Maximizing Metal Quality: The Role of Inverted Wire Drawing Machines in Precision Manufacturing

Summary:

Maximizing Metal Quality: The Role of Inverted Wire Drawing Machines in Precision Manufacturing

Introduction to Inverted Wire Drawing Machines

In the world of metal manufacturing, **precision** and **quality** are paramount. Inverted wire drawing machines play a crucial role in achieving these objectives. Unlike traditional wire drawing methods, these machines offer unique advantages that signific

Maximizing Metal Quality: The Role of Inverted Wire Drawing Machines in Precision Manufacturing

Introduction to Inverted Wire Drawing Machines

In the world of metal manufacturing, **precision** and **quality** are paramount. Inverted wire drawing machines play a crucial role in achieving these objectives. Unlike traditional wire drawing methods, these machines offer unique advantages that significantly enhance the overall quality of the metal produced. This article delves into the various ways inverted wire drawing machines can maximize metal quality, ensuring that manufacturers can meet the increasing demands of industries like automotive, aerospace, and construction.

Understanding Inverted Wire Drawing Technology

Inverted wire drawing technology operates on a principle that differs fundamentally from conventional drawing processes. By pulling the wire through a die at an angle, it minimizes friction and reduces the chances of surface damage. This innovative approach leads to a smoother finish and enhanced mechanical properties.

How Inverted Wire Drawing Works

Inverted wire drawing machines utilize a series of **dies** designed to gradually reduce the diameter of the wire. The wire is fed into the machine, where it is drawn through a series of dies, each progressively decreasing the size of the wire. The inverted component allows for a more effective tension application and a reduction in tool wear, leading to longer operational lifespans.

Key Components of Inverted Wire Drawing Machines

Several critical components contribute to the efficiency of inverted wire drawing machines:

- **Drawing Dies**: These are specialized tools that shape the wire and control its diameter.

- **Tension Mechanisms**: These ensure that the wire is drawn smoothly without causing defects.

- **Lubrication Systems**: Essential for reducing friction and heat, enhancing the final product's quality.

The Importance of Metal Quality in Manufacturing

Metal quality is not just about appearance; it directly affects the performance and reliability of the final product. High-quality metals exhibit improved strength, durability, and resistance to corrosion. In industries where safety and performance are crucial, such as aerospace and automotive, the stakes are even higher.

Defect Reduction Through Advanced Technology

Inverted wire drawing machines significantly lower the incidence of common defects associated with traditional drawing methods. By minimizing friction and optimizing tension, these machines reduce issues such as:

- **Surface Imperfections**: Scratches and blemishes are less likely to occur.

- **Dimensional Variability**: Consistency in wire diameter is maintained throughout the production process.

- **Material Waste**: The efficient use of materials leads to lower production costs.

Enhancing Mechanical Properties

The mechanical properties of metals are crucial for their performance in various applications. Inverted wire drawing machines enhance properties such as tensile strength and ductility. The controlled drawing process improves grain structure, leading to stronger and more resilient wires.

Applications of Inverted Wire Drawing Machines

The versatility of inverted wire drawing machines makes them suitable for various applications across multiple industries.

1. Automotive Manufacturing

In the automotive sector, the demand for high-quality wires and components is significant. Inverted wire drawing machines produce wires for springs, cables, and other essential components that require superior strength and flexibility.

2. Aerospace Engineering

Aerospace applications often require materials that can withstand extreme conditions. Inverted wire drawing machines provide wires that meet stringent specifications for reliability and performance.

3. Construction Materials

In the construction industry, the strength and durability of wire products, such as rebar and mesh, are critical. The enhanced quality achieved through inverted wire drawing methods ensures that these materials can withstand heavy loads and harsh environments.

Best Practices for Optimizing Inverted Wire Drawing Machines

To maximize the benefits of inverted wire drawing machines, manufacturers should adopt specific best practices:

1. Regular Maintenance

Scheduled maintenance is essential for ensuring that the machines operate at peak efficiency. Regular checks on the lubrication systems, tension mechanisms, and drawing dies will prevent unexpected breakdowns and maintain product quality.

