Understanding the Mechanics Behind Chamfering Machines: A Comprehensive Guide

Summary:

Understanding the Mechanics Behind Chamfering Machines

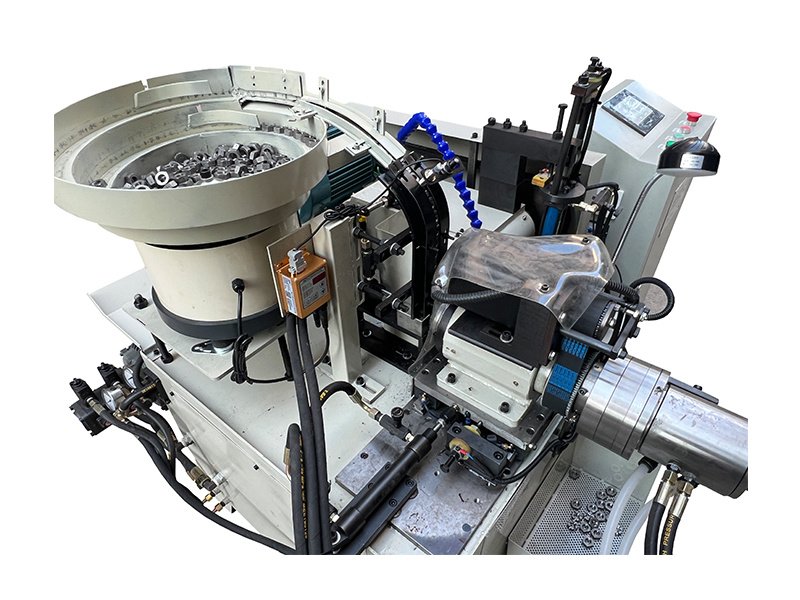

Chamfering machines are crucial in various manufacturing processes, particularly in metalworking and woodworking. They are designed to bevel the edges of materials, creating a smoother finish that improves both functionality and aesthetics. In this comprehensive guide, we delve deep into the mechanics of chamfering machines, discussing their d

Understanding the Mechanics Behind Chamfering Machines

Chamfering machines are crucial in various manufacturing processes, particularly in metalworking and woodworking. They are designed to bevel the edges of materials, creating a smoother finish that improves both functionality and aesthetics. In this comprehensive guide, we delve deep into the mechanics of chamfering machines, discussing their design, operation, benefits, and applications across different industries.

Table of Contents

- 1. Introduction to Chamfering Machines

- 2. How Chamfering Machines Work

- 3. Types of Chamfering Machines

- 4. Key Components of Chamfering Machines

- 5. Applications of Chamfering Machines

- 6. Advantages of Using Chamfering Machines

- 7. Maintenance Tips for Chamfering Machines

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Chamfering Machines

Chamfering machines serve a critical function in manufacturing by creating beveled edges on various materials. These machines provide a quick and efficient way to enhance the quality of components, allowing them to fit perfectly during assembly and improving their overall performance. The process of chamfering removes sharp edges, minimizing the risk of injury during handling and usage. As industries continue to evolve, an understanding of the mechanics behind chamfering machines becomes increasingly important for professionals in the field.

2. How Chamfering Machines Work

Chamfering machines operate on the principle of precision cutting. **These machines utilize various tools and mechanisms to remove material from the edges of a workpiece, creating a beveled surface.** The cutting tools are typically made of high-speed steel or carbide, designed to withstand the rigors of machining.

The operation often involves the following steps:

1. **Clamping the Workpiece:** The material is securely held in place to prevent movement during the cutting process.

2. **Setting the Cutting Angle:** Operators adjust the machine to achieve the desired bevel angle, which can range from 15 to 45 degrees, depending on the application.

3. **Engaging the Cutting Tool:** The chamfering machine activates the cutting tool to begin material removal.

4. **Finishing the Edge:** After the initial cut, the machine may perform additional passes to refine the edge and ensure a smooth finish.

The precision and efficiency of chamfering machines significantly enhance the productivity of manufacturing processes.

3. Types of Chamfering Machines

Chamfering machines come in various types, each catering to specific manufacturing needs. Understanding these types helps businesses choose the right equipment for their operations.

3.1 Manual Chamfering Machines

Manual chamfering machines require operators to control the cutting process. These machines are often used for small-scale operations and in scenarios where precision is critical. They typically feature a hand crank or lever for adjusting the cutting angle and depth.

3.2 Electric Chamfering Machines

Electric chamfering machines offer a more automated solution compared to manual options. **These machines are equipped with electric motors that drive the cutting tools, providing consistent results with minimal operator input.** They are ideal for larger production runs and can handle a wider variety of materials.

