Understanding Inverted Wire Drawing Machines: Innovations in Metal Processing

Summary:

Inverted wire drawing machines play a crucial role in the metal processing industry, particularly in the production of high-quality wire products. These machines are designed to draw metal wire through a die, reducing its diameter while increasing its length. The "inverted" design refers to the machine's configuration, where the wire is drawn downward through the die, as opposed to traditional hor

Inverted wire drawing machines play a crucial role in the metal processing industry, particularly in the production of high-quality wire products. These machines are designed to draw metal wire through a die, reducing its diameter while increasing its length. The "inverted" design refers to the machine's configuration, where the wire is drawn downward through the die, as opposed to traditional horizontal wire drawing setups.

One of the primary advantages of inverted wire drawing machines is their ability to enhance production efficiency. The vertical orientation allows for a more streamlined process, minimizing the need for complex handling systems or additional equipment. This design not only saves space on the shop floor but also reduces the time required for wire handling, thus enabling faster turnaround times.

Another significant benefit is the improved quality of the finished product. The controlled drawing process ensures uniformity in wire diameter and mechanical properties. Inverted wire drawing machines are particularly adept at handling various metal types, including copper, aluminum, and steel, making them versatile tools for manufacturers. The precision offered by these machines guarantees that the wire produced meets strict quality standards, which is critical for applications in sectors such as automotive, construction, and electronics.

Moreover, inverted wire drawing machines often come equipped with advanced features such as automatic tension control and real-time monitoring systems. These technological advancements help operators maintain optimal conditions throughout the drawing process, leading to fewer defects and higher yields. Additionally, many modern machines are designed with energy efficiency in mind, reducing operational costs and environmental impact.

The adaptability of inverted wire drawing machines also extends to their ability to accommodate various wire diameters and material specifications. This flexibility is essential in a competitive market where manufacturers must respond quickly to changing demands. With the capability to easily switch between different products, businesses can optimize their production lines and better serve diverse customer needs.

In summary, inverted wire drawing machines represent a significant advancement in the manufacturing and processing of metal wire. Their innovative design offers numerous advantages, including improved efficiency, superior product quality, and operational flexibility. As the metal processing industry continues to evolve, investing in advanced technologies like inverted wire drawing machines will be vital for maintaining competitiveness and meeting the demands of the market. Understanding these machines and their capabilities will empower professionals to make informed decisions in their operations, ultimately leading to enhanced productivity and profitability.

One of the primary advantages of inverted wire drawing machines is their ability to enhance production efficiency. The vertical orientation allows for a more streamlined process, minimizing the need for complex handling systems or additional equipment. This design not only saves space on the shop floor but also reduces the time required for wire handling, thus enabling faster turnaround times.

Another significant benefit is the improved quality of the finished product. The controlled drawing process ensures uniformity in wire diameter and mechanical properties. Inverted wire drawing machines are particularly adept at handling various metal types, including copper, aluminum, and steel, making them versatile tools for manufacturers. The precision offered by these machines guarantees that the wire produced meets strict quality standards, which is critical for applications in sectors such as automotive, construction, and electronics.

Moreover, inverted wire drawing machines often come equipped with advanced features such as automatic tension control and real-time monitoring systems. These technological advancements help operators maintain optimal conditions throughout the drawing process, leading to fewer defects and higher yields. Additionally, many modern machines are designed with energy efficiency in mind, reducing operational costs and environmental impact.

The adaptability of inverted wire drawing machines also extends to their ability to accommodate various wire diameters and material specifications. This flexibility is essential in a competitive market where manufacturers must respond quickly to changing demands. With the capability to easily switch between different products, businesses can optimize their production lines and better serve diverse customer needs.

In summary, inverted wire drawing machines represent a significant advancement in the manufacturing and processing of metal wire. Their innovative design offers numerous advantages, including improved efficiency, superior product quality, and operational flexibility. As the metal processing industry continues to evolve, investing in advanced technologies like inverted wire drawing machines will be vital for maintaining competitiveness and meeting the demands of the market. Understanding these machines and their capabilities will empower professionals to make informed decisions in their operations, ultimately leading to enhanced productivity and profitability.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

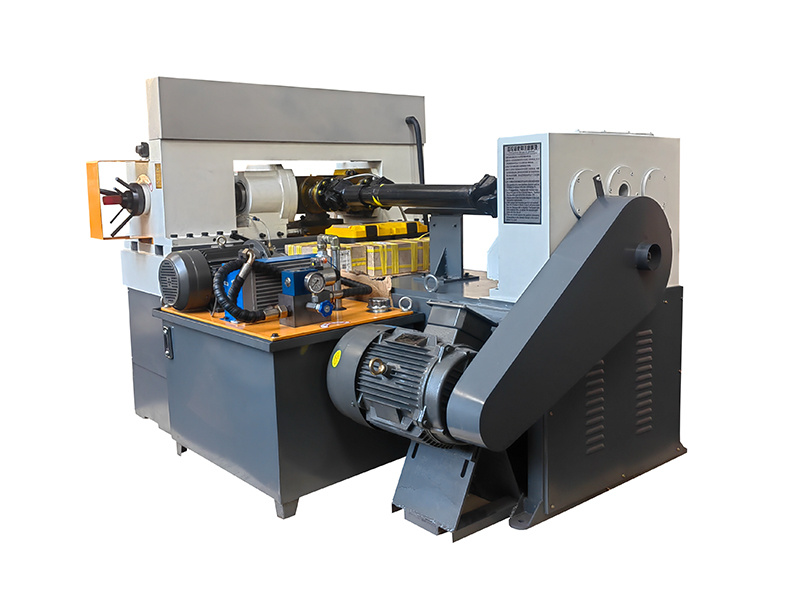

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us