Essential Insights into U Bolt Bending Machines: A Comprehensive Overview

Summary:

When it comes to metal fabrication, precision and efficiency are paramount. The U Bolt Bending Machine plays a crucial role in achieving these objectives. This equipment is engineered to bend metal rods into a U-shape, a common requirement in various industries including construction, automotive, and machinery manufacturing. The U Bolt is essential for fastening components securely, and the bendin

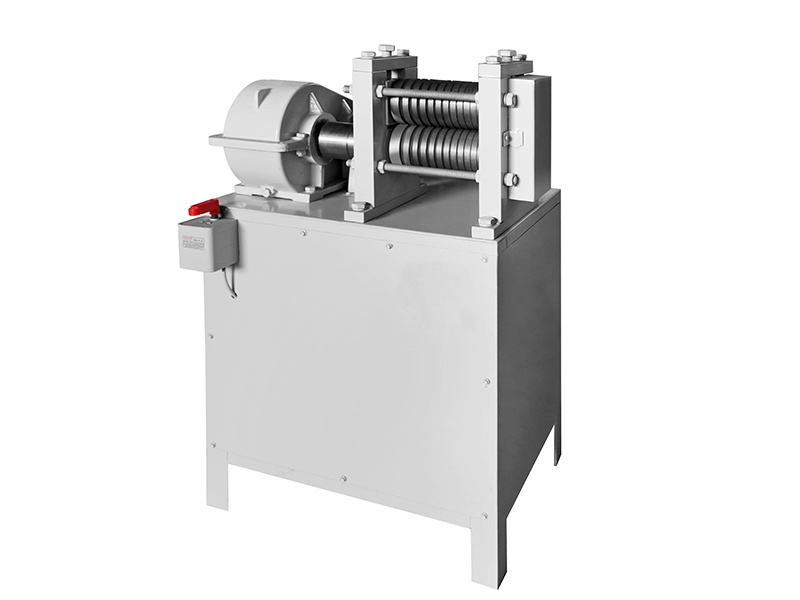

When it comes to metal fabrication, precision and efficiency are paramount. The U Bolt Bending Machine plays a crucial role in achieving these objectives. This equipment is engineered to bend metal rods into a U-shape, a common requirement in various industries including construction, automotive, and machinery manufacturing. The U Bolt is essential for fastening components securely, and the bending process must be accurate to ensure fit and strength.

One of the critical advantages of utilizing a U Bolt Bending Machine is its ability to enhance production efficiency. Traditional bending methods can be time-consuming and labor-intensive, often leading to inconsistencies in dimensions. In contrast, with a dedicated bending machine, manufacturers can achieve uniformity across multiple pieces in a fraction of the time. This not only speeds up the production process but also reduces the likelihood of errors, thus minimizing material waste.

The operation of a U Bolt Bending Machine typically involves feeding a metal rod into the machine, where it is then bent into the desired U shape through a series of controlled movements. Advanced models may incorporate digital controls and programmable settings, allowing operators to easily adjust parameters for different sizes and specifications. This flexibility makes the machine suitable for handling various types of materials, including steel and aluminum.

In addition to efficiency, the quality of the bent U Bolts is markedly improved when using a dedicated bending machine. The precision of the bends ensures that the U Bolts maintain their structural integrity under load, which is crucial for their application in critical assemblies. Higher quality U Bolts contribute to the overall reliability of the final product, instilling confidence in both manufacturers and end-users.

Furthermore, investing in a U Bolt Bending Machine can lead to long-term cost savings. By reducing labor costs, minimizing material wastage, and increasing production speed, manufacturers can enhance their profit margins. Additionally, as the demand for custom U Bolts grows, having the capability to produce them in-house can streamline operations and respond more effectively to market needs.

In summary, the U Bolt Bending Machine is an indispensable asset for manufacturers looking to improve efficiency, quality, and cost-effectiveness in their production processes. Understanding its features and benefits can empower professionals in the manufacturing sector to make informed decisions that enhance their operations and output. Whether you are looking to upgrade existing equipment or explore new production capabilities, the U Bolt Bending Machine offers a reliable solution for modern manufacturing challenges.

One of the critical advantages of utilizing a U Bolt Bending Machine is its ability to enhance production efficiency. Traditional bending methods can be time-consuming and labor-intensive, often leading to inconsistencies in dimensions. In contrast, with a dedicated bending machine, manufacturers can achieve uniformity across multiple pieces in a fraction of the time. This not only speeds up the production process but also reduces the likelihood of errors, thus minimizing material waste.

The operation of a U Bolt Bending Machine typically involves feeding a metal rod into the machine, where it is then bent into the desired U shape through a series of controlled movements. Advanced models may incorporate digital controls and programmable settings, allowing operators to easily adjust parameters for different sizes and specifications. This flexibility makes the machine suitable for handling various types of materials, including steel and aluminum.

In addition to efficiency, the quality of the bent U Bolts is markedly improved when using a dedicated bending machine. The precision of the bends ensures that the U Bolts maintain their structural integrity under load, which is crucial for their application in critical assemblies. Higher quality U Bolts contribute to the overall reliability of the final product, instilling confidence in both manufacturers and end-users.

Furthermore, investing in a U Bolt Bending Machine can lead to long-term cost savings. By reducing labor costs, minimizing material wastage, and increasing production speed, manufacturers can enhance their profit margins. Additionally, as the demand for custom U Bolts grows, having the capability to produce them in-house can streamline operations and respond more effectively to market needs.

In summary, the U Bolt Bending Machine is an indispensable asset for manufacturers looking to improve efficiency, quality, and cost-effectiveness in their production processes. Understanding its features and benefits can empower professionals in the manufacturing sector to make informed decisions that enhance their operations and output. Whether you are looking to upgrade existing equipment or explore new production capabilities, the U Bolt Bending Machine offers a reliable solution for modern manufacturing challenges.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us