Why You Should Consider a Double Head Chamfering Machine for Your Workshop

Summary:

Why You Should Consider a Double Head Chamfering Machine for Your Workshop

Understanding the Importance of Chamfering Machines in Manufacturing

Chamfering is a crucial process in manufacturing, especially in industries that require precision machining. A chamfer is essentially a transitional edge between two faces of an object, typically created to remove sharp edges and enhance aesthetics. In thi

Why You Should Consider a Double Head Chamfering Machine for Your Workshop

Understanding the Importance of Chamfering Machines in Manufacturing

Chamfering is a crucial process in manufacturing, especially in industries that require precision machining. A chamfer is essentially a transitional edge between two faces of an object, typically created to remove sharp edges and enhance aesthetics. In this context, the double head chamfering machine plays a vital role, providing efficient and precise results that meet the demands of modern manufacturing.

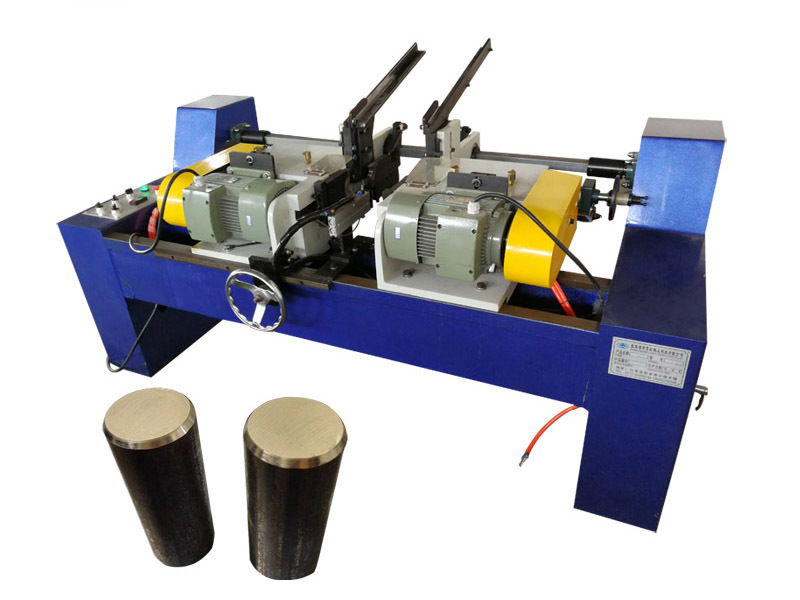

What is a Double Head Chamfering Machine?

A double head chamfering machine features two cutting heads that work simultaneously, allowing for faster and more efficient chamfering. This innovative design not only saves time but also ensures a high level of accuracy in the machining process. These machines can handle a variety of materials, including metals, plastics, and composites, making them versatile tools in any workshop.

Key Features of Double Head Chamfering Machines

1. **Dual Cutting Heads**: The primary feature that distinguishes these machines from single head alternatives is the presence of two cutting heads, which can process two edges at once.

2. **Adjustable Cutting Depth**: Users can adjust the cutting depth to accommodate different thicknesses and material types, ensuring optimal results for various applications.

3. **User-Friendly Controls**: Modern double head chamfering machines come equipped with intuitive controls that make operation easier, even for those who are new to machining.

4. **Robust Construction**: Designed to endure the rigors of a manufacturing environment, these machines are typically built from high-quality materials that ensure longevity.

5. **Energy Efficiency**: Many models feature energy-efficient motors that help reduce operational costs while maintaining high-performance standards.

Why Choose a Double Head Chamfering Machine?

Investing in a double head chamfering machine can bring significant advantages to your workshop. Here are some compelling reasons to consider this equipment:

Enhanced Productivity and Efficiency

In a competitive manufacturing landscape, time is of the essence. Double head chamfering machines excel in productivity, as their dual-cutting capability allows for simultaneous processing. This means you can complete tasks in half the time, helping you meet tight deadlines and increase output.

