forging process, the metal’s grain structure is altered, enhancing its strength and durability. This is particularly important for industries requiring robust components, such as automotive and aerospace manufacturing. The machines produce parts that are not only stronger but also have reduced chances of defects, which can lead to cost savings in the long run.

Another significant advantage is the reduction in material waste. Cold forging is an efficient method that utilizes nearly 100% of the raw material, as opposed to machining processes that may generate substantial scrap. This efficiency not only conserves resources but also reduces production costs, making it an economically viable option for manufacturers.

The speed and scalability of Bolt Cold Forging Machines are other key factors that contribute to their growing popularity. These machines can produce large quantities of components quickly, meeting the demands of high-volume production while maintaining precision. This capability allows manufacturers to respond swiftly to market demands without compromising on quality.

In addition to efficiency and cost-effectiveness, Bolt Cold Forging Machines offer versatility in design. They can create a wide range of shapes and sizes, allowing manufacturers to meet specific requirements for various applications. This adaptability makes cold forging an attractive option for businesses seeking to diversify their product offerings.

The operational mechanism of these machines involves applying pressure to metal blanks, which are then shaped into desired forms using dies. This process requires skilled operators who can monitor the machinery to ensure optimal performance and quality control. Proper training and maintenance of the machines are essential to maximize their potential and minimize downtime.

In conclusion, Bolt Cold Forging Machines represent a significant advancement in manufacturing technology. By enhancing material properties, minimizing waste, and increasing production efficiency, they provide a competitive edge to manufacturers in various industries. As businesses continue to seek ways to optimize their production processes, the adoption of cold forging technology is likely to see continued growth, shaping the future of manufacturing.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us