The Essential Guide to U Bolt Bending Machines: Revolutionizing Metal Fabrication

Summary:

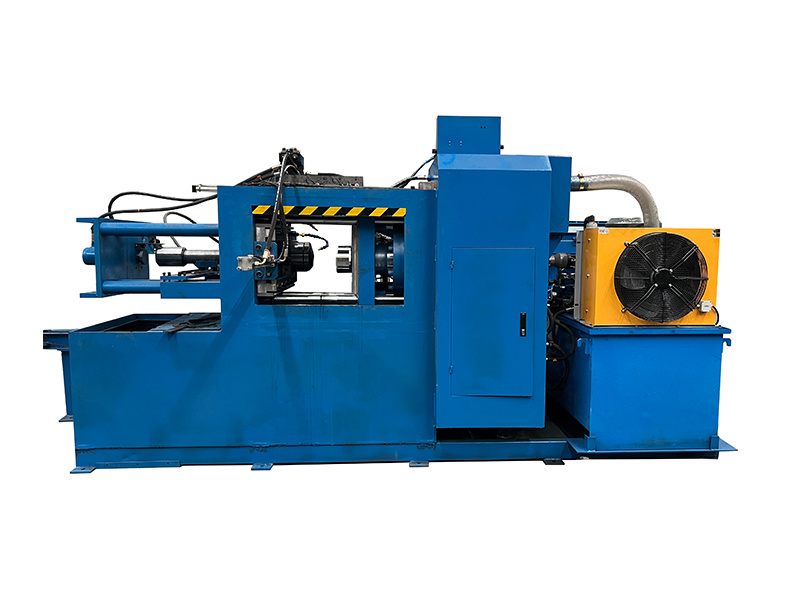

U Bolt Bending Machines are specialized equipment designed for the precise bending of U-bolts, which are crucial components in numerous applications, particularly in the automotive and construction industries. These machines play an essential role in the manufacturing and processing of metal parts, allowing for the production of high-quality U-bolts with consistent specifications.

A U-bolt is esse

U Bolt Bending Machines are specialized equipment designed for the precise bending of U-bolts, which are crucial components in numerous applications, particularly in the automotive and construction industries. These machines play an essential role in the manufacturing and processing of metal parts, allowing for the production of high-quality U-bolts with consistent specifications.

A U-bolt is essentially a bent piece of metal, typically formed into a U-shape, with threads on both ends for securing objects together. The manufacturing process involves cutting, bending, and threading metal rods, and the U Bolt Bending Machine automates much of this work, significantly improving both efficiency and accuracy. By using advanced technology, these machines can produce U-bolts in various sizes and shapes, accommodating different project requirements.

One of the primary benefits of utilizing a U Bolt Bending Machine is its ability to ensure uniformity across all produced items. Unlike manual bending, which can lead to inconsistencies and defects, machines are programmed to maintain precise angles and dimensions. This consistency not only enhances the quality of the finished product but also optimizes the overall workflow, reducing waste and material costs.

Moreover, U Bolt Bending Machines are designed to handle various materials, including steel, stainless steel, and other alloys. This versatility makes them an invaluable asset in any manufacturing environment. The operation of these machines typically requires minimal human intervention, allowing skilled workers to focus on other critical tasks, thereby increasing overall productivity.

In terms of technology, modern U Bolt Bending Machines often feature digital displays and automated controls, enabling operators to program specific bending parameters quickly. This technological advancement not only speeds up the production process but also facilitates easy adjustments for different U-bolt specifications. Furthermore, many machines come equipped with safety features to protect operators, ensuring a safer working environment.

Maintenance of U Bolt Bending Machines is crucial for optimal performance. Regular checks and servicing can prevent downtime and extend the machine's lifespan. Operators should be trained in both the operation and maintenance of these machines to maximize their effectiveness and ensure safety protocols are followed.

In conclusion, U Bolt Bending Machines are a vital component in the manufacturing sector, offering precision, efficiency, and versatility. Their ability to produce high-quality U-bolts quickly and consistently makes them an indispensable tool for manufacturers aiming to enhance their production capabilities. Investing in such machinery not only streamlines the manufacturing process but also contributes to overall business growth and success.

A U-bolt is essentially a bent piece of metal, typically formed into a U-shape, with threads on both ends for securing objects together. The manufacturing process involves cutting, bending, and threading metal rods, and the U Bolt Bending Machine automates much of this work, significantly improving both efficiency and accuracy. By using advanced technology, these machines can produce U-bolts in various sizes and shapes, accommodating different project requirements.

One of the primary benefits of utilizing a U Bolt Bending Machine is its ability to ensure uniformity across all produced items. Unlike manual bending, which can lead to inconsistencies and defects, machines are programmed to maintain precise angles and dimensions. This consistency not only enhances the quality of the finished product but also optimizes the overall workflow, reducing waste and material costs.

Moreover, U Bolt Bending Machines are designed to handle various materials, including steel, stainless steel, and other alloys. This versatility makes them an invaluable asset in any manufacturing environment. The operation of these machines typically requires minimal human intervention, allowing skilled workers to focus on other critical tasks, thereby increasing overall productivity.

In terms of technology, modern U Bolt Bending Machines often feature digital displays and automated controls, enabling operators to program specific bending parameters quickly. This technological advancement not only speeds up the production process but also facilitates easy adjustments for different U-bolt specifications. Furthermore, many machines come equipped with safety features to protect operators, ensuring a safer working environment.

Maintenance of U Bolt Bending Machines is crucial for optimal performance. Regular checks and servicing can prevent downtime and extend the machine's lifespan. Operators should be trained in both the operation and maintenance of these machines to maximize their effectiveness and ensure safety protocols are followed.

In conclusion, U Bolt Bending Machines are a vital component in the manufacturing sector, offering precision, efficiency, and versatility. Their ability to produce high-quality U-bolts quickly and consistently makes them an indispensable tool for manufacturers aiming to enhance their production capabilities. Investing in such machinery not only streamlines the manufacturing process but also contributes to overall business growth and success.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us