Superior Precision and Quality

When it comes to precision machining, quality is non-negotiable. Double head chamfering machines are designed to deliver consistent and high-quality results. Their advanced technology minimizes human error, ensuring that every chamfer is uniform and meets the specified tolerances.

Cost-Effectiveness in the Long Run

While the initial investment in a double head chamfering machine may be higher than that of a single head model, the long-term savings are significant. Increased productivity leads to lower labor costs and reduced machine time, ultimately enhancing your bottom line.

Versatility in Applications

These machines are not limited to a specific type of material or application. Whether you're working with aluminum, stainless steel, or plastic, a double head chamfering machine can handle a diverse range of tasks. This versatility makes it an invaluable asset in any workshop.

How to Choose the Right Double Head Chamfering Machine

Selecting the right double head chamfering machine for your workshop involves several considerations to ensure you make an informed decision.

Assess Your Production Needs

Before making a purchase, evaluate your production volume and the types of materials you typically work with. Understanding your specific needs will help you choose a machine that fits seamlessly into your workflow.

Consider the Machine Specifications

Different models come with varying specifications, including cutting speed, motor power, and weight. Pay attention to these details to ensure the machine aligns with your operational requirements.

Look for Additional Features

Some machines offer advanced features such as automatic feeding systems, digital displays, and programmable settings. These enhancements can further increase efficiency and ease of use.

Research Manufacturer Reputation

Investing in reputable brands is crucial. Research manufacturers and read reviews from other users to gauge reliability and customer service experiences. A well-established manufacturer typically provides better support and warranty options.

Maintenance Tips for Double Head Chamfering Machines

To ensure longevity and optimal performance of your double head chamfering machine, proper maintenance is essential.

Regular Cleaning

Dust and debris can accumulate in the machine's components, leading to decreased performance. Regularly clean the machine, focusing on the cutting heads and feed mechanisms.

Lubrication of Moving Parts

Ensure that all moving parts are adequately lubricated to prevent wear and tear. Refer to the manufacturer's guidelines for the recommended lubrication schedule and materials.

Calibration and Adjustment

Periodically check the calibration of the machine to maintain precise cutting depth and alignment. Adjustments may be necessary depending on the type of material and specific production requirements.

Common Applications of Double Head Chamfering Machines

Double head chamfering machines find use across various industries due to their efficiency and versatility.

Metal Fabrication

In metal fabrication, these machines are utilized to chamfer edges of plates and profiles, ensuring a smooth finish and improved joint quality for welding processes.

Automotive Manufacturing

The automotive industry leverages double head chamfering machines for processing components such as brackets and frames, where precision is critical for safety and performance.

Construction and Carpentry

In construction, double head chamfering machines can be used to prepare wooden and composite materials, providing a polished finish that enhances the appearance of structures.

Frequently Asked Questions (FAQs)

1. What are the advantages of using a double head chamfering machine over a single head model?

Double head chamfering machines allow for simultaneous processing of two edges, enhancing productivity and efficiency while maintaining high precision.

2. Can a double head chamfering machine handle different materials?

Yes, these machines are versatile and can work with various materials, including metals, plastics, and composites.

3. What maintenance is required for a double head chamfering machine?

Regular cleaning, lubrication of moving parts, and calibration are essential maintenance tasks to ensure optimal performance.

4. How do I choose the right double head chamfering machine for my needs?

Assess your production needs, consider machine specifications, look for additional features, and research the manufacturer's reputation before making a selection.

5. What is the typical lifespan of a double head chamfering machine?

With proper maintenance, a double head chamfering machine can last several years, but the lifespan may vary based on usage and care.

Conclusion

In conclusion, integrating a double head chamfering machine into your workshop can significantly enhance your manufacturing capabilities. From increased productivity and precision to cost-effectiveness and versatility, the benefits are clear. By choosing the right machine and maintaining it properly, you can ensure that your workshop remains competitive in an ever-evolving industry. Investing in this advanced equipment is not just a step toward upgrading your operations but a commitment to quality and efficiency that will pay off in the long run.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us