Understanding Inverted Wire Drawing Machines: A Key Component in Metal Processing

Summary:

Inverted wire drawing machines are specialized devices used in the metal processing sector, primarily for the production of various wire types. These machines operate on the principle of reducing the diameter of metal rods or wires through a series of drawing dies. The "inverted" aspect refers to the design of these machines, which typically positions the drawing dies below the wire entry point, f

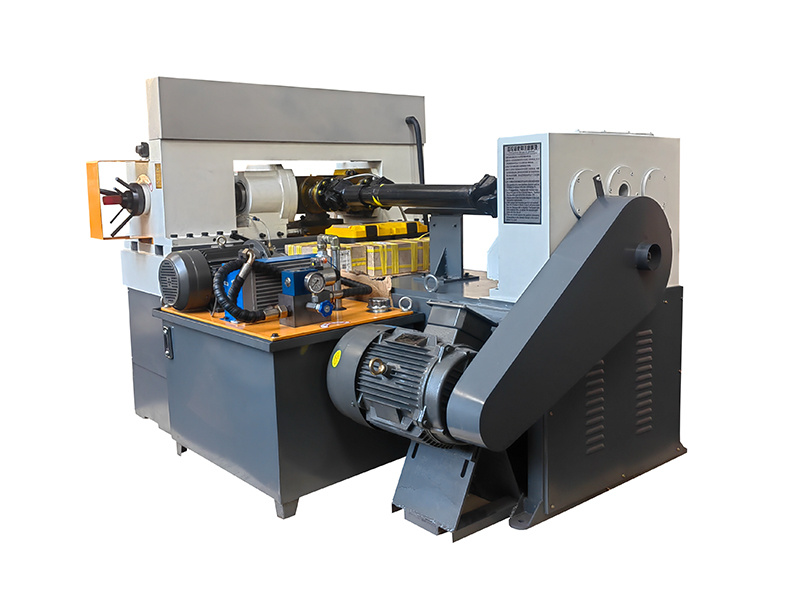

Inverted wire drawing machines are specialized devices used in the metal processing sector, primarily for the production of various wire types. These machines operate on the principle of reducing the diameter of metal rods or wires through a series of drawing dies. The "inverted" aspect refers to the design of these machines, which typically positions the drawing dies below the wire entry point, facilitating a more controlled and efficient wire drawing process.

One of the significant advantages of inverted wire drawing machines is their ability to enhance productivity. By allowing continuous operation, these machines minimize downtime and optimize production efficiency. They are particularly well-suited for high-volume manufacturing environments where consistent quality and speed are paramount. The inverted design also contributes to better tension control, which is crucial in maintaining the integrity of the wire during the drawing process.

The operational principles of inverted wire drawing machines primarily involve the use of multiple drawing dies. As the wire is pulled through each die, it experiences both tension and reduction in diameter. This sequential process enables manufacturers to achieve precise wire dimensions and surface finishes. Additionally, the ability to draw wire at various speeds and temperatures allows for tailored properties, catering to specific application needs.

Inverted wire drawing machines are employed across various industries, including construction, automotive, and electronics. For instance, in the automotive industry, these machines are essential for producing high-strength wires used in safety features and structural components. Similarly, in the electronics sector, they are used to manufacture fine wires for connectors and other critical components.

Furthermore, advancements in technology have led to the integration of automation and digital monitoring systems in inverted wire drawing machines. These innovations enhance precision and reduce the likelihood of human error, resulting in higher quality products and increased safety in manufacturing processes. Manufacturers can now monitor real-time data, making adjustments as needed to maintain optimal performance.

In conclusion, inverted wire drawing machines play a pivotal role in the metal processing industry, allowing for efficient, high-quality wire production. Their unique design and operational efficiency make them indispensable in various applications, from construction to electronics. Understanding the functionality and benefits of these machines can provide valuable insights for any business involved in metal fabrication. As technology continues to advance, the capabilities of inverted wire drawing machines will likely expand, further solidifying their importance in the manufacturing landscape.

One of the significant advantages of inverted wire drawing machines is their ability to enhance productivity. By allowing continuous operation, these machines minimize downtime and optimize production efficiency. They are particularly well-suited for high-volume manufacturing environments where consistent quality and speed are paramount. The inverted design also contributes to better tension control, which is crucial in maintaining the integrity of the wire during the drawing process.

The operational principles of inverted wire drawing machines primarily involve the use of multiple drawing dies. As the wire is pulled through each die, it experiences both tension and reduction in diameter. This sequential process enables manufacturers to achieve precise wire dimensions and surface finishes. Additionally, the ability to draw wire at various speeds and temperatures allows for tailored properties, catering to specific application needs.

Inverted wire drawing machines are employed across various industries, including construction, automotive, and electronics. For instance, in the automotive industry, these machines are essential for producing high-strength wires used in safety features and structural components. Similarly, in the electronics sector, they are used to manufacture fine wires for connectors and other critical components.

Furthermore, advancements in technology have led to the integration of automation and digital monitoring systems in inverted wire drawing machines. These innovations enhance precision and reduce the likelihood of human error, resulting in higher quality products and increased safety in manufacturing processes. Manufacturers can now monitor real-time data, making adjustments as needed to maintain optimal performance.

In conclusion, inverted wire drawing machines play a pivotal role in the metal processing industry, allowing for efficient, high-quality wire production. Their unique design and operational efficiency make them indispensable in various applications, from construction to electronics. Understanding the functionality and benefits of these machines can provide valuable insights for any business involved in metal fabrication. As technology continues to advance, the capabilities of inverted wire drawing machines will likely expand, further solidifying their importance in the manufacturing landscape.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us