Enhancing Precision and Efficiency: The Double Head Chamfering Machine

Summary:

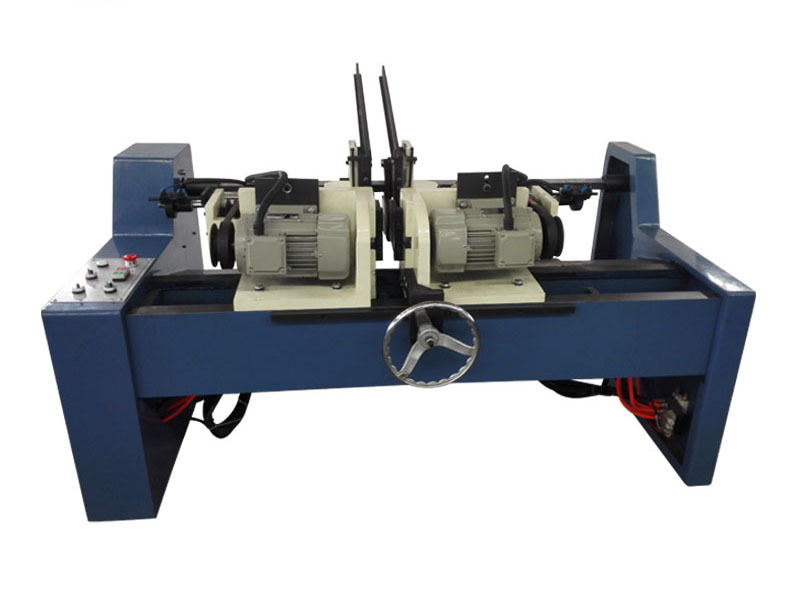

In the realm of manufacturing and machining, efficiency and precision are key factors that drive productivity and product quality. One of the tools that significantly contribute to these aspects is the double head chamfering machine. This specialized equipment is designed to bevel the edges of various materials, ensuring a clean finish and improving the overall integrity of components.

A double h

In the realm of manufacturing and machining, efficiency and precision are key factors that drive productivity and product quality. One of the tools that significantly contribute to these aspects is the double head chamfering machine. This specialized equipment is designed to bevel the edges of various materials, ensuring a clean finish and improving the overall integrity of components.

A double head chamfering machine stands out due to its dual-head setup, which allows for simultaneous processing of two edges. This feature dramatically increases throughput, making it an ideal choice for high-volume production environments. By reducing the time taken to chamfer edges, manufacturers can meet tight deadlines without compromising on quality.

One of the primary benefits of using a double head chamfering machine is its ability to produce consistent results. The precision engineering behind these machines ensures that each chamfer is uniform, which is crucial for applications that require tight tolerances. This consistency not only enhances the aesthetic appeal of the finished product but also improves its functionality, particularly in parts that need to fit together seamlessly.

Additionally, the versatility of the double head chamfering machine cannot be overstated. It can handle various materials, including metals, plastics, and composites, making it suitable for diverse industries such as automotive, aerospace, and construction. The ability to adapt to different materials means that manufacturers can streamline their operations and minimize the need for multiple machines.

Another aspect worth mentioning is the ease of operation typically associated with these machines. Modern double head chamfering machines come equipped with user-friendly controls and automation features, allowing operators to quickly set up, adjust, and monitor the processes. This ease of use reduces training time for new staff and enhances overall workplace safety, as operators can focus on maintaining quality rather than grappling with complex machinery.

Furthermore, many double head chamfering machines include features that enhance their functionality, such as adjustable cutting speeds and angles. This adaptability allows for a tailored approach to various chamfering tasks, enabling manufacturers to optimize their processes for specific projects.

In summary, the double head chamfering machine is a vital tool in the manufacturing sector, offering numerous benefits such as increased efficiency, precision, versatility, and user-friendly operation. By integrating this technology into production lines, companies can not only enhance their output but also improve the quality of their finished products, positioning themselves competitively in the market. As the demands of the industry evolve, investing in advanced tools like the double head chamfering machine will be essential for staying ahead.

A double head chamfering machine stands out due to its dual-head setup, which allows for simultaneous processing of two edges. This feature dramatically increases throughput, making it an ideal choice for high-volume production environments. By reducing the time taken to chamfer edges, manufacturers can meet tight deadlines without compromising on quality.

One of the primary benefits of using a double head chamfering machine is its ability to produce consistent results. The precision engineering behind these machines ensures that each chamfer is uniform, which is crucial for applications that require tight tolerances. This consistency not only enhances the aesthetic appeal of the finished product but also improves its functionality, particularly in parts that need to fit together seamlessly.

Additionally, the versatility of the double head chamfering machine cannot be overstated. It can handle various materials, including metals, plastics, and composites, making it suitable for diverse industries such as automotive, aerospace, and construction. The ability to adapt to different materials means that manufacturers can streamline their operations and minimize the need for multiple machines.

Another aspect worth mentioning is the ease of operation typically associated with these machines. Modern double head chamfering machines come equipped with user-friendly controls and automation features, allowing operators to quickly set up, adjust, and monitor the processes. This ease of use reduces training time for new staff and enhances overall workplace safety, as operators can focus on maintaining quality rather than grappling with complex machinery.

Furthermore, many double head chamfering machines include features that enhance their functionality, such as adjustable cutting speeds and angles. This adaptability allows for a tailored approach to various chamfering tasks, enabling manufacturers to optimize their processes for specific projects.

In summary, the double head chamfering machine is a vital tool in the manufacturing sector, offering numerous benefits such as increased efficiency, precision, versatility, and user-friendly operation. By integrating this technology into production lines, companies can not only enhance their output but also improve the quality of their finished products, positioning themselves competitively in the market. As the demands of the industry evolve, investing in advanced tools like the double head chamfering machine will be essential for staying ahead.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us