2. Proper Operator Training

Well-trained operators are crucial for maximizing the machine's potential. Training programs should focus on understanding machine settings, troubleshooting common issues, and monitoring product quality throughout the drawing process.

3. Quality Control Measures

Implementing stringent quality control measures at various production stages ensures that the final product meets the required specifications. Regular inspections can identify defects early, allowing for timely corrections.

4. Material Selection

Choosing the right materials for drawing is vital. The composition of the wire affects its drawability and final properties. Manufacturers should work closely with suppliers to ensure they are using high-quality raw materials.

Future Trends in Wire Drawing Technology

As technology evolves, so do the capabilities of inverted wire drawing machines. Future trends may include:

1. Automation and AI Integration

The integration of automation and artificial intelligence can further enhance the efficiency of inverted wire drawing machines. Smart systems can monitor production parameters in real-time, optimizing the drawing process and minimizing defects.

2. Smart Materials

Advancements in material science may lead to the development of smart alloys that can be processed through inverted wire drawing, offering even greater performance characteristics.

Common FAQs about Inverted Wire Drawing Machines

1. What is the primary advantage of inverted wire drawing machines?

The primary advantage is the ability to produce high-quality wires with fewer defects, leading to improved mechanical properties and surface finishes.

2. How does inverted wire drawing differ from conventional methods?

Inverted wire drawing minimizes friction and tension-related issues, resulting in a smoother finish and better dimensional control compared to traditional methods.

3. What materials can be processed using inverted wire drawing machines?

These machines can process various metals, including steel, copper, and aluminum, making them versatile for multiple applications.

4. Can inverted wire drawing machines improve production efficiency?

Yes, the efficient design of inverted wire drawing machines allows for faster production speeds and reduced material waste, enhancing overall efficiency.

5. Are there specific maintenance requirements for these machines?

Regular maintenance is essential, including lubrication, tension adjustments, and inspections of drawing dies to ensure optimal performance.

Conclusion

Inverted wire drawing machines have revolutionized the metal manufacturing landscape by maximizing quality and efficiency. Their ability to produce superior metal products while minimizing defects sets them apart from traditional methods. As technology continues to advance, these machines will likely play an even more significant role in the future of metal processing. By adopting best practices and staying updated on industry trends, manufacturers can harness the full potential of inverted wire drawing machines, ensuring that they remain competitive in an increasingly demanding marketplace.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

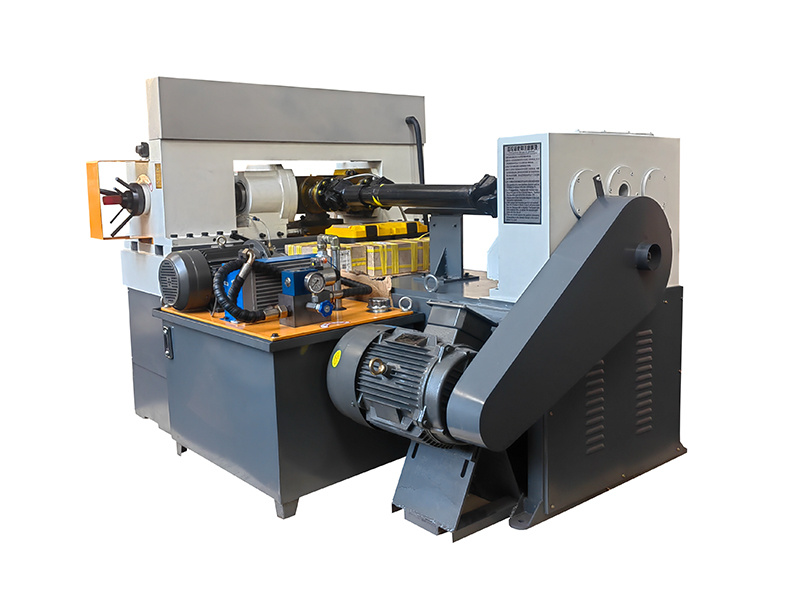

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us