Mastering the Art of U Bolt Bending: A Comprehensive Guide to Precision Engineering

Summary:

Mastering the Art of U Bolt Bending: A Comprehensive Guide

Table of Contents

1. Introduction to U Bolt Bending

2. Understanding U Bolts and Their Applications

3. Essential Tools for U Bolt Bending

4. U Bolt Bending Techniques

5. Calculating Bend Radius and Angles

6. Quality Control in U Bolt Bending

7. Common Mistakes in U Bolt Bending

8. Future Trends in U Bolt Ma

Mastering the Art of U Bolt Bending: A Comprehensive Guide

Table of Contents

- 1. Introduction to U Bolt Bending

- 2. Understanding U Bolts and Their Applications

- 3. Essential Tools for U Bolt Bending

- 4. U Bolt Bending Techniques

- 5. Calculating Bend Radius and Angles

- 6. Quality Control in U Bolt Bending

- 7. Common Mistakes in U Bolt Bending

- 8. Future Trends in U Bolt Manufacturing

- 9. Conclusion

- 10. FAQs

1. Introduction to U Bolt Bending

U bolts are a crucial component in various industries, providing support and stability in applications ranging from automotive to structural engineering. Mastering the art of U bolt bending involves understanding the material properties, precision techniques, and the tools required to achieve the perfect bend. This guide aims to provide a comprehensive overview of the entire bending process, helping you enhance your skills and improve your outcomes.

2. Understanding U Bolts and Their Applications

U bolts are shaped like the letter "U" and are primarily used to secure round objects or components, such as pipes, in place. They are commonly found in:

2.1 Automotive Applications

In the automotive industry, U bolts are used to secure leaf springs or axle components. Their ability to withstand significant tension makes them ideal for this purpose.

2.2 Construction and Structural Applications

In construction, U bolts are utilized to anchor and support structures, aiding in the stability of frameworks and foundations.

2.3 Agricultural Uses

Agricultural machinery often employs U bolts to hold parts together, ensuring operational efficiency and durability in harsh environments.

Understanding these applications can help you appreciate the importance of precision in the bending process, as any deviation can lead to failures in the field.

3. Essential Tools for U Bolt Bending

To achieve optimal results in U bolt bending, a specific set of tools is required. Here’s a breakdown of the essential tools:

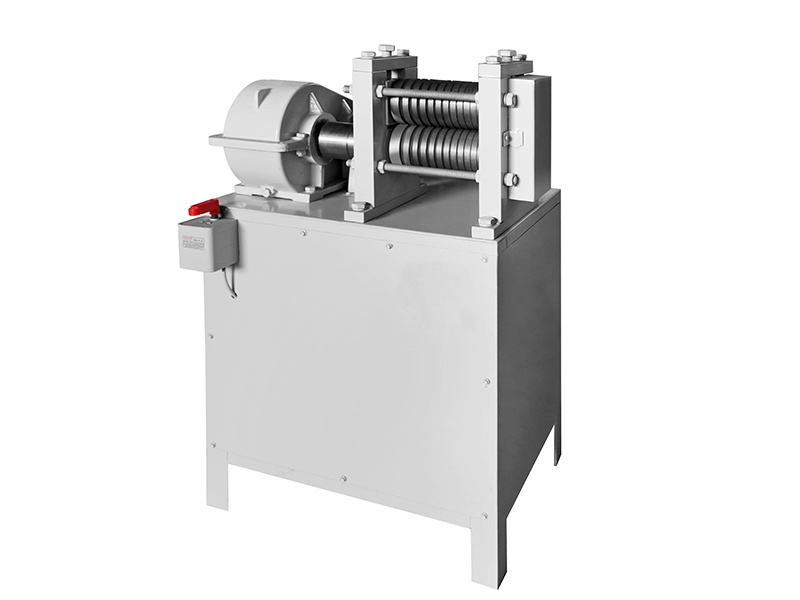

3.1 U Bolt Bending Machine

A specialized U bolt bending machine enables you to fabricate U bolts quickly and efficiently. These machines come with adjustable settings for different diameters and bending angles.

