The Environmental Benefits of Bolt Cold Forging Machines: A Sustainable Manufacturing Revolution

Summary:

The Environmental Benefits of Bolt Cold Forging Machines

Introduction to Cold Forging Technology

Cold forging is a process that shapes materials at room temperature, which is notably different from traditional hot forging methods. As industries focus on sustainability, bolt cold forging machines have gained prominence due to their energy-efficient operations and reduced environmental impact. This

The Environmental Benefits of Bolt Cold Forging Machines

Introduction to Cold Forging Technology

Cold forging is a process that shapes materials at room temperature, which is notably different from traditional hot forging methods. As industries focus on sustainability, bolt cold forging machines have gained prominence due to their energy-efficient operations and reduced environmental impact. This article delves into the numerous environmental benefits provided by bolt cold forging machines, emphasizing their crucial role in modern manufacturing.

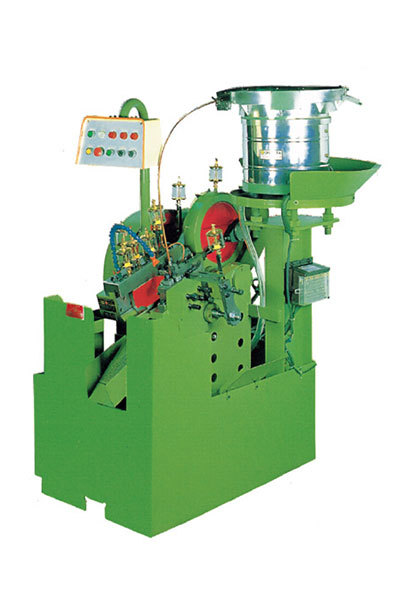

Understanding Bolt Cold Forging Machines

What is Bolt Cold Forging?

Bolt cold forging involves the deformation of metal at ambient temperatures to create bolts and other fasteners. By applying pressure to the metal, manufacturers can achieve the desired shape without the need for heating. This method results in a higher yield strength and improved surface finish, reducing the need for secondary machining.

Key Features of Bolt Cold Forging Machines

Bolt cold forging machines are equipped with advanced technology that enhances their functionality. Key features include:

- **High Precision:** The machines deliver consistent and precise dimensions, minimizing waste.

- **Energy Efficiency:** Reduced energy consumption compared to traditional forging methods.

- **Automated Processes:** Automation leads to fewer human errors and increased production rates.

The Environmental Advantages of Bolt Cold Forging Machines

1. Energy Efficiency and Reduced Carbon Footprint

One of the primary environmental benefits of bolt cold forging machines is their energy efficiency. Traditional forging processes often require significant energy input for heating metals. In contrast, cold forging eliminates the need for heat, leading to a substantial reduction in energy consumption. This not only lowers operational costs but also contributes to a decreased carbon footprint, making manufacturing processes more sustainable.

2. Minimal Waste Production

Cold forging processes generate less scrap metal compared to conventional methods. The high precision of bolt cold forging machines allows for near-net shape production, meaning that very little material is wasted during the manufacturing process. This efficiency not only conserves raw materials but also reduces the environmental impact associated with mining and processing metals.

Reducing Material Waste

By using advanced software and machinery, manufacturers can optimize the production process, ensuring that every piece of metal is utilized effectively. This reduction in waste contributes significantly to a more sustainable manufacturing environment.

3. Recyclability of Materials

Metals produced through cold forging are highly recyclable. Manufacturers can reclaim and recycle the scrap generated from the forging process, further minimizing environmental impact. This recycling capability ensures that materials are reused, promoting a circular economy within the manufacturing sector.

4. Lower Emissions and Pollution

Cold forging machines operate with fewer emissions than their hot forging counterparts. The absence of heating processes results in lower greenhouse gas emissions, contributing to a cleaner manufacturing environment. Additionally, the reduction of airborne pollutants associated with heating processes leads to improved air quality, benefiting both workers and surrounding communities.

Enhancing Sustainability Practices in Manufacturing

5. Sustainable Sourcing of Materials

Bolt cold forging machines often utilize high-quality, sustainably sourced materials. By choosing materials that have been obtained responsibly, manufacturers can further enhance their environmental profile. This practice not only supports eco-friendly initiatives but also encourages other industries to adopt similar sustainable sourcing strategies.

6. Continuous Improvement and Innovation

The industry is witnessing a continuous push towards innovation in bolt cold forging technology. Manufacturers are investing in research and development to further enhance the efficiency and sustainability of their processes. This commitment to innovation ensures that bolt cold forging machines will continue to evolve, providing even greater environmental benefits in the future.

Case Studies: Successful Implementation of Cold Forging Machines

7. Industry Leaders Embracing Cold Forging

Numerous companies across various industries have successfully integrated bolt cold forging machines into their operations. These case studies demonstrate the tangible environmental benefits achieved through the adoption of this technology.

Example 1: Automotive Industry

In the automotive sector, manufacturers have reported significant reductions in energy consumption and waste production after transitioning to cold forging processes for producing fasteners and components. This shift not only contributes to cost savings but also enhances the company's overall sustainability goals.

Example 2: Aerospace Industry

Aerospace manufacturers have also recognized the advantages of bolt cold forging. By utilizing this technology, they can produce lightweight components that meet stringent aerospace standards while minimizing their ecological footprint. The result is a more sustainable approach to manufacturing that aligns with industry regulations and environmental standards.

Frequently Asked Questions (FAQs)

1. What are the primary benefits of using bolt cold forging machines?

Bolt cold forging machines offer energy efficiency, reduced waste production, lower emissions, and the ability to produce high-quality metal components with minimal environmental impact.

2. How does cold forging compare to traditional forging methods?

Cold forging operates at room temperature, eliminating the need for heating, which results in reduced energy consumption and lower emissions compared to traditional hot forging methods.

3. Is the scrap generated during cold forging recyclable?

Yes, the scrap generated during bolt cold forging is highly recyclable, supporting sustainable practices within the manufacturing sector.

4. What industries benefit the most from bolt cold forging technology?

Industries such as automotive, aerospace, and construction benefit significantly from bolt cold forging technology due to its precision, energy efficiency, and reduced environmental impact.

5. How can manufacturers enhance their sustainability efforts using cold forging machines?

Manufacturers can enhance sustainability by investing in advanced technologies, optimizing processes, investing in sustainable sourcing of materials, and continuously innovating to improve efficiency.

Conclusion

The environmental benefits of bolt cold forging machines are substantial and multifaceted. By reducing energy consumption, minimizing waste, and lowering emissions, these machines represent a sustainable alternative to traditional manufacturing methods. As industries strive to meet eco-conscious goals, the adoption of bolt cold forging technology will play a pivotal role in shaping a greener future for manufacturing. Embracing these advancements not only benefits the environment but also positions companies as leaders in sustainable practices, driving innovation and responsibility within the industry.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us