Understanding the Advantages and Functionality of Inverted Wire Drawing Machines

Summary:

In the realm of metal processing machinery, the inverted wire drawing machine stands out as a vital tool for manufacturers looking to enhance their wire production capabilities. This type of machine is specifically designed to draw metal wire to precise diameters while maintaining the integrity and quality of the material being processed. The inverted design refers to the orientation in which the

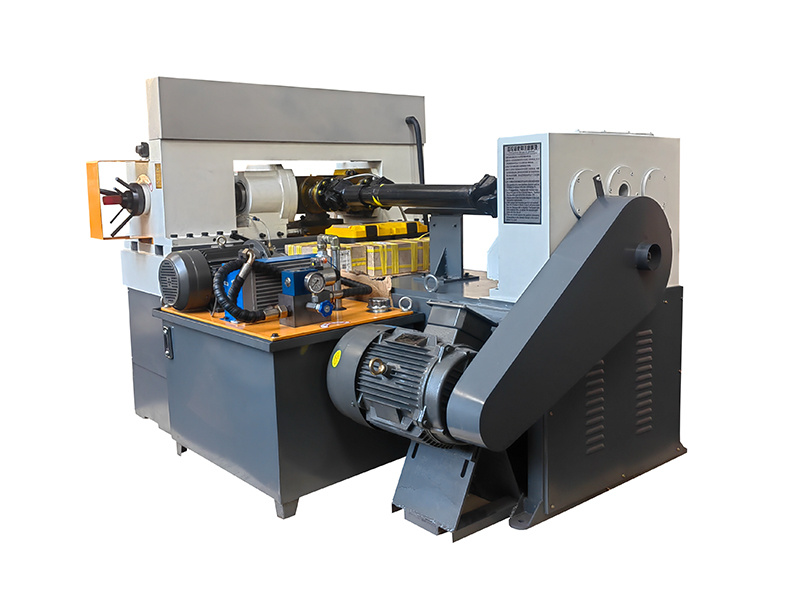

In the realm of metal processing machinery, the inverted wire drawing machine stands out as a vital tool for manufacturers looking to enhance their wire production capabilities. This type of machine is specifically designed to draw metal wire to precise diameters while maintaining the integrity and quality of the material being processed. The inverted design refers to the orientation in which the wire is drawn through the machine, allowing for enhanced control and efficiency during the drawing process.

One of the most significant advantages of using an inverted wire drawing machine is its ability to reduce the overall production time. By optimizing the drawing angle and tension, these machines can achieve higher drawing speeds compared to traditional models. This efficiency translates to increased output and reduced labor costs, making it an attractive option for manufacturers looking to maximize productivity.

Moreover, inverted wire drawing machines often feature advanced control systems that allow operators to monitor and adjust various parameters in real-time. This level of control ensures that the wire is drawn uniformly, resulting in a consistent product quality. The ability to quickly adapt to different wire sizes and materials also provides flexibility, accommodating a wide range of applications in industries such as automotive, aerospace, and construction.

Another notable benefit of these machines is their ability to minimize waste during the wire drawing process. The inverted configuration helps in better material utilization, reducing the amount of scrap generated. This eco-friendly aspect is increasingly important in today's manufacturing landscape, where sustainability is becoming a priority for many companies.

Safety is also a paramount consideration in the design of inverted wire drawing machines. These machines are equipped with various safety features to protect operators from potential hazards associated with the high-speed drawing process. Training operators on the correct usage and safety protocols is essential to ensure a safe working environment.

In summary, inverted wire drawing machines play a crucial role in enhancing wire production efficiency and quality in the metal processing industry. Their innovative design, coupled with advanced technology, allows manufacturers to optimize their operations while minimizing waste. As industries continue to evolve, investing in such advanced machinery can be a significant factor in maintaining a competitive edge in the market. Whether you are looking to upgrade your existing equipment or explore new production techniques, understanding the capabilities of inverted wire drawing machines is essential for any metal processing enterprise.

One of the most significant advantages of using an inverted wire drawing machine is its ability to reduce the overall production time. By optimizing the drawing angle and tension, these machines can achieve higher drawing speeds compared to traditional models. This efficiency translates to increased output and reduced labor costs, making it an attractive option for manufacturers looking to maximize productivity.

Moreover, inverted wire drawing machines often feature advanced control systems that allow operators to monitor and adjust various parameters in real-time. This level of control ensures that the wire is drawn uniformly, resulting in a consistent product quality. The ability to quickly adapt to different wire sizes and materials also provides flexibility, accommodating a wide range of applications in industries such as automotive, aerospace, and construction.

Another notable benefit of these machines is their ability to minimize waste during the wire drawing process. The inverted configuration helps in better material utilization, reducing the amount of scrap generated. This eco-friendly aspect is increasingly important in today's manufacturing landscape, where sustainability is becoming a priority for many companies.

Safety is also a paramount consideration in the design of inverted wire drawing machines. These machines are equipped with various safety features to protect operators from potential hazards associated with the high-speed drawing process. Training operators on the correct usage and safety protocols is essential to ensure a safe working environment.

In summary, inverted wire drawing machines play a crucial role in enhancing wire production efficiency and quality in the metal processing industry. Their innovative design, coupled with advanced technology, allows manufacturers to optimize their operations while minimizing waste. As industries continue to evolve, investing in such advanced machinery can be a significant factor in maintaining a competitive edge in the market. Whether you are looking to upgrade your existing equipment or explore new production techniques, understanding the capabilities of inverted wire drawing machines is essential for any metal processing enterprise.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us