Maximizing Efficiency with Double Head Chamfering Machines

Summary:

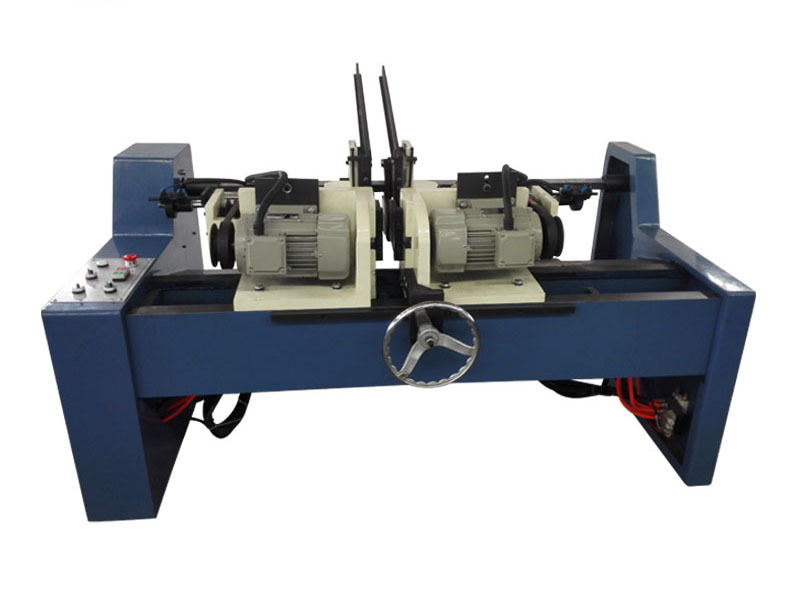

Double head chamfering machines are specialized tools designed to enhance productivity in various manufacturing processes, particularly in machining applications where precise edge treatment is required. These machines are engineered to create bevels and chamfers on metal and other materials, thereby improving the safety and aesthetic of finished products.

One of the primary benefits of a double

Double head chamfering machines are specialized tools designed to enhance productivity in various manufacturing processes, particularly in machining applications where precise edge treatment is required. These machines are engineered to create bevels and chamfers on metal and other materials, thereby improving the safety and aesthetic of finished products.

One of the primary benefits of a double head chamfering machine is its ability to perform dual operations simultaneously. With two cutting heads, these machines can efficiently chamfer both sides of a workpiece in a single pass. This not only saves time compared to single-head alternatives but also ensures uniformity and consistency in the finished edges. Manufacturers looking to increase output without sacrificing quality will find double head chamfering machines particularly advantageous.

In addition to speed, these machines also offer superior versatility. They can handle a variety of materials, including steel, aluminum, and plastic, making them suitable for diverse applications across different sectors. The adjustable settings allow operators to customize the depth and angle of the chamfer, ensuring that specific project requirements are met. This flexibility makes double head chamfering machines ideal for both high-volume production runs and smaller, custom projects.

Moreover, the ergonomic design of modern double head chamfering machines contributes to better operator comfort and safety. Many models are equipped with features such as reduced vibration, easy-to-use controls, and safety guards, which minimize the risk of accidents during operation. Training operators on the proper use and maintenance of these machines further enhances safety and efficiency in the workplace.

Another significant advantage is the cost-effectiveness of using double head chamfering machines. By reducing the time required for operations and minimizing material waste due to inaccurate cuts, businesses can achieve a better return on investment. Furthermore, the durability and reliability of these machines often lead to lower maintenance costs over time, allowing companies to allocate resources more efficiently.

In summary, double head chamfering machines are essential tools that provide numerous benefits in the manufacturing and processing sectors. Their ability to perform dual operations enhances productivity, while their versatility and ergonomic designs contribute to improved safety and operator comfort. For businesses seeking to optimize their chamfering processes, investing in a double head chamfering machine can lead to significant operational improvements and cost savings.

One of the primary benefits of a double head chamfering machine is its ability to perform dual operations simultaneously. With two cutting heads, these machines can efficiently chamfer both sides of a workpiece in a single pass. This not only saves time compared to single-head alternatives but also ensures uniformity and consistency in the finished edges. Manufacturers looking to increase output without sacrificing quality will find double head chamfering machines particularly advantageous.

In addition to speed, these machines also offer superior versatility. They can handle a variety of materials, including steel, aluminum, and plastic, making them suitable for diverse applications across different sectors. The adjustable settings allow operators to customize the depth and angle of the chamfer, ensuring that specific project requirements are met. This flexibility makes double head chamfering machines ideal for both high-volume production runs and smaller, custom projects.

Moreover, the ergonomic design of modern double head chamfering machines contributes to better operator comfort and safety. Many models are equipped with features such as reduced vibration, easy-to-use controls, and safety guards, which minimize the risk of accidents during operation. Training operators on the proper use and maintenance of these machines further enhances safety and efficiency in the workplace.

Another significant advantage is the cost-effectiveness of using double head chamfering machines. By reducing the time required for operations and minimizing material waste due to inaccurate cuts, businesses can achieve a better return on investment. Furthermore, the durability and reliability of these machines often lead to lower maintenance costs over time, allowing companies to allocate resources more efficiently.

In summary, double head chamfering machines are essential tools that provide numerous benefits in the manufacturing and processing sectors. Their ability to perform dual operations enhances productivity, while their versatility and ergonomic designs contribute to improved safety and operator comfort. For businesses seeking to optimize their chamfering processes, investing in a double head chamfering machine can lead to significant operational improvements and cost savings.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us