How to Choose the Right U Bolt Bending Machine for Your Needs

Summary:

How to Choose the Right U Bolt Bending Machine for Your Needs

In the world of manufacturing, precision and efficiency are the keys to success. When it comes to producing U bolts, choosing the right bending machine can significantly impact your workflow and product quality. This detailed guide will navigate you through the essential factors to consider when selecting a U bolt bending machine that s

How to Choose the Right U Bolt Bending Machine for Your Needs

In the world of manufacturing, precision and efficiency are the keys to success. When it comes to producing U bolts, choosing the right bending machine can significantly impact your workflow and product quality. This detailed guide will navigate you through the essential factors to consider when selecting a U bolt bending machine that suits your needs.

Understanding U Bolt Bending Machines

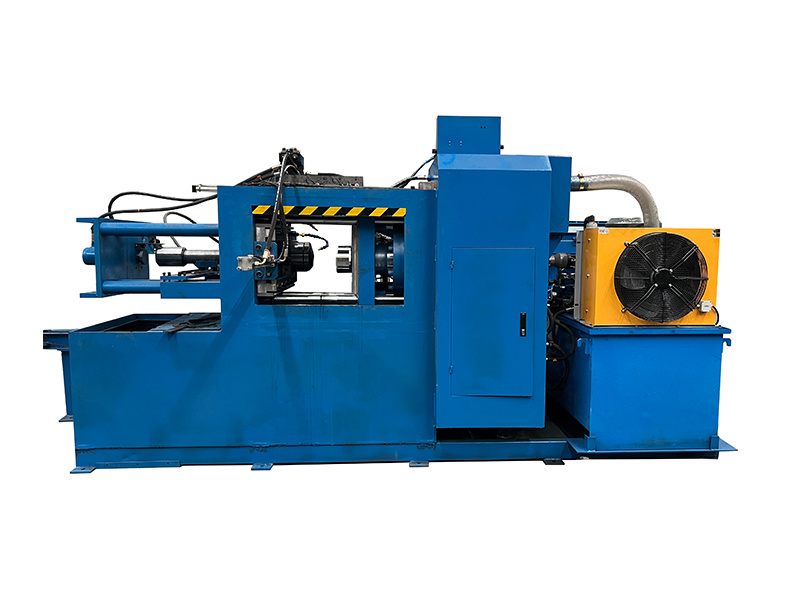

U bolt bending machines are specialized equipment designed for creating U-shaped bolts from various materials. These machines offer automated bending processes that enhance both speed and accuracy. Understanding how these machines function and their specifications is crucial in making an informed purchase.

The Importance of U Bolt Bending Machines in Manufacturing

U bolt bending machines play a vital role in industries such as automotive, construction, and machinery manufacturing. They ensure that U bolts are produced consistently, reducing the risk of defects. With the right machine, manufacturers can achieve tighter tolerances and improved surface finishes, ultimately leading to higher customer satisfaction.

Key Factors to Consider When Choosing a U Bolt Bending Machine

Selecting the ideal U bolt bending machine is a multifaceted decision. Below are the primary factors to consider:

1. Type of Machine: Manual vs. Automatic

The choice between a manual and an automatic U bolt bending machine depends on your production volume and budget.

- **Manual Machines:** These are often less expensive and suitable for smaller operations or custom jobs. However, they require more labor and may not provide the same level of consistency as automatic models.

- **Automatic Machines:** Designed for high-volume production, these machines offer speed and efficiency. While they may come with a higher initial investment, they can lead to significant savings in labor costs over time.

2. Material Compatibility

Different U bolt bending machines are designed to work with various materials, including steel, aluminum, and other alloys. Assessing the materials you plan to use is essential. Ensure the machine you choose can handle the specific thickness and type of material required for your applications.

Material Strength and Durability

The machine’s construction must also match the strength requirements of the materials being processed. Investing in a robust machine made from high-quality materials will ensure longevity and reliability, reducing the likelihood of breakdowns.

3. Bending Capacity and Range

Understanding the bending capacity is crucial. This includes the maximum diameter of the U bolts that the machine can handle and the angles it can achieve. Make sure to analyze your production requirements thoroughly and choose a machine that can accommodate both current and future needs.

4. Control Systems and Technology

Modern U bolt bending machines come equipped with advanced control systems that enhance precision and ease of use. Look for machines with:

- **User-Friendly Interfaces:** Intuitive controls make setup and operation simpler, reducing the learning curve for operators.

- **Programmable Settings:** Automated settings for different bolt sizes and specifications can drastically improve efficiency.

- **Real-time Monitoring:** Machines with monitoring capabilities can help track performance and alert you to potential issues before they become problems.

5. Maintenance and Service Requirements

Every machine requires maintenance, and understanding the service requirements of your U bolt bending machine is crucial. Investigate:

- **Warranty and Support:** A good warranty and responsive customer support are essential for minimizing downtime.

- **Ease of Maintenance:** Machines that are easier to maintain can save you time and costs in the long run. Check for the availability of spare parts and the frequency of required maintenance.

Comparing Different U Bolt Bending Machines

Once you have established your needs, the next step is to compare different U bolt bending machines in the market. Here’s how to effectively compare them:

1. Research Brands and Models

Not all manufacturers produce machines of equal quality. Conduct thorough research on reputable brands known for reliability and performance. Look for reviews, testimonials, and case studies that highlight the experiences of other users.

2. Analyze Features and Specifications

Create a checklist of must-have features and specifications based on the factors discussed earlier. Compare different models against this checklist to see which ones meet your criteria.

3. Consider the Price Point

While it’s essential to stay within your budget, consider the long-term value of the machine. A slightly higher investment in a quality machine may yield better returns over time through efficiency and reduced operational costs.

Real-Life Applications of U Bolt Bending Machines

To better understand the utility of U bolt bending machines, let’s explore some real-world applications:

1. Automotive Manufacturing

In the automotive industry, U bolts are essential for securing various components. Using a reliable bending machine ensures that these bolts meet the stringent safety and quality standards required in vehicle manufacturing.

2. Construction Projects

In construction, U bolts are used to anchor structures and secure elements in place. Consistent quality and strength are paramount, making a well-chosen bending machine critical for construction firms.

Frequently Asked Questions (FAQs)

1. What is the average cost of a U bolt bending machine?

The cost can vary significantly depending on the type, features, and brand, ranging from a few thousand to tens of thousands of dollars.

2. How long does it take to set up a U bolt bending machine?

Setup time can vary based on the complexity of the machine and the operator's experience. Generally, it may take anywhere from a few hours to a couple of days.

3. Can I use a U bolt bending machine for other types of bending?

Many U bolt bending machines can also handle other bending tasks, but it’s essential to verify the machine's specifications to ensure compatibility.

4. What maintenance is required for U bolt bending machines?

Regular maintenance includes lubricating moving parts, checking alignment, and cleaning debris. Refer to the manufacturer's manual for specific guidelines.

5. How can I increase the lifespan of my U bolt bending machine?

To extend the machine's lifespan, adhere strictly to maintenance schedules, train operators on proper use, and address any issues promptly.

Conclusion

Choosing the right U bolt bending machine is a critical decision that can influence the efficiency and quality of your manufacturing process. By understanding the different types of machines, their capabilities, and your specific production needs, you can make an informed choice. Investing in the right equipment not only boosts productivity but also enhances the overall quality of your products. With a comprehensive understanding of these factors, you are now equipped to select the ideal U bolt bending machine that aligns with your operational goals.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us