The Ultimate Guide to Choosing the Right Double Head Chamfering Machine

Summary:

The Ultimate Guide to Choosing the Right Double Head Chamfering Machine

Table of Contents

1. Introduction to Double Head Chamfering Machines

2. Understanding the Chamfering Process

3. Importance of a Double Head Chamfering Machine

4. Key Features to Consider When Choosing a Double Head Chamfering Machine

5. Material Considerations for Chamfering

6. Types of Chamfering Machines

7. To

The Ultimate Guide to Choosing the Right Double Head Chamfering Machine

Table of Contents

- 1. Introduction to Double Head Chamfering Machines

- 2. Understanding the Chamfering Process

- 3. Importance of a Double Head Chamfering Machine

- 4. Key Features to Consider When Choosing a Double Head Chamfering Machine

- 5. Material Considerations for Chamfering

- 6. Types of Chamfering Machines

- 7. Top Brands and Models of Double Head Chamfering Machines

- 8. Maintenance and Care for Your Chamfering Machine

- 9. Conclusion

- 10. Frequently Asked Questions

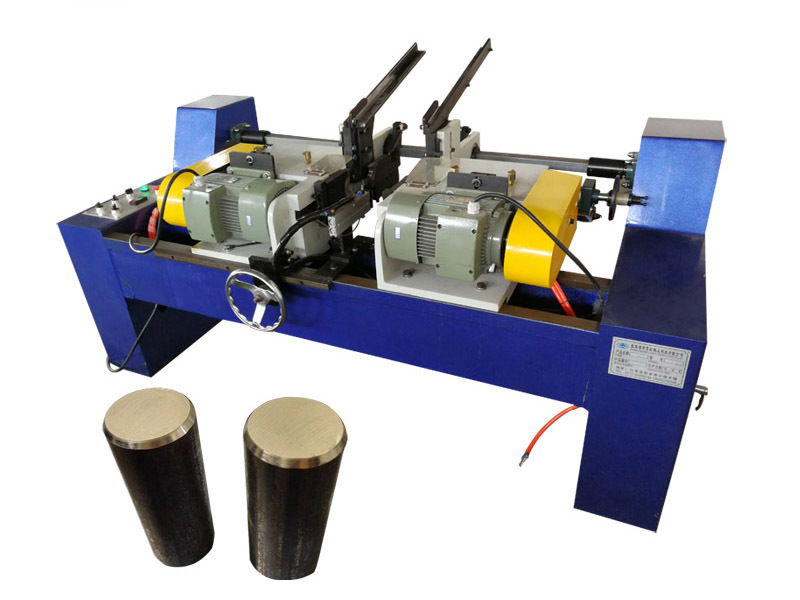

1. Introduction to Double Head Chamfering Machines

In the world of manufacturing, precision is paramount. A double head chamfering machine is an advanced tool designed to produce accurate bevels on various materials, enhancing both functionality and aesthetics. This guide walks you through the essentials of choosing the right double head chamfering machine, ensuring you make an informed investment for your business.

2. Understanding the Chamfering Process

Chamfering is the process of beveling the edges of a workpiece to eliminate sharp corners. This technique is crucial in various industries, including metalworking, woodworking, and plastic machining. By chamfering edges, manufacturers can improve safety, assembly, and the overall appearance of products. The double head chamfering machine allows for simultaneous operations, increasing efficiency and output.

3. Importance of a Double Head Chamfering Machine

A double head chamfering machine offers several advantages over single head versions:

3.1 Increased Productivity

By working on two edges at once, a double head machine significantly reduces cycle time, allowing for higher production rates without compromising quality.

3.2 Enhanced Precision

These machines maintain tight tolerances, ensuring that the chamfered edges meet exact specifications, which is vital for parts that require precise fits.

3.3 Versatile Applications

A double head chamfering machine is adaptable for various applications, from creating bevels on metal sheets to machining plastic components. This versatility makes it an invaluable asset in a modern machining environment.

4. Key Features to Consider When Choosing a Double Head Chamfering Machine

When selecting a double head chamfering machine, several features should be evaluated:

4.1 Build Quality and Stability

The construction of the machine should be robust to withstand the rigors of high-volume production. A heavy-duty frame contributes to stability and accuracy.

