Understanding Bolt Cold Forging Machines: An Essential Tool in Manufacturing

Summary:

Bolt Cold Forging Machines are specialized pieces of equipment that play a crucial role in the manufacturing and processing of various types of fasteners, particularly bolts. The cold forging process is characterized by the deformation of metal at room temperature, which results in enhanced properties of the final products. Unlike traditional machining processes, cold forging is more efficient and

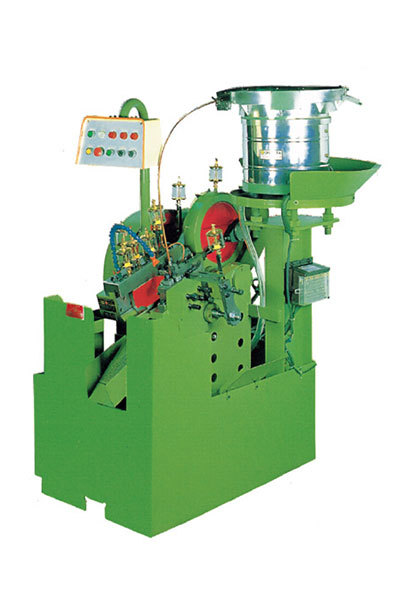

Bolt Cold Forging Machines are specialized pieces of equipment that play a crucial role in the manufacturing and processing of various types of fasteners, particularly bolts. The cold forging process is characterized by the deformation of metal at room temperature, which results in enhanced properties of the final products. Unlike traditional machining processes, cold forging is more efficient and environmentally friendly, offering numerous advantages that can significantly impact production.

The primary advantage of Bolt Cold Forging Machines is their ability to produce high precision components with improved mechanical properties. As the metal is shaped at lower temperatures, it retains its strength and structural integrity, which is essential for applications requiring high performance and reliability. Furthermore, cold forging minimizes waste material, as the process often requires less raw material compared to casting or machining.

One of the key applications of Bolt Cold Forging Machines is in the automotive industry, where high-strength bolts are essential for assembly. These machines allow manufacturers to produce complex shapes and designs, accommodating various specifications and sizes needed in automotive assembly lines. Additionally, cold forging is commonly used in the aerospace, construction, and electronics industries for producing durable and lightweight components.

Operating a Bolt Cold Forging Machine involves several steps, beginning with the selection of raw materials, typically steel or aluminum, which are fed into the machine. The forging process involves the use of dies that shape the metal under high pressure, creating the desired bolt configuration. The precision of the dies and the quality of the raw materials are critical factors in ensuring the final product meets industry standards.

Moreover, the efficiency of Bolt Cold Forging Machines can lead to significant cost savings for manufacturers. The rapid production cycles and reduction in material waste not only enhance productivity but also lower the overall manufacturing costs. As industries continue to prioritize sustainability and efficiency, the adoption of cold forging technologies is likely to grow.

In summary, Bolt Cold Forging Machines serve as a vital asset in modern manufacturing. Their ability to produce high-quality, precise components while minimizing waste aligns perfectly with the industry's push towards more sustainable practices. Understanding the operational principles and advantages of these machines can empower professionals in the manufacturing sector to make informed decisions that enhance productivity and product quality. As the market for fasteners continues to expand, the relevance of Bolt Cold Forging Machines will only increase, making it essential for industry professionals to stay informed and adaptable.

The primary advantage of Bolt Cold Forging Machines is their ability to produce high precision components with improved mechanical properties. As the metal is shaped at lower temperatures, it retains its strength and structural integrity, which is essential for applications requiring high performance and reliability. Furthermore, cold forging minimizes waste material, as the process often requires less raw material compared to casting or machining.

One of the key applications of Bolt Cold Forging Machines is in the automotive industry, where high-strength bolts are essential for assembly. These machines allow manufacturers to produce complex shapes and designs, accommodating various specifications and sizes needed in automotive assembly lines. Additionally, cold forging is commonly used in the aerospace, construction, and electronics industries for producing durable and lightweight components.

Operating a Bolt Cold Forging Machine involves several steps, beginning with the selection of raw materials, typically steel or aluminum, which are fed into the machine. The forging process involves the use of dies that shape the metal under high pressure, creating the desired bolt configuration. The precision of the dies and the quality of the raw materials are critical factors in ensuring the final product meets industry standards.

Moreover, the efficiency of Bolt Cold Forging Machines can lead to significant cost savings for manufacturers. The rapid production cycles and reduction in material waste not only enhance productivity but also lower the overall manufacturing costs. As industries continue to prioritize sustainability and efficiency, the adoption of cold forging technologies is likely to grow.

In summary, Bolt Cold Forging Machines serve as a vital asset in modern manufacturing. Their ability to produce high-quality, precise components while minimizing waste aligns perfectly with the industry's push towards more sustainable practices. Understanding the operational principles and advantages of these machines can empower professionals in the manufacturing sector to make informed decisions that enhance productivity and product quality. As the market for fasteners continues to expand, the relevance of Bolt Cold Forging Machines will only increase, making it essential for industry professionals to stay informed and adaptable.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us