Exploring the Benefits and Functionality of Double Head Chamfering Machines

Summary:

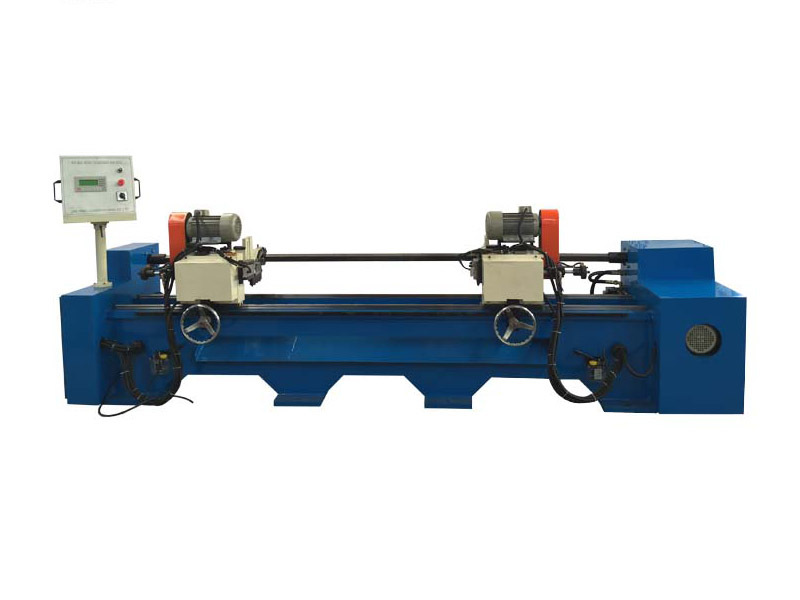

Double head chamfering machines are essential tools in the manufacturing and machining industry, particularly in the realm of electric tools. These machines are designed to create beveled edges on various materials, providing both aesthetic appeal and functional benefits. The unique feature of a double head chamfering machine is its ability to operate with two cutting heads simultaneously, allowin

Double head chamfering machines are essential tools in the manufacturing and machining industry, particularly in the realm of electric tools. These machines are designed to create beveled edges on various materials, providing both aesthetic appeal and functional benefits. The unique feature of a double head chamfering machine is its ability to operate with two cutting heads simultaneously, allowing for increased efficiency and productivity in edge preparation and finishing tasks.

One of the primary advantages of using a double head chamfering machine is the reduction of operational time. Traditional chamfering methods may require multiple passes or setups to achieve the desired edge profile. However, with two heads working in tandem, the machine can process both edges of a workpiece simultaneously, effectively halving the time needed for chamfering operations. This efficiency not only speeds up production but can also lead to cost savings in labor and machine time.

Moreover, double head chamfering machines are versatile and can handle various materials, including metals, plastics, and composites. This adaptability makes them an ideal choice for manufacturers who deal with different types of components and require a reliable solution for edge finishing. The precision offered by these machines ensures that the chamfers are uniform and meet the required specifications, which is crucial for parts that must fit together seamlessly.

In terms of design, many double head chamfering machines are built with user-friendly interfaces and adjustable settings. Operators can easily modify the depth and angle of the chamfer to suit the specific requirements of each job. This level of control allows manufacturers to maintain high standards of quality and consistency, which is vital in competitive markets.

Furthermore, safety features are often integrated into double head chamfering machines to protect operators during use. These may include emergency stop buttons, protective guards, and safety interlocks that ensure the machine cannot operate while access panels are open. Such safety measures are essential in maintaining a secure working environment, particularly in high-volume production settings.

Another consideration is the maintenance of double head chamfering machines. Regular maintenance is crucial to keep the machines in optimal condition and to prevent downtime. Operators should be trained in proper maintenance procedures, which may include routine inspection, cleaning, and lubrication of moving parts.

In conclusion, double head chamfering machines represent a significant advancement in edge finishing technology within the manufacturing industry. Their efficiency, versatility, and precision make them indispensable tools for manufacturers looking to enhance their production processes. By investing in a double head chamfering machine, companies can achieve improved productivity and quality in their machining operations, ultimately leading to greater customer satisfaction and competitive advantages in the market.

One of the primary advantages of using a double head chamfering machine is the reduction of operational time. Traditional chamfering methods may require multiple passes or setups to achieve the desired edge profile. However, with two heads working in tandem, the machine can process both edges of a workpiece simultaneously, effectively halving the time needed for chamfering operations. This efficiency not only speeds up production but can also lead to cost savings in labor and machine time.

Moreover, double head chamfering machines are versatile and can handle various materials, including metals, plastics, and composites. This adaptability makes them an ideal choice for manufacturers who deal with different types of components and require a reliable solution for edge finishing. The precision offered by these machines ensures that the chamfers are uniform and meet the required specifications, which is crucial for parts that must fit together seamlessly.

In terms of design, many double head chamfering machines are built with user-friendly interfaces and adjustable settings. Operators can easily modify the depth and angle of the chamfer to suit the specific requirements of each job. This level of control allows manufacturers to maintain high standards of quality and consistency, which is vital in competitive markets.

Furthermore, safety features are often integrated into double head chamfering machines to protect operators during use. These may include emergency stop buttons, protective guards, and safety interlocks that ensure the machine cannot operate while access panels are open. Such safety measures are essential in maintaining a secure working environment, particularly in high-volume production settings.

Another consideration is the maintenance of double head chamfering machines. Regular maintenance is crucial to keep the machines in optimal condition and to prevent downtime. Operators should be trained in proper maintenance procedures, which may include routine inspection, cleaning, and lubrication of moving parts.

In conclusion, double head chamfering machines represent a significant advancement in edge finishing technology within the manufacturing industry. Their efficiency, versatility, and precision make them indispensable tools for manufacturers looking to enhance their production processes. By investing in a double head chamfering machine, companies can achieve improved productivity and quality in their machining operations, ultimately leading to greater customer satisfaction and competitive advantages in the market.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us