Unlocking Efficiency: The Benefits of Using an Automatic U Bolt Bending Machine

Summary:

Unlocking Efficiency: The Benefits of Using an Automatic U Bolt Bending Machine

Table of Contents

Introduction to Automatic U Bolt Bending Machines

What is U Bolt Bending?

The Importance of U Bolts in Manufacturing

Benefits of Using Automatic U Bolt Bending Machines

Enhanced Precision and Consistency

Increased Efficiency and Speed

Cost-

Unlocking Efficiency: The Benefits of Using an Automatic U Bolt Bending Machine

Table of Contents

- Introduction to Automatic U Bolt Bending Machines

- What is U Bolt Bending?

- The Importance of U Bolts in Manufacturing

- Benefits of Using Automatic U Bolt Bending Machines

- Enhanced Precision and Consistency

- Increased Efficiency and Speed

- Cost-Effectiveness and Reduced Labor Costs

- Space-Saving Design and Automation

- Key Features of Automatic U Bolt Bending Machines

- How to Choose the Right U Bolt Bending Machine

- Case Studies: Success Stories with Automatic U Bolt Bending Machines

- The Future of U Bolt Bending Technology

- Conclusion: Embracing the Future of U Bolt Bending

- FAQs

Introduction to Automatic U Bolt Bending Machines

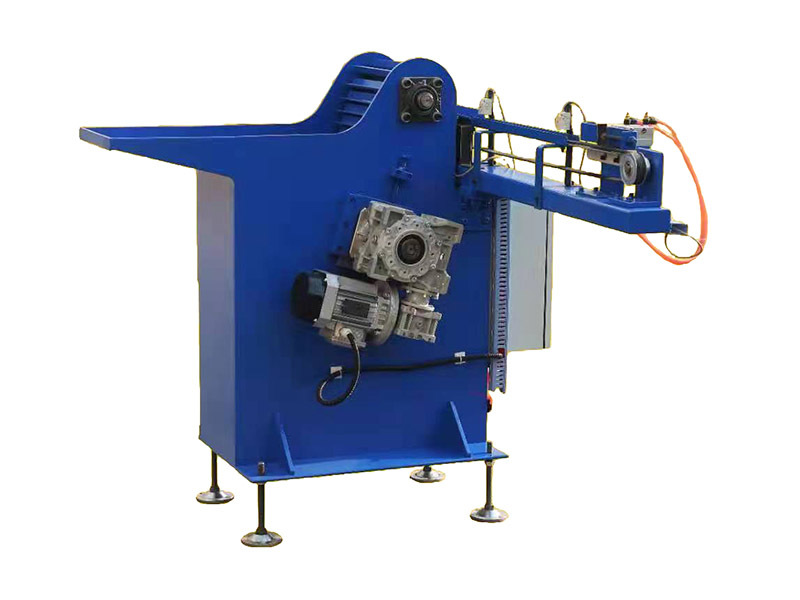

In the fast-paced world of manufacturing, efficiency is paramount. Automatic U Bolt Bending Machines are designed to meet this demand by providing high-speed, precise bending capabilities that streamline production processes. This advanced equipment not only enhances output but also minimizes waste and operational costs.

In this article, we will delve into the numerous benefits of utilizing an Automatic U Bolt Bending Machine, explore its key features, and guide you in making an informed purchase decision.

What is U Bolt Bending?

U bolt bending refers to the process of forming metal rods into a U-shaped configuration. This shape is crucial in a variety of applications, particularly in the automotive and construction industries, where U bolts are used to secure components together. The bending process involves applying precise forces to metal rods to create accurate bends without compromising material integrity.

The Importance of U Bolts in Manufacturing

U bolts serve as essential connectors in many applications, from suspending pipes to maintaining structural integrity in vehicles. Their reliability and strength make them indispensable in manufacturing. As industries demand higher quality and efficiency, the need for precise U bolt bending becomes increasingly critical.

Benefits of Using Automatic U Bolt Bending Machines

Adopting an Automatic U Bolt Bending Machine can significantly transform your manufacturing operations. Let's break down the core benefits:

Enhanced Precision and Consistency

Automatic U Bolt Bending Machines utilize advanced technology to achieve unparalleled accuracy in bending. The automated processes minimize human error, ensuring that each U bolt is consistently formed to exact specifications. This precision is crucial for maintaining the integrity and functionality of products, ultimately leading to higher customer satisfaction.

Increased Efficiency and Speed

One of the standout advantages of using an Automatic U Bolt Bending Machine is its speed. Traditional bending methods can be time-consuming and labor-intensive. In contrast, automatic machines can bend multiple U bolts in a fraction of the time, significantly increasing production capacity. This efficiency not only accelerates output but also allows manufacturers to meet tight deadlines more effectively.

