The Benefits of Using an Inverted Wire Drawing Machine in Manufacturing

Summary:

The Benefits of Using an Inverted Wire Drawing Machine in Manufacturing

Introduction to Inverted Wire Drawing Machines

In the world of manufacturing, efficiency and precision are paramount. Inverted wire drawing machines have emerged as a game-changing technology in the metal processing sector, particularly for industries that rely on metal wire production. These machines offer various benefits th

The Benefits of Using an Inverted Wire Drawing Machine in Manufacturing

Introduction to Inverted Wire Drawing Machines

In the world of manufacturing, efficiency and precision are paramount. Inverted wire drawing machines have emerged as a game-changing technology in the metal processing sector, particularly for industries that rely on metal wire production. These machines offer various benefits that can significantly enhance manufacturing processes and outcomes. Let's delve deeper into what inverted wire drawing machines are and explore their advantages in the manufacturing landscape.

Understanding Inverted Wire Drawing Machines

What Is an Inverted Wire Drawing Machine?

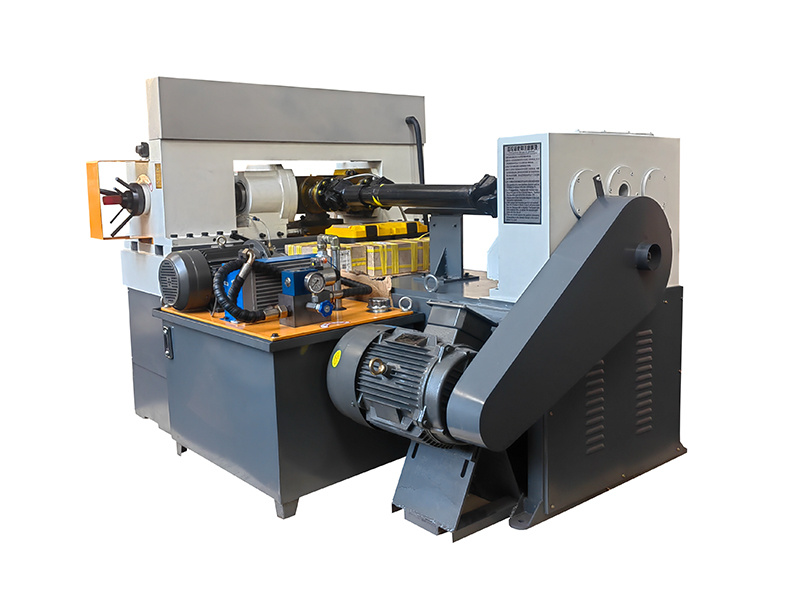

An inverted wire drawing machine is a specialized piece of equipment designed to draw metal wire through a series of dies, reducing its diameter while increasing its length. Unlike traditional wire drawing machines, the inverted design allows for more efficient material handling, improved operator safety, and enhanced production rates.

The Mechanics Behind Inverted Wire Drawing

The operation of an inverted wire drawing machine involves the following key components:

1. **Payoff System**: This system unwinds the metal wire from a coil, feeding it into the drawing chamber.

2. **Drawing Dies**: These are precision-engineered tools that reduce the diameter of the wire as it passes through them.

3. **Take-up System**: Once the wire is drawn to the desired thickness, it is wound onto a spool or coil.

The inverted design optimizes the flow of materials and minimizes the risk of tangling or damage during the drawing process.

The Advantages of Using Inverted Wire Drawing Machines

1. Enhanced Efficiency and Productivity

One of the standout benefits of inverted wire drawing machines is their ability to enhance efficiency and productivity significantly. The inverted design allows for smoother operation and quicker throughput. With less downtime for setups and adjustments, manufacturers can achieve higher output levels, making it an ideal choice for large-scale production runs.

2. Cost-Effectiveness in Manufacturing

Investing in inverted wire drawing machines can lead to substantial cost savings for manufacturers. The efficiency gains translate to lower labor costs and reduced material wastage. Additionally, the high-speed operation minimizes energy consumption, further decreasing production costs.

3. Improved Wire Quality and Consistency

Quality is a crucial factor in metal wire manufacturing. The precision engineering of inverted wire drawing machines ensures that the wire produced meets stringent industry standards. The controlled drawing process leads to consistent wire dimensions and improved surface finish, which is essential for applications like electrical wiring, construction, and automotive parts.

