Top Benefits of Using a Double Head Chamfering Machine in Metalworking

Summary:

Top Benefits of Using a Double Head Chamfering Machine in Metalworking

In the metalworking industry, efficiency and precision are paramount. One of the most significant advancements in this field is the introduction of the **double head chamfering machine**. This powerful tool brings several advantages that can revolutionize your manufacturing process. In this article, we will explore the top bene

Top Benefits of Using a Double Head Chamfering Machine in Metalworking

In the metalworking industry, efficiency and precision are paramount. One of the most significant advancements in this field is the introduction of the **double head chamfering machine**. This powerful tool brings several advantages that can revolutionize your manufacturing process. In this article, we will explore the top benefits of utilizing a double head chamfering machine in metalworking, how it enhances productivity, and why it is becoming a must-have for modern manufacturing facilities.

Table of Contents

- 1. Introduction to Chamfering Machines

- 2. What is a Double Head Chamfering Machine?

- 3. Key Benefits of Double Head Chamfering Machines

- 3.1 Improved Efficiency and Productivity

- 3.2 Enhanced Precision and Quality

- 3.3 Cost-Effectiveness

- 3.4 Versatility in Metalworking

- 3.5 Reduced Labor and Time

- 4. Applications of Double Head Chamfering Machines

- 5. Choosing the Right Double Head Chamfering Machine

- 6. Maintenance and Care

- 7. Conclusion

- 8. FAQs

1. Introduction to Chamfering Machines

Chamfering is a vital process in metalworking, used to create beveled edges on materials. This technique not only improves the aesthetic appeal of finished products but also enhances their functionality. Chamfering machines automate this process, providing precision and speed that manual methods cannot achieve. The advent of **double head chamfering machines** represents a significant leap forward in this technology.

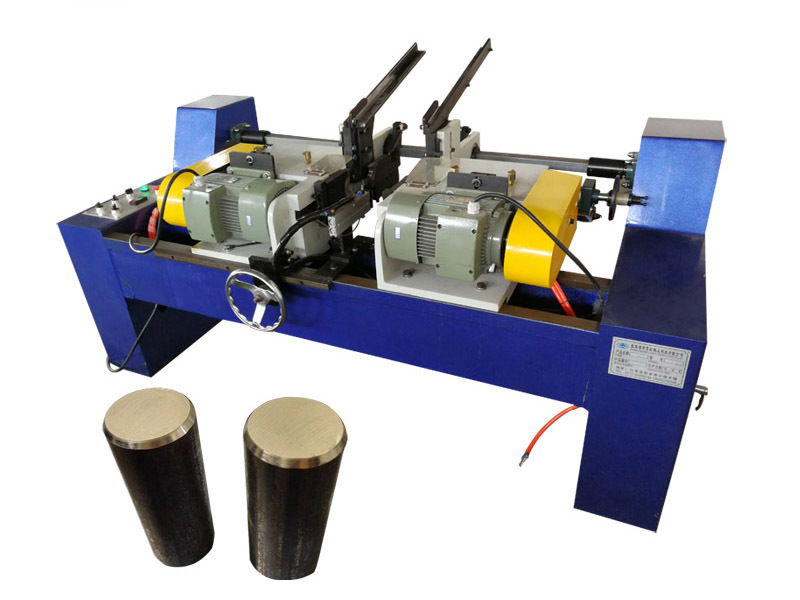

2. What is a Double Head Chamfering Machine?

A double head chamfering machine features two cutting heads that work simultaneously, enabling it to process two edges at once. This dual functionality drastically increases production speed without compromising quality. Typically equipped with advanced features such as adjustable cutting angles and speeds, double head chamfering machines are designed to handle a wide variety of materials, making them an invaluable asset for metalworking companies.

3. Key Benefits of Double Head Chamfering Machines

The advantages of **double head chamfering machines** are manifold. Below, we delve into each benefit in detail:

3.1 Improved Efficiency and Productivity

The primary advantage of a double head chamfering machine is its ability to significantly enhance efficiency and productivity. By processing two edges simultaneously, these machines can cut production time in half compared to single head machines. This efficiency allows manufacturers to meet tighter deadlines and increase order fulfillment rates, ultimately boosting overall productivity.

