Understanding the Benefits and Functions of Inverted Wire Drawing Machines

Summary:

Inverted wire drawing machines are advanced pieces of equipment utilized in the metalworking sector, specifically designed to produce wires of various diameters and materials. These machines operate on the principle of drawing metal through a series of dies or reductive openings, effectively reducing the diameter of the wire while increasing its length. The inverted design of these machines offers

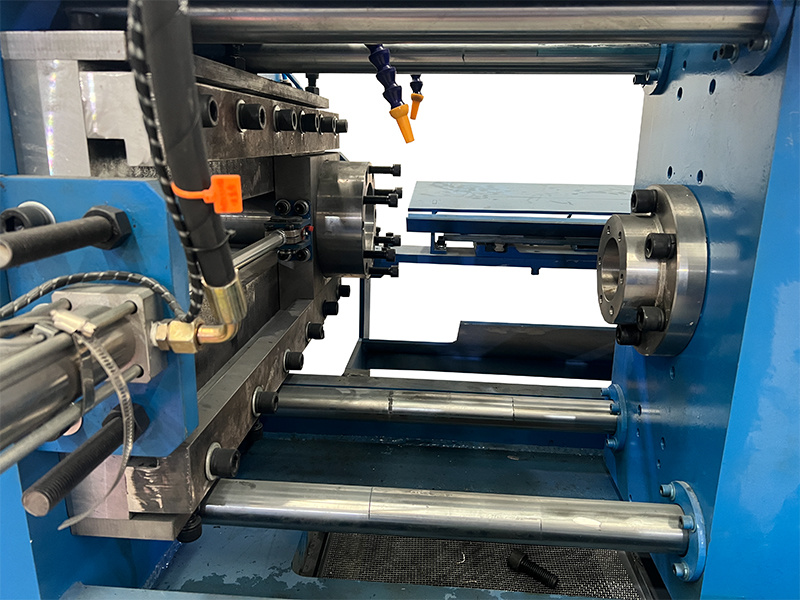

Inverted wire drawing machines are advanced pieces of equipment utilized in the metalworking sector, specifically designed to produce wires of various diameters and materials. These machines operate on the principle of drawing metal through a series of dies or reductive openings, effectively reducing the diameter of the wire while increasing its length. The inverted design of these machines offers several distinct advantages over traditional wire drawing setups, making them a preferred choice for many manufacturers.

One of the key benefits of inverted wire drawing machines is their ability to minimize the overall footprint required for operation. By positioning the drawing dies above the spool, these machines allow for a more compact layout, which is particularly advantageous in facilities with limited space. This design not only conserves valuable floor area but also facilitates easier access to the machine components for maintenance and adjustments.

Moreover, inverted wire drawing machines enhance the efficiency of the wire drawing process. The gravitational pull assists in the smooth feeding of the wire through the drawing dies, reducing friction and wear on both the wire and the machine. This results in lower energy consumption and extended tool life, contributing to overall operational efficiency. Additionally, the improved alignment of the wire during the drawing process minimizes the risk of defects, ensuring a higher-quality end product that meets industry standards.

Another significant aspect of these machines is their versatility. Inverted wire drawing machines can handle a wide variety of materials, including various grades of steel, aluminum, copper, and specialty alloys. This versatility is crucial for manufacturers looking to adapt to changing market demands or diversify their product offerings. Furthermore, these machines can be equipped with advanced features such as automatic die adjustment, real-time monitoring systems, and integrated cooling solutions, allowing for enhanced control over the drawing process.

The ease of operation associated with inverted wire drawing machines is also noteworthy. Many modern machines come with user-friendly interfaces, enabling operators to quickly set parameters and make adjustments without extensive training. This attribute not only accelerates production times but also supports a safer working environment by reducing the potential for human error.

In conclusion, inverted wire drawing machines play a vital role in the manufacturing and processing of metal wires, offering numerous advantages including compact design, improved efficiency, versatility, and user-friendliness. Their ability to produce high-quality wires while minimizing operational costs makes them an essential investment for businesses in the metalworking industry. Understanding the functionality and benefits of these machines can help manufacturers make informed decisions that enhance their production capabilities and competitive edge.

One of the key benefits of inverted wire drawing machines is their ability to minimize the overall footprint required for operation. By positioning the drawing dies above the spool, these machines allow for a more compact layout, which is particularly advantageous in facilities with limited space. This design not only conserves valuable floor area but also facilitates easier access to the machine components for maintenance and adjustments.

Moreover, inverted wire drawing machines enhance the efficiency of the wire drawing process. The gravitational pull assists in the smooth feeding of the wire through the drawing dies, reducing friction and wear on both the wire and the machine. This results in lower energy consumption and extended tool life, contributing to overall operational efficiency. Additionally, the improved alignment of the wire during the drawing process minimizes the risk of defects, ensuring a higher-quality end product that meets industry standards.

Another significant aspect of these machines is their versatility. Inverted wire drawing machines can handle a wide variety of materials, including various grades of steel, aluminum, copper, and specialty alloys. This versatility is crucial for manufacturers looking to adapt to changing market demands or diversify their product offerings. Furthermore, these machines can be equipped with advanced features such as automatic die adjustment, real-time monitoring systems, and integrated cooling solutions, allowing for enhanced control over the drawing process.

The ease of operation associated with inverted wire drawing machines is also noteworthy. Many modern machines come with user-friendly interfaces, enabling operators to quickly set parameters and make adjustments without extensive training. This attribute not only accelerates production times but also supports a safer working environment by reducing the potential for human error.

In conclusion, inverted wire drawing machines play a vital role in the manufacturing and processing of metal wires, offering numerous advantages including compact design, improved efficiency, versatility, and user-friendliness. Their ability to produce high-quality wires while minimizing operational costs makes them an essential investment for businesses in the metalworking industry. Understanding the functionality and benefits of these machines can help manufacturers make informed decisions that enhance their production capabilities and competitive edge.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us