4. Enhanced Safety Features

Safety is a top priority in any manufacturing environment. Inverted wire drawing machines are designed with several safety features to protect operators and minimize the risk of accidents. These include automatic shut-off systems, protective guards around moving parts, and ergonomic designs that reduce strain on workers.

5. Versatility in Applications

Inverted wire drawing machines are incredibly versatile. They can be used to draw a wide variety of metals, including copper, aluminum, and steel. This adaptability makes them suitable for different manufacturing applications, from producing fine wire for electronics to heavy-duty cables for construction projects.

Key Considerations When Choosing an Inverted Wire Drawing Machine

1. Capacity and Size

When selecting an inverted wire drawing machine, manufacturers must consider the capacity and size that align with their production needs. Machines come in various sizes to accommodate different wire formulations and output requirements.

2. Automation Levels

The level of automation in a wire drawing machine can significantly impact productivity. Fully automated systems reduce the need for manual intervention, leading to increased output and decreased labor costs. However, semi-automated machines may still provide sufficient efficiency for smaller operations.

3. Maintenance Requirements

Maintenance is vital for ensuring the longevity and performance of machine tools. Manufacturers should assess the maintenance requirements of inverted wire drawing machines, looking for features that simplify upkeep while minimizing downtime.

4. Supplier Reputation

Choosing a reputable supplier for your inverted wire drawing machine is crucial. Research potential suppliers, read customer reviews, and consider their support and warranty offerings to ensure you're making a wise investment.

Real-World Applications of Inverted Wire Drawing Machines

1. Aerospace Industry

The aerospace sector demands high-quality wire for various applications, from aircraft wiring to component manufacturing. Inverted wire drawing machines can produce lightweight and durable wires that meet the industry's stringent safety and performance standards.

2. Automotive Manufacturing

In the automotive industry, wire is used in numerous applications, including electrical systems, structural components, and safety features. The consistent quality achieved through inverted wire drawing is essential for reliability in vehicles.

3. Electronics Production

The electronics industry requires fine wire for circuit boards and connections. Inverted wire drawing machines excel at producing thin, high-quality wires necessary for modern electronic devices, ensuring optimal performance and longevity.

Environmental Impact and Sustainability

1. Reduced Material Waste

Incorporating inverted wire drawing machines into manufacturing processes can minimize material waste. These machines ensure precise wire dimensions, reducing excess material usage and contributing to a more sustainable manufacturing footprint.

2. Energy Efficiency

Modern inverted wire drawing machines are designed for energy efficiency. By optimizing the drawing process and reducing power consumption, manufacturers can lower their overall energy footprint and foster a more sustainable production environment.

Frequently Asked Questions (FAQs)

1. What materials can be processed using an inverted wire drawing machine?

Inverted wire drawing machines can process various metals, including copper, aluminum, and steel, making them suitable for multiple applications across industries.

2. How does an inverted wire drawing machine improve safety in manufacturing?

These machines feature protective guards, automatic shut-off systems, and ergonomic designs, all contributing to a safer working environment for operators.

3. What factors should be considered when selecting an inverted wire drawing machine?

Consider capacity, automation level, maintenance needs, and supplier reputation when selecting an inverted wire drawing machine to ensure it aligns with your production requirements.

4. How do inverted wire drawing machines contribute to cost savings?

Inverted wire drawing machines enhance efficiency, reduce material waste, and lower energy consumption, leading to significant cost savings for manufacturers.

5. Can inverted wire drawing machines be used for small-scale production?

Yes, inverted wire drawing machines can be tailored to accommodate small-scale production, providing versatile solutions for manufacturers of all sizes.

Conclusion

Inverted wire drawing machines stand out as a revolutionary technology in the manufacturing sector, offering numerous benefits that can dramatically improve productivity, safety, and product quality. By investing in these machines, manufacturers can enhance their operational efficiency, reduce costs, and produce high-quality wire for various applications. As industries continue to evolve, incorporating advanced technologies like inverted wire drawing machines will be crucial for maintaining a competitive edge in an increasingly demanding marketplace.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us