Understanding Inverted Wire Drawing Machines: A Key Component in Metal Processing

Summary:

Inverted wire drawing machines are specialized equipment used in the manufacturing and processing of metal wires, playing a crucial role in enhancing overall productivity and quality. These machines operate on the principle of drawing metal through a die, which reduces the diameter of the wire while increasing its length. The inverted design of these machines sets them apart, as they allow for opt

Inverted wire drawing machines are specialized equipment used in the manufacturing and processing of metal wires, playing a crucial role in enhancing overall productivity and quality. These machines operate on the principle of drawing metal through a die, which reduces the diameter of the wire while increasing its length. The inverted design of these machines sets them apart, as they allow for optimal material handling and improved operator safety.

One of the primary advantages of inverted wire drawing machines is their ability to maintain consistent tension throughout the drawing process. This is achieved through the innovative design that positions the spool and die in such a way that it reduces the risk of wire breakage. The consistent tension not only improves the quality of the finished wire but also minimizes the potential for defects, making it a preferred choice for manufacturers aiming for high standards.

Moreover, inverted wire drawing machines are engineered to support various wire types, including ferrous and non-ferrous metals. This versatility allows manufacturers to process a wide range of materials, catering to diverse industry needs. The machines can be configured for different wire sizes and specifications, enabling customization for specific applications, which is a significant advantage in today’s competitive market.

The operational efficiency of these machines is further enhanced by their automation features. Many modern inverted wire drawing machines come equipped with advanced controls and monitoring systems that facilitate real-time adjustments during the drawing process. This level of automation not only streamlines operations but also significantly reduces labor costs and minimizes human error, leading to a more reliable and efficient production environment.

In addition to efficiency and versatility, inverted wire drawing machines contribute to sustainability in manufacturing. By optimizing the wire drawing process and reducing material waste, these machines help manufacturers adhere to environmental regulations while maintaining profitability. The ability to recycle scrap material from the drawing process is another positive aspect, further supporting sustainable practices.

Maintenance and upkeep of inverted wire drawing machines are also essential to ensure longevity and optimal performance. Regular inspections and timely servicing help prevent downtime and extend the machine's operational life. Manufacturers often benefit from investing in training for their operators, ensuring that they are skilled in the nuances of operating and maintaining these complex machines.

In conclusion, inverted wire drawing machines are indispensable in the metal processing industry, offering numerous benefits that enhance productivity, quality, and sustainability. Their innovative design and advanced features make them a vital component for manufacturers looking to improve their wire production processes and meet the ever-evolving demands of the market. Understanding the functionality and advantages of these machines can lead to better investment decisions and ultimately contribute to a more efficient manufacturing environment.

One of the primary advantages of inverted wire drawing machines is their ability to maintain consistent tension throughout the drawing process. This is achieved through the innovative design that positions the spool and die in such a way that it reduces the risk of wire breakage. The consistent tension not only improves the quality of the finished wire but also minimizes the potential for defects, making it a preferred choice for manufacturers aiming for high standards.

Moreover, inverted wire drawing machines are engineered to support various wire types, including ferrous and non-ferrous metals. This versatility allows manufacturers to process a wide range of materials, catering to diverse industry needs. The machines can be configured for different wire sizes and specifications, enabling customization for specific applications, which is a significant advantage in today’s competitive market.

The operational efficiency of these machines is further enhanced by their automation features. Many modern inverted wire drawing machines come equipped with advanced controls and monitoring systems that facilitate real-time adjustments during the drawing process. This level of automation not only streamlines operations but also significantly reduces labor costs and minimizes human error, leading to a more reliable and efficient production environment.

In addition to efficiency and versatility, inverted wire drawing machines contribute to sustainability in manufacturing. By optimizing the wire drawing process and reducing material waste, these machines help manufacturers adhere to environmental regulations while maintaining profitability. The ability to recycle scrap material from the drawing process is another positive aspect, further supporting sustainable practices.

Maintenance and upkeep of inverted wire drawing machines are also essential to ensure longevity and optimal performance. Regular inspections and timely servicing help prevent downtime and extend the machine's operational life. Manufacturers often benefit from investing in training for their operators, ensuring that they are skilled in the nuances of operating and maintaining these complex machines.

In conclusion, inverted wire drawing machines are indispensable in the metal processing industry, offering numerous benefits that enhance productivity, quality, and sustainability. Their innovative design and advanced features make them a vital component for manufacturers looking to improve their wire production processes and meet the ever-evolving demands of the market. Understanding the functionality and advantages of these machines can lead to better investment decisions and ultimately contribute to a more efficient manufacturing environment.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

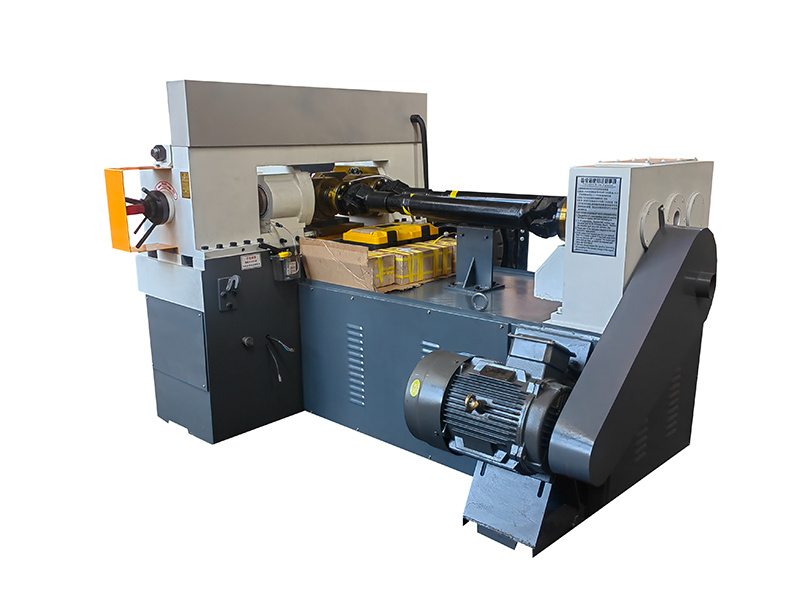

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us