4.2 Cutting Speed and Adjustability

Evaluate the machine’s cutting speed capabilities and whether it allows for adjustments. Different materials may require varying speeds for optimal results.

4.3 Tooling and Accessories

Consider the availability of compatible tools and accessories, as these will affect the machine's versatility and ease of use.

4.4 Programmability and Automation

Modern machines often come with programmable features, allowing for automated operations. This functionality enhances precision and reduces the likelihood of human error.

4.5 Safety Features

Safety should never be compromised. Look for features such as emergency stop buttons, safety guards, and sensors that help protect operators during use.

5. Material Considerations for Chamfering

Different materials respond uniquely to chamfering processes. Understanding these differences is vital for choosing the right tools and settings.

5.1 Metals

Metals such as aluminum, steel, and stainless steel have distinct properties that affect the chamfering process. Ensure that the machine can handle the specific metal types your operations involve.

5.2 Plastics

Plastics can melt or chip if not handled correctly. It’s crucial to select a machine that can be adjusted for lower speeds when chamfering plastic materials.

5.3 Composites

Composite materials often require specialized tooling. Ensure the machine can accommodate the unique characteristics of these advanced materials.

6. Types of Chamfering Machines

Several types of chamfering machines are available in the market, each suited for specific applications.

6.1 Manual Chamfering Machines

These are operated by hand and are suitable for small batches or one-off projects. They provide flexibility but require skilled operators.

6.2 Automatic Chamfering Machines

Designed for high-volume production, automatic machines streamline the chamfering process and significantly boost efficiency.

6.3 CNC Chamfering Machines

Computer numerical control (CNC) machines offer unparalleled precision and can handle complex designs. They are ideal for manufacturers seeking high accuracy and repeatability.

7. Top Brands and Models of Double Head Chamfering Machines

When it comes to investing in a double head chamfering machine, choosing a reputable brand is essential. Some of the top brands include:

7.1 XYZ Machine Tools

Known for robust construction and reliability, XYZ offers a range of double head machines suitable for various applications.

7.2 Haas Automation

Haas is a leader in CNC machining. Their double head chamfering machines are designed for precision and efficiency, making them a preferred choice for many manufacturers.

7.3 JET Tools

JET Tools provides well-engineered machines that combine performance with affordability. Their double head models deliver excellent results for both metal and plastic applications.

8. Maintenance and Care for Your Chamfering Machine

Proper maintenance is key to prolonging the lifespan of your double head chamfering machine.

8.1 Regular Cleaning

Keep the machine clean from metal shavings and debris to prevent malfunctions and maintain optimal performance.

8.2 Lubrication

Regularly lubricate moving parts according to the manufacturer’s guidelines to ensure smooth operation and prevent wear.

8.3 Periodic Inspections

Conduct routine inspections to identify and address any potential issues before they escalate into costly repairs.

9. Conclusion

Choosing the right double head chamfering machine can significantly impact your manufacturing efficiency and quality. By understanding the chamfering process, evaluating key features, and considering material compatibility, you can make informed choices that lead to enhanced production capabilities. The investment in a high-quality machine will pay off in increased productivity, precision, and ultimately, profitability in your operations.

10. Frequently Asked Questions

10.1 What is a double head chamfering machine?

A double head chamfering machine is a specialized tool designed to create bevels on two edges of a workpiece simultaneously, enhancing efficiency in manufacturing processes.

10.2 How do I choose the right chamfering machine for my needs?

Consider factors such as the materials you work with, the volume of production, required precision, and key features like automation and programming capabilities.

10.3 What materials can be chamfered with a double head machine?

Double head chamfering machines can work with a variety of materials, including metals, plastics, and composites, but specific settings and tools may be required for each type.

10.4 Are double head chamfering machines easy to operate?

While they can be complex, many modern machines come with user-friendly interfaces and programmable features that simplify operation for users.

10.5 What maintenance is required for a chamfering machine?

Routine maintenance includes regular cleaning, lubrication of moving parts, and periodic inspections to ensure optimal performance and longevity.

By following this comprehensive guide, manufacturers can confidently select the right double head chamfering machine that meets their unique operational needs and contributes to their success.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us