Maximize Efficiency with the Double Head Chamfering Machine: A Comprehensive Guide

Summary:

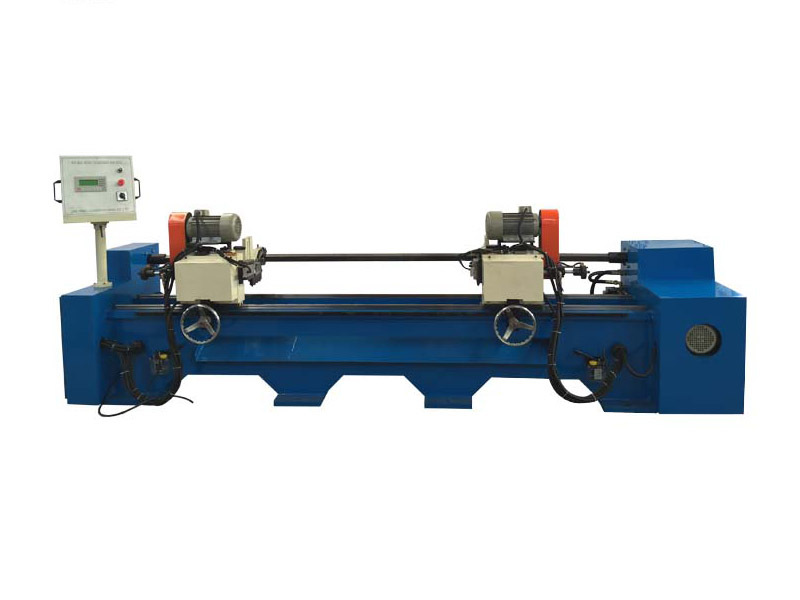

In the dynamic world of manufacturing, efficiency and precision are paramount. One tool that stands out for achieving these objectives is the Double Head Chamfering Machine. This versatile device is designed specifically for chamfering edges of metal, wood, and other materials, making it an essential asset for various industries, including automotive, aerospace, and construction.

A Double Head Cha

In the dynamic world of manufacturing, efficiency and precision are paramount. One tool that stands out for achieving these objectives is the Double Head Chamfering Machine. This versatile device is designed specifically for chamfering edges of metal, wood, and other materials, making it an essential asset for various industries, including automotive, aerospace, and construction.

A Double Head Chamfering Machine operates with two cutting heads, allowing for simultaneous processing of multiple edges or parts. This dual-head configuration not only speeds up production times but also ensures uniform quality in chamfering operations. The machine is capable of handling different materials, making it a flexible choice for manufacturers looking to streamline their operations.

One of the key advantages of using a Double Head Chamfering Machine is its ability to enhance the safety and finish of machined parts. Chamfering edges is critical as it removes sharp corners, reducing the risk of injury during handling and assembly. Additionally, a properly chamfered edge improves the overall aesthetic and functional quality of the finished product, contributing to better assembly fits and reduced wear on mating parts.

Moreover, these machines often come equipped with adjustable cutting speeds and angles, providing operators with the flexibility to customize their operations according to specific project requirements. The advanced design of a Double Head Chamfering Machine also typically includes features that minimize vibration and noise, allowing for a safer and quieter working environment.

Operating a Double Head Chamfering Machine does require some technical knowledge. It’s essential for operators to be trained in setup procedures, tool alignment, and maintenance to ensure optimal performance and longevity of the machine. Regular maintenance is crucial; keeping the cutting heads sharp and the machine clean will not only enhance its efficiency but also prolong its service life.

For those considering the integration of a Double Head Chamfering Machine into their production line, it's important to evaluate the specific needs of your operation. Factors such as the types of materials you'll be working with, the volume of production, and the required edge finishes should guide your choice.

In summary, a Double Head Chamfering Machine represents a significant advancement in the manufacturing process, significantly improving productivity while maintaining high-quality standards. By understanding its features and operational best practices, manufacturers can leverage this powerful tool to achieve greater efficiency and quality in their chamfering tasks.

A Double Head Chamfering Machine operates with two cutting heads, allowing for simultaneous processing of multiple edges or parts. This dual-head configuration not only speeds up production times but also ensures uniform quality in chamfering operations. The machine is capable of handling different materials, making it a flexible choice for manufacturers looking to streamline their operations.

One of the key advantages of using a Double Head Chamfering Machine is its ability to enhance the safety and finish of machined parts. Chamfering edges is critical as it removes sharp corners, reducing the risk of injury during handling and assembly. Additionally, a properly chamfered edge improves the overall aesthetic and functional quality of the finished product, contributing to better assembly fits and reduced wear on mating parts.

Moreover, these machines often come equipped with adjustable cutting speeds and angles, providing operators with the flexibility to customize their operations according to specific project requirements. The advanced design of a Double Head Chamfering Machine also typically includes features that minimize vibration and noise, allowing for a safer and quieter working environment.

Operating a Double Head Chamfering Machine does require some technical knowledge. It’s essential for operators to be trained in setup procedures, tool alignment, and maintenance to ensure optimal performance and longevity of the machine. Regular maintenance is crucial; keeping the cutting heads sharp and the machine clean will not only enhance its efficiency but also prolong its service life.

For those considering the integration of a Double Head Chamfering Machine into their production line, it's important to evaluate the specific needs of your operation. Factors such as the types of materials you'll be working with, the volume of production, and the required edge finishes should guide your choice.

In summary, a Double Head Chamfering Machine represents a significant advancement in the manufacturing process, significantly improving productivity while maintaining high-quality standards. By understanding its features and operational best practices, manufacturers can leverage this powerful tool to achieve greater efficiency and quality in their chamfering tasks.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us