3.2 Enhanced Precision and Quality

Precision is critical in metalworking, where even the slightest deviation can lead to costly errors. Double head chamfering machines are engineered for accuracy, ensuring that every cut is consistent and precise. The ability to adjust cutting angles and depths further enhances the quality of the finished product. This level of precision results in fewer defective items and reduced waste, contributing to a more sustainable manufacturing process.

3.3 Cost-Effectiveness

Investing in a double head chamfering machine can lead to substantial cost savings over time. While the initial investment may be higher than that of a single head machine, the increased efficiency and reduced labor costs quickly offset this expense. Furthermore, the improved quality minimizes waste and rework, translating into further savings. Many manufacturers find that the long-term benefits far outweigh the initial costs, making it a wise investment.

3.4 Versatility in Metalworking

Double head chamfering machines are designed to handle a diverse range of materials, from aluminum to steel. This versatility means that manufacturers can use the same machine for various projects, accommodating different specifications without requiring multiple machines. Additionally, many models offer adjustable features, allowing operators to customize settings for specific tasks, enhancing their adaptability.

3.5 Reduced Labor and Time

Automation is a key advantage of double head chamfering machines. With the ability to perform tasks quickly and accurately, these machines reduce the need for manual labor, freeing up workers for more complex tasks that require human intervention. This reduction in labor not only lowers operational costs but also improves safety in the workplace, as fewer employees are required to handle potentially hazardous materials.

4. Applications of Double Head Chamfering Machines

Double head chamfering machines find applications across a broad spectrum of industries, including:

- **Automotive Manufacturing**: Used in the production of parts and components that require precise edges for assembly.

- **Aerospace Engineering**: Essential for creating lightweight, durable parts that meet stringent safety standards.

- **Construction**: Useful for fabricating metal components for buildings and infrastructure.

- **General Fabrication**: Ideal for various custom metalworking projects that require high precision and efficiency.

5. Choosing the Right Double Head Chamfering Machine

Selecting the appropriate double head chamfering machine involves considering several factors:

- **Material Compatibility**: Ensure the machine can handle the materials you work with most frequently.

- **Cutting Capacity**: Look for machines that meet your volume and size requirements.

- **Ease of Use**: Consider user-friendly controls and settings to minimize the training time.

- **Maintenance Requirements**: Choose models that are easy to maintain to ensure longevity and reliability.

By taking these factors into account, manufacturers can select a machine that best fits their specific needs.

6. Maintenance and Care

Proper maintenance is crucial for the longevity and efficiency of a double head chamfering machine. Regular checks and maintenance practices include:

- **Routine Cleaning**: Keep the machine clean from debris and metal shavings to prevent issues.

- **Lubrication**: Regularly oil moving parts to reduce friction and wear.

- **Inspection**: Periodically inspect cutting tools for signs of wear and replace them as necessary.

- **Calibration**: Ensure the machine is calibrated correctly to maintain precision.

By adhering to these maintenance practices, operators can maximize the machine's performance and lifespan.

7. Conclusion

The **double head chamfering machine** is a game-changer in the metalworking industry. Its ability to improve efficiency, enhance precision, and reduce costs makes it an indispensable tool for modern manufacturers. As companies strive to remain competitive and meet the ever-increasing demands of the market, integrating advanced machinery like the double head chamfering machine can lead to significant improvements in production capabilities. Investing in this technology not only streamlines operations but also positions businesses for future growth and success.

8. FAQs

What are the primary advantages of a double head chamfering machine?

The primary advantages include improved efficiency, enhanced precision, cost-effectiveness, versatility, and reduced labor requirements.

Can double head chamfering machines handle various materials?

Yes, they are designed to work with a range of materials, including aluminum, steel, and other metals.

How does a double head chamfering machine improve productivity?

By processing two edges simultaneously, these machines significantly cut production time compared to single head models.

What maintenance is required for a double head chamfering machine?

Regular cleaning, lubrication, inspection of cutting tools, and calibration are essential for maintaining machine performance.

Are double head chamfering machines easy to operate?

Many models are designed with user-friendly controls that simplify operation, minimizing the learning curve for new operators.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us