Cost-Effectiveness and Reduced Labor Costs

Investing in an Automatic U Bolt Bending Machine may seem like a significant upfront cost; however, the long-term savings are substantial. By automating the bending process, manufacturers can reduce labor costs, as fewer personnel are required to operate the machinery. Additionally, the reduction in waste due to precise bending leads to lower material costs, further enhancing overall profitability.

Space-Saving Design and Automation

Many modern Automatic U Bolt Bending Machines are designed with compactness in mind. This space-saving design is ideal for facilities with limited floor space. Moreover, automation reduces the need for extensive manual setups and adjustments, allowing for a smoother workflow. Operators can focus on monitoring the process rather than performing repetitive tasks.

Key Features of Automatic U Bolt Bending Machines

To understand the full potential of Automatic U Bolt Bending Machines, it's essential to explore their key features:

Advanced Control Systems

Most automatic machines are equipped with intuitive control systems that allow for easy programming and operation. Operators can input specific bending parameters, ensuring that each U bolt is produced according to the required specifications.

Multiple Bending Options

Many machines offer various bending modes, accommodating different U bolt sizes and shapes. This versatility is crucial for manufacturers dealing with diverse product lines.

Durable Construction

Automatic U Bolt Bending Machines are built to withstand the rigors of continuous operation. High-quality materials and construction ensure longevity and reliability, reducing downtime and maintenance costs.

Safety Features

Modern machines come equipped with safety features to protect operators and the machine itself. Emergency stop buttons, protective enclosures, and sensors are standard to ensure a safe working environment.

How to Choose the Right U Bolt Bending Machine

Selecting the proper Automatic U Bolt Bending Machine involves considering several factors:

Production Volume

Assess your production needs. Higher volumes may require more advanced machines with faster bending capabilities.

Material Type

Ensure the machine can handle the material types you work with, whether steel, aluminum, or other metals.

Budget

While it’s essential to find a machine that fits your budget, consider the long-term ROI. Cheaper models may save money upfront but could lead to higher operating costs.

Case Studies: Success Stories with Automatic U Bolt Bending Machines

Numerous manufacturers have successfully integrated Automatic U Bolt Bending Machines into their operations, leading to remarkable improvements. For instance, a mid-sized automotive parts manufacturer reported a **30% increase in productivity** within the first month of implementation. By transitioning from manual to automated processes, they reduced labor costs significantly while improving product quality.

Another example includes a construction firm that faced delays due to inefficient U bolt production. After investing in an automatic machine, they were able to **cut production time by 40%**, enabling them to meet project deadlines without compromising quality.

The Future of U Bolt Bending Technology

As technology continues to evolve, the future of U bolt bending looks promising. Innovations such as AI-driven automation, smart sensors, and predictive maintenance are on the horizon. These advancements will further enhance the efficiency, accuracy, and adaptability of U bolt bending machines, making them indispensable in modern manufacturing.

Conclusion: Embracing the Future of U Bolt Bending

In conclusion, the integration of an Automatic U Bolt Bending Machine into manufacturing processes can yield significant benefits such as enhanced precision, increased efficiency, cost savings, and improved safety. By embracing this technology, manufacturers can position themselves for success in an increasingly competitive landscape. Investing in an automatic bending machine is not just a choice; it's a strategic decision that can unlock new levels of efficiency and profitability.

FAQs

1. What materials can be processed with an Automatic U Bolt Bending Machine?

Most machines can handle a variety of materials, including steel, aluminum, and other metals. Always check the specifications for the best results.

2. How much does an Automatic U Bolt Bending Machine cost?

The price varies depending on the machine's features, capacity, and brand. Generally, expect to invest anywhere from a few thousand to tens of thousands of dollars.

3. How does automation improve safety in bending operations?

Automation reduces the need for manual handling, which minimizes the risk of workplace accidents. Machines are equipped with safety features that protect operators and enhance safe working environments.

4. Can I customize bending specifications for different U bolt sizes?

Yes, most modern Automatic U Bolt Bending Machines allow for programmable settings, enabling customization for various sizes and shapes.

5. What maintenance is required for an Automatic U Bolt Bending Machine?

Regular maintenance includes cleaning, lubrication, and checking for wear and tear on parts. It's advisable to follow the manufacturer's guidelines for optimal performance.

By harnessing the power of an Automatic U Bolt Bending Machine, manufacturers can significantly improve their processes, leading to enhanced productivity and profitability.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us