Why Choose an Inverted Wire Drawing Machine for Your Metal Processing Needs?

Summary:

Introduction to Inverted Wire Drawing Machines

In the realm of metal processing, the tools and technologies you choose significantly impact your production efficiency and product quality. Among the various equipment available, the **inverted wire drawing machine** stands out for its unique design and operational advantages. This machine is essential for businesses aiming to optimize their metalwor

Introduction to Inverted Wire Drawing Machines

In the realm of metal processing, the tools and technologies you choose significantly impact your production efficiency and product quality. Among the various equipment available, the **inverted wire drawing machine** stands out for its unique design and operational advantages. This machine is essential for businesses aiming to optimize their metalworking processes, ensuring high-quality output with minimal waste.

Understanding Wire Drawing Technology

Wire drawing involves reducing the diameter of a wire by pulling it through a series of dies. The traditional process has its limitations, often resulting in increased material stress and energy consumption. However, the **inverted wire drawing machine** revolutionizes this process by introducing a different mechanism that enhances performance metrics.

How Do Inverted Wire Drawing Machines Work?

The inverted wire drawing machine operates through a series of steps that streamline wire production:

1. **Feeding the Wire**: The raw wire is fed into the machine, where it is prepared for the drawing process.

2. **Drawing Process**: Utilizing a unique inverted mechanism, the machine pulls the wire through a die, reducing its diameter while maintaining its structural integrity.

3. **Cooling and Lubrication**: Inverted wire drawing machines often incorporate advanced cooling and lubrication systems that help minimize friction and heat, enhancing the lifespan of both the wire and the machine.

4. **Final Output**: The finished wire is then spooled for further processing or immediate use.

This process not only improves productivity but also ensures consistent quality throughout the production run.

Key Benefits of Inverted Wire Drawing Machines

Investing in an inverted wire drawing machine offers numerous advantages that can transform your metal processing operations.

1. Enhanced Efficiency

One of the primary benefits of using an inverted wire drawing machine is its enhanced efficiency. The inverted design allows for smoother wire flow, reducing the energy required for drawing operations. This translates to shorter production times and lower operational costs.

2. Superior Quality of Wire Products

The careful design of inverted wire drawing machines ensures that the resulting wire has a uniform diameter and fewer defects. This improved quality is crucial for applications where precision is essential, such as in electrical wiring or mechanical components.

Maintaining Material Integrity

Inverted machines exert less stress on the wire during processing. This reduced stress helps maintain the material's integrity, ensuring that it meets the necessary strength and flexibility requirements.

3. Versatility in Applications

Inverted wire drawing machines are versatile and can draw various materials, including copper, aluminum, and steel. This adaptability makes them suitable for various industries, from construction to electronics.

4. Cost-Effectiveness

While the initial investment in an inverted wire drawing machine may be higher than traditional models, the long-term savings outweigh these costs. The increased efficiency, reduced material waste, and improved product quality lead to lower overall production costs.

Lower Maintenance Costs

The advanced technology used in these machines often results in lower maintenance needs, further enhancing their cost-effectiveness.

Choosing the Right Inverted Wire Drawing Machine

When selecting an inverted wire drawing machine, consider the following factors to ensure you choose the best model for your needs.

1. Production Capacity

Assess your production needs regarding volume and speed. Different machines come with various capacities, so choose one that aligns with your operational requirements.

2. Material Compatibility

Ensure that the machine is compatible with the materials you plan to process. Some machines are designed specifically for certain metals, while others offer broader versatility.

3. Technological Features

Look for machines equipped with advanced features such as programmable controls, integrated cooling systems, and automated lubrication. These enhancements can significantly improve efficiency and ease of operation.

4. Manufacturer Reputation

Research the manufacturer’s reputation in the industry. A reliable manufacturer will provide support, maintenance services, and warranty options that can enhance your investment.

Installation and Calibration of Inverted Wire Drawing Machines

Proper installation and calibration are essential for maximizing the performance of your inverted wire drawing machine.

1. Site Preparation

Before installation, ensure that your workspace is adequately prepared. This includes having sufficient space, power supply, and ventilation for optimal machine operation.

2. Professional Installation

Consider hiring professionals for installation to ensure that the machine is set up correctly. Incorrect installation can lead to operational inefficiencies and increased wear and tear.

