Revolutionizing Manufacturing with Automatic U Bolt Bending Machines

Summary:

In the realm of manufacturing and processing machinery, the Automatic U Bolt Bending Machine stands out as a vital tool for producing high-quality, precise U bolts. These machines are engineered to automate the bending process, significantly reducing labor costs and increasing production efficiency. By understanding the intricacies of these machines, manufacturers can leverage their capabilities t

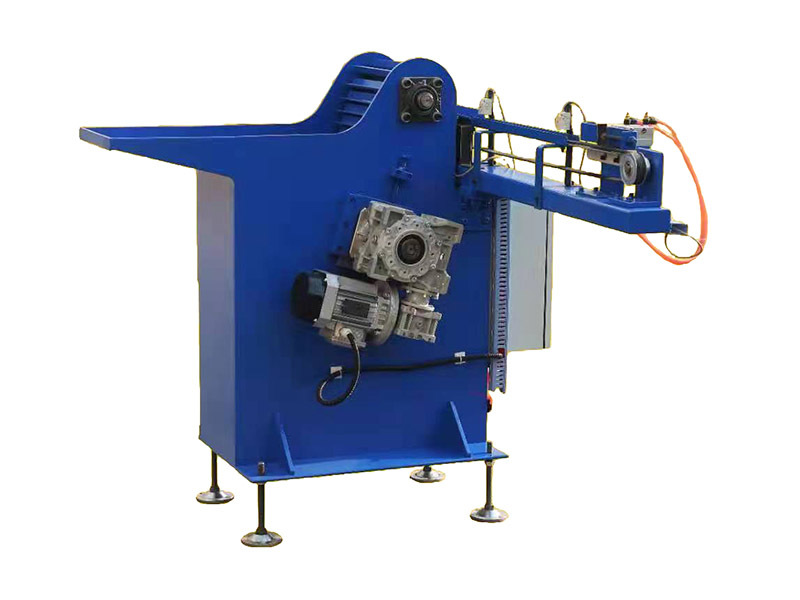

In the realm of manufacturing and processing machinery, the Automatic U Bolt Bending Machine stands out as a vital tool for producing high-quality, precise U bolts. These machines are engineered to automate the bending process, significantly reducing labor costs and increasing production efficiency. By understanding the intricacies of these machines, manufacturers can leverage their capabilities to meet high demand while maintaining superior quality.

The primary function of an Automatic U Bolt Bending Machine is to bend steel rods or wires into the desired U shape with precision. This process is essential in various industries, including automotive, construction, and furniture manufacturing, where U bolts are commonly used to secure components together. The automation inherent in these machines not only streamlines production but also minimizes the risk of human error, leading to more consistent results.

One of the key advantages of using an Automatic U Bolt Bending Machine is its ability to handle multiple specifications with ease. Many advanced models are equipped with programmable interfaces, allowing operators to input different bending parameters quickly. This versatility ensures that manufacturers can produce U bolts in varying sizes and shapes without needing to invest in multiple machines.

Additionally, these machines often feature robust construction and high-quality components, contributing to their durability and reliability. For manufacturers, this translates to less downtime for maintenance and repairs, ensuring that production schedules are met without unnecessary delays. Moreover, many Automatic U Bolt Bending Machines are designed for high-speed operation, enabling businesses to ramp up their output to meet increasing demands.

Safety is another paramount consideration in the design of these machines. They typically incorporate various safety features, such as emergency stops and protective covers, to ensure that operators can work without risk. This focus on safety not only protects the workforce but also enhances the overall work environment.

As industries continue to evolve, investing in an Automatic U Bolt Bending Machine can provide a competitive edge. By automating the bending process, manufacturers can focus on optimizing other areas of production, leading to greater innovation and efficiency.

In conclusion, Automatic U Bolt Bending Machines are indispensable assets in the manufacturing landscape. Their ability to deliver precision, reduce labor costs, and enhance safety makes them a worthwhile investment for businesses looking to improve their production capabilities. By understanding the features and benefits of these machines, professionals in the industry can make informed decisions that drive their businesses forward.

The primary function of an Automatic U Bolt Bending Machine is to bend steel rods or wires into the desired U shape with precision. This process is essential in various industries, including automotive, construction, and furniture manufacturing, where U bolts are commonly used to secure components together. The automation inherent in these machines not only streamlines production but also minimizes the risk of human error, leading to more consistent results.

One of the key advantages of using an Automatic U Bolt Bending Machine is its ability to handle multiple specifications with ease. Many advanced models are equipped with programmable interfaces, allowing operators to input different bending parameters quickly. This versatility ensures that manufacturers can produce U bolts in varying sizes and shapes without needing to invest in multiple machines.

Additionally, these machines often feature robust construction and high-quality components, contributing to their durability and reliability. For manufacturers, this translates to less downtime for maintenance and repairs, ensuring that production schedules are met without unnecessary delays. Moreover, many Automatic U Bolt Bending Machines are designed for high-speed operation, enabling businesses to ramp up their output to meet increasing demands.

Safety is another paramount consideration in the design of these machines. They typically incorporate various safety features, such as emergency stops and protective covers, to ensure that operators can work without risk. This focus on safety not only protects the workforce but also enhances the overall work environment.

As industries continue to evolve, investing in an Automatic U Bolt Bending Machine can provide a competitive edge. By automating the bending process, manufacturers can focus on optimizing other areas of production, leading to greater innovation and efficiency.

In conclusion, Automatic U Bolt Bending Machines are indispensable assets in the manufacturing landscape. Their ability to deliver precision, reduce labor costs, and enhance safety makes them a worthwhile investment for businesses looking to improve their production capabilities. By understanding the features and benefits of these machines, professionals in the industry can make informed decisions that drive their businesses forward.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us