Optimizing Efficiency with Welding Wire Drum Packing Machines

Summary:

Welding wire drum packing machines are specialized equipment designed to automate the packaging of welding wire into drums. This process is essential for industries that require consistent and reliable packaging solutions for their products. The primary function of these machines is to efficiently fill, weigh, and seal drums with welding wire, ultimately improving productivity and reducing labor c

Welding wire drum packing machines are specialized equipment designed to automate the packaging of welding wire into drums. This process is essential for industries that require consistent and reliable packaging solutions for their products. The primary function of these machines is to efficiently fill, weigh, and seal drums with welding wire, ultimately improving productivity and reducing labor costs.

One of the main advantages of using welding wire drum packing machines is their ability to enhance efficiency. Traditional manual packaging methods can be time-consuming and prone to human error. In contrast, automated machines ensure precise filling and sealing, which minimizes waste and maximizes the use of materials. This level of accuracy is vital for maintaining uniformity in product quality, which is particularly important in industries relying on welding wire for critical applications.

Moreover, these packing machines can significantly improve throughput. With the capacity to operate at high speeds, they enable manufacturers to meet growing demand without compromising quality. This efficiency is particularly beneficial in scenarios where large quantities of welding wire need to be packaged within tight deadlines, ensuring that production schedules are maintained.

Another key feature of welding wire drum packing machines is their adaptability. They can be customized to handle various drum sizes and types, accommodating different welding wire specifications. This versatility allows manufacturers to streamline their operations and reduce the need for multiple packaging systems, ultimately resulting in cost savings.

Additionally, these machines often come equipped with advanced technology that enhances functionality and user experience. Features such as touch-screen interfaces, automated adjustments, and real-time monitoring systems facilitate easy operation and maintenance, making them an attractive option for manufacturers seeking to modernize their packaging processes.

In summary, welding wire drum packing machines are indispensable tools in the manufacturing sector. Their ability to automate packaging, improve efficiency, and ensure product consistency makes them a valuable investment for companies looking to optimize their processes. By integrating these machines into their operations, manufacturers can not only enhance productivity but also maintain high standards of quality in their welding wire products. As industries evolve and demand for efficient packaging solutions continues to rise, welding wire drum packing machines will play a crucial role in shaping the future of manufacturing and processing machinery.

One of the main advantages of using welding wire drum packing machines is their ability to enhance efficiency. Traditional manual packaging methods can be time-consuming and prone to human error. In contrast, automated machines ensure precise filling and sealing, which minimizes waste and maximizes the use of materials. This level of accuracy is vital for maintaining uniformity in product quality, which is particularly important in industries relying on welding wire for critical applications.

Moreover, these packing machines can significantly improve throughput. With the capacity to operate at high speeds, they enable manufacturers to meet growing demand without compromising quality. This efficiency is particularly beneficial in scenarios where large quantities of welding wire need to be packaged within tight deadlines, ensuring that production schedules are maintained.

Another key feature of welding wire drum packing machines is their adaptability. They can be customized to handle various drum sizes and types, accommodating different welding wire specifications. This versatility allows manufacturers to streamline their operations and reduce the need for multiple packaging systems, ultimately resulting in cost savings.

Additionally, these machines often come equipped with advanced technology that enhances functionality and user experience. Features such as touch-screen interfaces, automated adjustments, and real-time monitoring systems facilitate easy operation and maintenance, making them an attractive option for manufacturers seeking to modernize their packaging processes.

In summary, welding wire drum packing machines are indispensable tools in the manufacturing sector. Their ability to automate packaging, improve efficiency, and ensure product consistency makes them a valuable investment for companies looking to optimize their processes. By integrating these machines into their operations, manufacturers can not only enhance productivity but also maintain high standards of quality in their welding wire products. As industries evolve and demand for efficient packaging solutions continues to rise, welding wire drum packing machines will play a crucial role in shaping the future of manufacturing and processing machinery.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

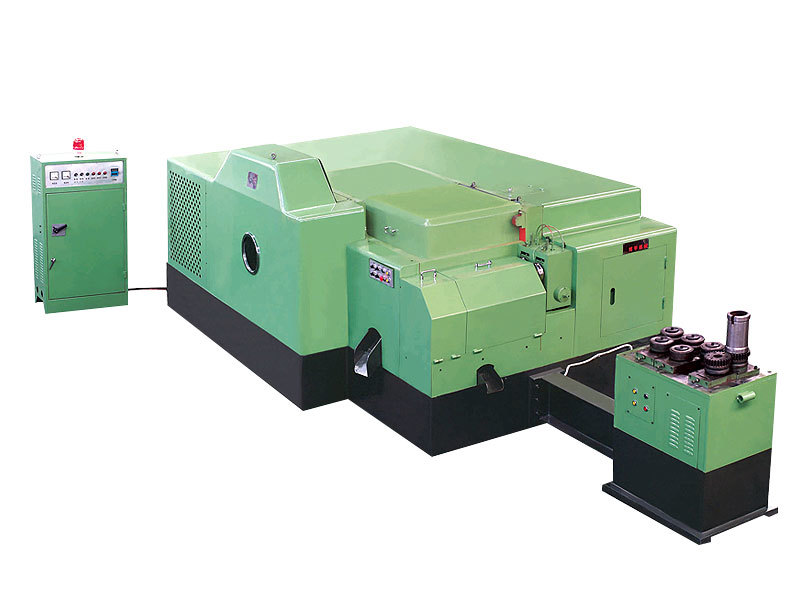

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us