3. Initial Calibration

After installation, perform an initial calibration to ensure that the machine operates within the desired parameters. This step is crucial for maintaining product quality and machine longevity.

Maintenance Best Practices for Inverted Wire Drawing Machines

Regular maintenance is key to ensuring the longevity and efficiency of your inverted wire drawing machine.

1. Routine Inspections

Conduct routine inspections to identify any potential issues before they escalate. Look for signs of wear and tear, loose components, or lubrication needs.

2. Lubrication and Cooling System Checks

Regularly check and maintain lubrication and cooling systems to ensure optimal performance. This practice helps reduce friction and heat, extending the machine's lifespan.

3. Cleaning and Debris Removal

Keep the machine clean and free from debris that can affect performance. Regular cleaning routines prevent buildup and promote smoother operation.

Case Studies: Successful Implementations of Inverted Wire Drawing Machines

Many companies have successfully integrated inverted wire drawing machines into their operations, achieving remarkable results.

1. Case Study: Electrical Component Manufacturer

An electrical component manufacturer implemented an inverted wire drawing machine and reported a **30% increase** in production efficiency. The consistent quality of wire produced also reduced returns and complaints from customers.

2. Case Study: Automotive Parts Supplier

A leading automotive parts supplier utilized an inverted wire drawing machine to draw high-strength steel wire. They experienced a **20% reduction** in material waste and an increase in product quality, leading to improved contracts with major automotive brands.

Conclusion

Choosing an inverted wire drawing machine for your metal processing needs is a strategic decision that can significantly enhance your production efficiency, product quality, and overall operational costs. With its unique design, versatility, and superior performance metrics, this machine is an invaluable asset in the metalworking industry. By investing in the right equipment and adhering to maintenance best practices, businesses can achieve remarkable results and gain a competitive edge in the market.

FAQs

1. What types of materials can be processed with an inverted wire drawing machine?

An inverted wire drawing machine is versatile and can process various materials, including copper, aluminum, and steel.

2. How does an inverted wire drawing machine differ from traditional machines?

The key difference lies in the inverted design, which allows for smoother wire flow and reduced stress during the drawing process, leading to better quality and efficiency.

3. What maintenance practices are essential for inverted wire drawing machines?

Routine inspections, regular lubrication, and maintaining cooling systems are crucial for ensuring optimal performance and longevity.

4. Can inverted wire drawing machines improve production efficiency?

Yes, these machines enhance efficiency by reducing energy consumption and production time, leading to lower operational costs.

5. What should I consider when selecting an inverted wire drawing machine?

Factors such as production capacity, material compatibility, technological features, and the manufacturer’s reputation are vital when making your selection.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

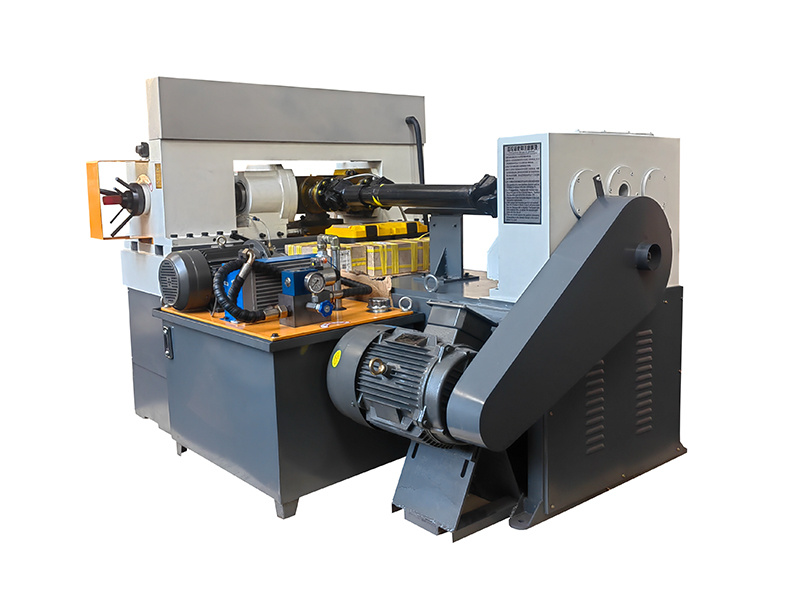

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us