3.3 CNC Chamfering Machines

CNC (Computer Numerical Control) chamfering machines represent the pinnacle of modern chamfering technology. These machines use computer programming to control the cutting process, allowing for unparalleled precision and repeatability. CNC machines can be programmed to create complex geometries and adapt to different materials seamlessly. This automation reduces labor costs and increases product quality.

4. Key Components of Chamfering Machines

The effectiveness of chamfering machines relies on several key components, each playing a vital role in the operation. Understanding these components helps in both selecting the right machine and performing maintenance.

1. **Cutting Tool:** The heart of any chamfering machine, cutting tools come in various shapes and sizes, optimized for different materials and edge profiles.

2. **Motor:** Essential for driving the cutting tool, motors must be powerful enough to handle the material being processed.

3. **Work Table:** This is where the workpiece is placed and secured. A robust work table is necessary for stability during the cutting process.

4. **Angle Adjustment Mechanism:** This component allows operators to set the desired bevel angle, which is crucial for achieving the right edge profile.

5. **Control Panel:** For electric and CNC machines, the control panel enables operators to adjust settings and monitor the operation.

5. Applications of Chamfering Machines

Chamfering machines find application in a variety of industries, each benefiting from the smooth edges and improved fit that these machines provide:

- **Manufacturing:** Chamfering machines are widely used in manufacturing components for machinery, automotive parts, and appliances, ensuring safe and efficient assembly.

- **Construction:** In the construction industry, chamfering machines prepare materials for structural applications, enhancing durability and safety.

- **Aerospace:** The aerospace sector relies on chamfering machines for precision components, where every detail matters in terms of performance and safety.

- **Jewelry Making:** In jewelry, chamfering machines can be used to create polished edges on metal and stone, enhancing the overall aesthetic appeal.

6. Advantages of Using Chamfering Machines

Utilizing chamfering machines offers numerous benefits that can enhance both production quality and efficiency:

1. **Improved Safety:** By removing sharp edges, chamfering machines reduce the risk of injuries during handling and assembly.

2. **Increased Efficiency:** Automated and semi-automated chamfering machines speed up the production process, allowing for higher output in shorter time frames.

3. **Consistent Quality:** These machines ensure uniformity in edge finishing, leading to better quality control in manufacturing processes.

4. **Versatility:** Chamfering machines can handle a wide range of materials, from metals to plastics, making them suitable for various applications.

5. **Cost-Effectiveness:** By minimizing manual labor and reducing material waste, chamfering machines can lead to significant cost savings in production.

7. Maintenance Tips for Chamfering Machines

Regular maintenance of chamfering machines is crucial for optimal performance and longevity. Here are essential tips to keep your machines running smoothly:

- **Routine Inspection:** Regularly inspect the cutting tools for wear and tear, replacing them as needed to maintain cutting efficiency.

- **Lubrication:** Ensure that all moving parts are adequately lubricated to prevent friction and wear, which can lead to machine failure.

- **Cleanliness:** Keep the machine clean from debris and metal shavings to prevent contamination and ensure smooth operation.

- **Calibration:** Periodically calibrate the machine to maintain accuracy in cutting angles and depths.

- **Operator Training:** Ensure that all operators are adequately trained in the use and maintenance of the machine to prevent misuse and damage.

8. Frequently Asked Questions

**Q1: What materials can chamfering machines work with?**

A1: Chamfering machines can work with a variety of materials, including metals (steel, aluminum, brass), plastics, and composites.

**Q2: How do I choose the right chamfering machine for my needs?**

A2: Consider factors such as the volume of production, types of materials, required precision, and whether you prefer manual, electric, or CNC machines.

**Q3: What is the typical lifespan of a chamfering machine?**

A3: The lifespan can vary based on usage, maintenance, and quality of the machine, but with proper care, chamfering machines can last for many years.

**Q4: Can chamfering machines be used for other machining tasks?**

A4: While primarily designed for chamfering, some machines may also be capable of performing other tasks, such as deburring or edge rounding, depending on their design.

**Q5: Is operator training necessary for using chamfering machines?**

A5: Yes, proper training is essential to ensure safe and efficient operation, reducing the risk of accidents and machine damage.

9. Conclusion

Understanding the mechanics behind chamfering machines is essential for optimizing manufacturing processes across various industries. From their design and types to their applications and maintenance, these machines play a pivotal role in ensuring the quality and efficiency of production. By investing in the right chamfering machine and implementing regular maintenance practices, businesses can enhance their operations and achieve superior results in their manufacturing endeavors. Embracing the advancements in chamfering technology, particularly in CNC machines, will undoubtedly position industries for success in a competitive market.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us