Understanding the Benefits and Functionality of Double Head Chamfering Machines

Summary:

Double head chamfering machines play a crucial role in the manufacturing and machining industry by providing efficient and precise edge finishing. These machines are designed to bevel the edges of materials, typically metal, to a specific angle, thus ensuring smooth and safe edges that facilitate further processing and assembly. In this article, we will delve into the functionalities, advantages,

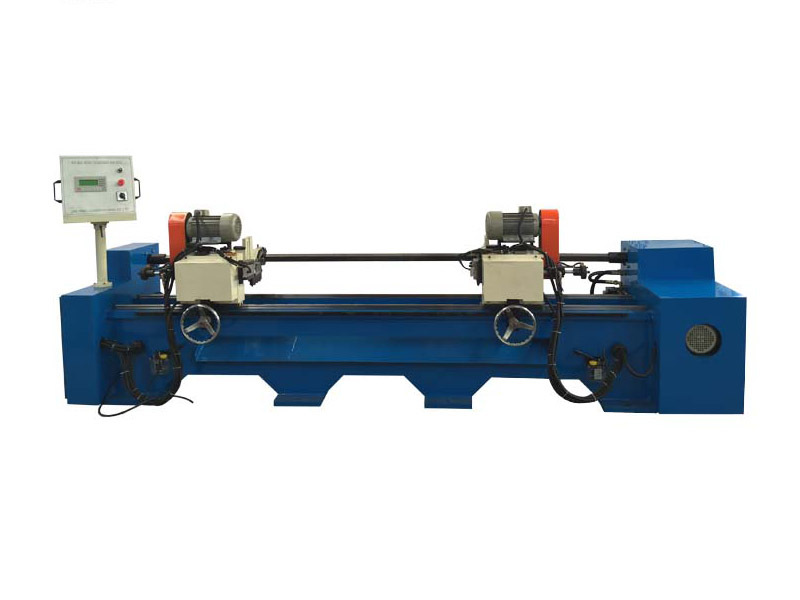

Double head chamfering machines play a crucial role in the manufacturing and machining industry by providing efficient and precise edge finishing. These machines are designed to bevel the edges of materials, typically metal, to a specific angle, thus ensuring smooth and safe edges that facilitate further processing and assembly. In this article, we will delve into the functionalities, advantages, and applications of double head chamfering machines, shedding light on their importance in modern manufacturing.

One of the primary benefits of a double head chamfering machine is its efficiency. Unlike single-head machines that can only process one edge at a time, double head machines can simultaneously work on two edges. This capability significantly reduces production time and increases output, making it an invaluable asset for businesses that require high-volume production with tight deadlines. Moreover, the use of advanced technologies in these machines allows for precise control of the chamfering angle and depth, ensuring consistency across all finished pieces.

In addition to efficiency, double head chamfering machines improve the quality of finished products. The chamfering process not only smooths out sharp edges but also prepares the material for further treatments, such as welding, painting, or assembly. A well-executed chamfer can prevent issues like cracking, rusting, and other forms of deterioration, thereby enhancing the durability of the final product. Furthermore, the precision offered by double head machines minimizes the risk of human error, ensuring that each piece meets the desired specifications.

The versatility of double head chamfering machines is another significant advantage. They are suitable for various materials, including steel, aluminum, and plastic, making them ideal for a wide range of applications in different industries. From automotive to aerospace, and even construction, these machines help manufacturers achieve the necessary standards for edge finishing.

Maintenance and operation of double head chamfering machines also tend to be user-friendly. Many modern machines come equipped with intuitive controls and safety features, allowing operators to work efficiently and safely. Regular maintenance is essential to ensure optimal performance and longevity of the machine, but with proper care, these machines can serve businesses effectively for many years.

In conclusion, double head chamfering machines are indispensable tools in the manufacturing and machining sectors. Their ability to enhance productivity, improve quality, and accommodate a variety of materials makes them a preferred choice for manufacturers looking to streamline their production processes. Investing in a double head chamfering machine can lead to significant improvements in operational efficiency and product quality, positioning businesses for success in a competitive market.

One of the primary benefits of a double head chamfering machine is its efficiency. Unlike single-head machines that can only process one edge at a time, double head machines can simultaneously work on two edges. This capability significantly reduces production time and increases output, making it an invaluable asset for businesses that require high-volume production with tight deadlines. Moreover, the use of advanced technologies in these machines allows for precise control of the chamfering angle and depth, ensuring consistency across all finished pieces.

In addition to efficiency, double head chamfering machines improve the quality of finished products. The chamfering process not only smooths out sharp edges but also prepares the material for further treatments, such as welding, painting, or assembly. A well-executed chamfer can prevent issues like cracking, rusting, and other forms of deterioration, thereby enhancing the durability of the final product. Furthermore, the precision offered by double head machines minimizes the risk of human error, ensuring that each piece meets the desired specifications.

The versatility of double head chamfering machines is another significant advantage. They are suitable for various materials, including steel, aluminum, and plastic, making them ideal for a wide range of applications in different industries. From automotive to aerospace, and even construction, these machines help manufacturers achieve the necessary standards for edge finishing.

Maintenance and operation of double head chamfering machines also tend to be user-friendly. Many modern machines come equipped with intuitive controls and safety features, allowing operators to work efficiently and safely. Regular maintenance is essential to ensure optimal performance and longevity of the machine, but with proper care, these machines can serve businesses effectively for many years.

In conclusion, double head chamfering machines are indispensable tools in the manufacturing and machining sectors. Their ability to enhance productivity, improve quality, and accommodate a variety of materials makes them a preferred choice for manufacturers looking to streamline their production processes. Investing in a double head chamfering machine can lead to significant improvements in operational efficiency and product quality, positioning businesses for success in a competitive market.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us