Essential Features to Look for in a Shearing and Punching Machine

Summary:

Essential Features to Look for in a Shearing and Punching Machine

Manufacturing processes in industries like leather goods, metal fabrication, and textiles often rely on specialized machinery. Among these, **shearing and punching machines** play a pivotal role in shaping materials into desired forms. Understanding the essential features of these machines can significantly impact operational effi

Essential Features to Look for in a Shearing and Punching Machine

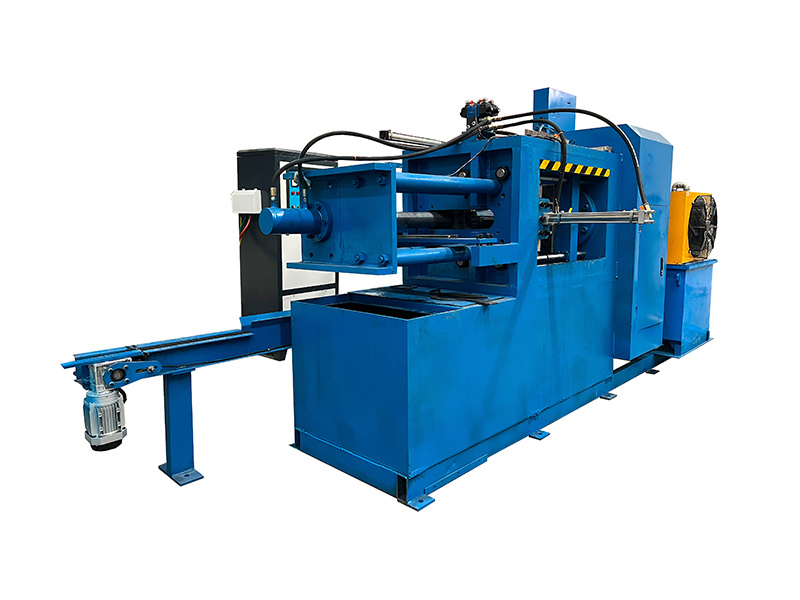

Manufacturing processes in industries like leather goods, metal fabrication, and textiles often rely on specialized machinery. Among these, **shearing and punching machines** play a pivotal role in shaping materials into desired forms. Understanding the essential features of these machines can significantly impact operational efficiency and product quality. In this article, we’ll explore the critical aspects to consider when selecting a shearing and punching machine, guiding you towards making an informed purchase.

Table of Contents

- Understanding Shearing and Punching Machines

- Key Features to Consider in Shearing and Punching Machines

- Material Compatibility and Versatility

- Precision and Accuracy in Operations

- Durability and Maintenance Requirements

- Automation and Control Systems

- Safety Features to Enhance Workplace Security

- Cost-Effectiveness and Overall Efficiency

- Frequently Asked Questions (FAQs)

- Conclusion

Understanding Shearing and Punching Machines

Shearing machines are designed to cut thick materials into specific shapes and sizes without the formation of chips or burning. Punching machines, on the other hand, are utilized to create holes in various materials. Both types of machines are extensively used in manufacturing sectors such as leather processing, automotive, aerospace, and more. Recognizing the differences and applications of each machine type is essential for making the right investment.

Key Features to Consider in Shearing and Punching Machines

When evaluating shearing and punching machines, several critical features should be at the forefront of your decision-making process. Here are the essential components to focus on:

Material Compatibility and Versatility

One of the primary considerations when selecting a shearing and punching machine is its compatibility with various materials. Depending on your manufacturing needs, the machine should be capable of cutting or punching through materials like leather, metal, plastic, and composites. A versatile machine reduces the need for multiple pieces of equipment, streamlining your production process.

Precision and Accuracy in Operations

Precision is paramount in any manufacturing process. A shearing and punching machine should deliver consistent, high-quality results. Look for machines equipped with advanced positioning systems and gauges that ensure accurate measurements and cuts. This will minimize material wastage and improve the overall quality of your products.

Durability and Maintenance Requirements

Investing in durable machinery that can withstand the rigors of daily operations is crucial. Machines made from high-quality materials will have a longer lifespan and require less frequent maintenance. It's important to consider the maintenance requirements of the machine; look for models that offer easy access to components for routine inspections and repairs.

Automation and Control Systems

Modern shearing and punching machines often feature automated systems that enhance productivity and reduce manual labor. Automated feeding mechanisms, programmable controls, and computer numerical control (CNC) capabilities can significantly improve the efficiency of your operations. Ensure that the machine you select has user-friendly control systems, making it easy for your operators to learn and manage.

Safety Features to Enhance Workplace Security

Safety should always be a top priority when choosing manufacturing equipment. Look for machines that include essential safety features such as emergency shut-off switches, safety guards, and sensors that prevent operation when safety barriers are not in place. Investing in safety features not only protects your workforce but also reduces the risk of costly accidents and downtime.

Cost-Effectiveness and Overall Efficiency

While it’s important to find a machine that meets your operational needs, cost-effectiveness is also a key consideration. Analyze the initial purchase price against the long-term operational costs, including maintenance, energy consumption, and material waste. Machines that offer higher efficiency rates can often offset their initial costs through savings in time and resources.

Frequently Asked Questions (FAQs)

1. What types of materials can be processed by shearing and punching machines?

Most shearing and punching machines can handle a variety of materials, including leather, metals (like aluminum and steel), plastics, and composites. The choice of the machine will depend on the specific materials you intend to work with.

2. How often should I perform maintenance on my shearing and punching machine?

Regular maintenance is essential for optimal performance. It’s recommended to perform routine inspections and maintenance every few months, or as specified by the manufacturer, to avoid unexpected breakdowns.

3. What are the signs of wear and tear in shearing and punching machines?

Indicators of wear and tear can include inconsistent cutting quality, unusual noises during operation, or physical damage to the machine’s components. Addressing these signs promptly can prevent more significant issues.

4. Are automated shearing and punching machines worth the investment?

Yes, automated machines typically increase efficiency and reduce labor costs. They can also improve precision and repeatability, which is crucial for large-scale production runs.

5. What safety standards should my shearing and punching machine meet?

Ensure that the machine complies with local safety regulations and standards. Look for certifications from relevant safety organizations that confirm the machine meets essential safety guidelines.

Conclusion

Selecting the right shearing and punching machine is a critical decision that can significantly impact your manufacturing operations. By focusing on essential features such as material compatibility, precision, durability, automation, safety, and cost-effectiveness, you can make an informed choice that aligns with your production goals. Investing time and resources into understanding these features will enhance your manufacturing capabilities, leading to improved product quality and operational efficiency.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us