3.2 Manual Bending Tools

For smaller operations, manual bending tools such as hand benders and jigs can be very effective. They allow for precise control and are often more economical.

3.3 Measuring Instruments

Tools such as calipers and protractors are crucial for measuring the length and angles accurately. Precision is key in achieving the desired bend.

3.4 Safety Equipment

Safety should never be compromised. Always wear protective goggles and gloves when operating bending machinery to prevent injuries.

4. U Bolt Bending Techniques

Once you have the right tools, the next step is mastering the bending techniques.

4.1 The Basic Bending Process

To begin with, ensure the material is securely clamped in the machine or fixture. Gradually apply pressure to bend the material, ensuring even force is distributed throughout the length of the U bolt.

4.2 Advanced Bending Techniques

Advanced techniques may include multiple bend processes or the use of heat. Heating the material can make it more malleable, allowing for tighter bends without compromising integrity.

4.3 Testing the Bend

After bending, always test the finished U bolt for accuracy. This includes checking the angles and lengths against your specifications.

5. Calculating Bend Radius and Angles

Understanding how to calculate the bend radius and angles is essential for precision bending.

5.1 Important Formulas

The bend radius is determined by the thickness of the material and the diameter of the U bolt. A common formula used is:

**Bend Radius = (Material Thickness) x (Factor)**

where the factor typically ranges from 1.5 to 2, depending on the material properties.

5.2 Using Software for Calculation

In modern manufacturing settings, software tools can help automate these calculations, ensuring accuracy and efficiency.

6. Quality Control in U Bolt Bending

Quality control is an integral part of the U bolt bending process. Implementing a robust quality control system helps minimize defects and ensures that each U bolt meets the required specifications.

6.1 Inspection Methods

Regular inspections of the U bolts can be performed using gauges and measurement tools. These inspections can help identify any discrepancies early in the manufacturing process.

6.2 Documentation and Standards

Maintaining thorough documentation helps track quality control measures and compliance with industry standards. This can be crucial for industries that require strict adherence to regulations.

7. Common Mistakes in U Bolt Bending

Even experienced professionals can encounter pitfalls in the bending process. Here are some common mistakes to avoid:

7.1 Inaccurate Measurements

Failing to measure correctly can lead to ill-fitting U bolts. Always double-check measurements before commencing with bending.

7.2 Improper Tool Setup

Not calibrating or setting up the bending machine properly can result in inconsistent bends. Regular maintenance and checks can mitigate this issue.

8. Future Trends in U Bolt Manufacturing

As technology advances, new trends are emerging in U bolt manufacturing that promise to enhance efficiency and precision.

8.1 Automation in Manufacturing

The rise of automation and robotics in manufacturing processes is streamlining U bolt production, reducing labor costs while increasing precision.

8.2 Eco-Friendly Materials

Sustainable manufacturing practices are taking center stage, with more companies shifting towards eco-friendly materials and processes.

9. Conclusion

Mastering the art of U bolt bending requires a combination of the right tools, techniques, and a commitment to quality. By understanding the nuances of U bolt applications, employing accurate bending methods, and maintaining stringent quality control, manufacturers can produce high-quality U bolts that meet industry standards. As technology continues to evolve, staying informed about new trends will further enhance your capabilities in this essential manufacturing field.

10. FAQs

10.1 What materials are commonly used for U bolts?

Most U bolts are made from materials such as stainless steel, carbon steel, and galvanized steel, depending on the application and required strength.

10.2 How do I determine the correct size U bolt for my application?

To determine the correct size, consider the diameter of the object being secured and the load it needs to bear. Refer to manufacturer specifications for precise measurements.

10.3 Can I bend U bolts manually?

Yes, U bolts can be bent manually using hand tools. However, this requires skill and experience to ensure accurate and consistent results.

10.4 What are the common applications of U bolts?

U bolts are commonly used in automotive, construction, and agricultural applications, providing support and secure fastening for various components.

10.5 How can I avoid defects in U bolt bending?

To avoid defects, ensure that you measure accurately, use the appropriate tools, and maintain a consistent bending technique. Regular quality inspections will also help identify and correct issues early on.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us