Essential Features to Look for in an Inverted Wire Drawing Machine

Summary:

Essential Features to Look for in an Inverted Wire Drawing Machine

When it comes to manufacturing and metal processing, selecting the right equipment is crucial for achieving efficiency and quality. An inverted wire drawing machine plays a vital role in the production of high-quality wire products. In this article, we will explore the essential features to consider when purchasing an inverted wi

Essential Features to Look for in an Inverted Wire Drawing Machine

When it comes to manufacturing and metal processing, selecting the right equipment is crucial for achieving efficiency and quality. An inverted wire drawing machine plays a vital role in the production of high-quality wire products. In this article, we will explore the essential features to consider when purchasing an inverted wire drawing machine, ensuring your investment yields the best results for your operations.

Understanding Inverted Wire Drawing Machines

Inverted wire drawing machines are specialized devices used to reduce the diameter of wire by pulling it through a series of dies. This process is essential in various industries, including construction, automotive, and electronics. Understanding how these machines work and their applications will help you make an informed decision when selecting the right model for your needs.

The Importance of Wire Drawing in Metal Processing

Wire drawing is a critical step in metal processing that helps improve the mechanical properties of metal wires. By reducing the diameter and increasing the length of the wire, manufacturers can create products with enhanced strength, ductility, and finish. This process also allows for the production of wires with specific characteristics tailored to various applications.

Key Components of an Inverted Wire Drawing Machine

Before diving into the essential features to look for, it's important to understand the primary components that make up an inverted wire drawing machine. Some of these components include:

- **Drawing Die**: This is the heart of the machine, where the wire is drawn through to achieve the desired diameter.

- **Capstan Rollers**: These rollers facilitate the pulling of the wire through the drawing die.

- **Tension Control System**: This system maintains optimal tension during the drawing process to prevent defects.

- **Lubrication System**: Proper lubrication is necessary to reduce friction and heat, prolonging the life of the machine.

Essential Features to Consider

When selecting an inverted wire drawing machine, consider the following features that can significantly impact performance, efficiency, and overall return on investment.

1. Die Configuration

Choosing the right die configuration is fundamental for achieving your desired wire diameter and quality. Look for machines that offer:

- **Interchangeable Dies**: This feature allows for flexibility in production, enabling quick changes without significant downtime.

- **Multiple Die Sets**: Machines with multiple dies can produce various wire sizes simultaneously, increasing overall efficiency.

2. Operational Efficiency

Operational efficiency is essential for maximizing productivity. Look for machines that offer:

- **High-Speed Drawing**: Machines capable of high-speed operation can significantly reduce production time.

- **Automatic Speed Adjustments**: These adjustments compensate for wire diameter changes during the drawing process, maintaining consistent output quality.

3. Tension Control Systems

Maintaining proper tension during wire drawing is crucial for preventing defects. Advanced tension control systems should:

- **Provide Real-Time Monitoring**: Look for machines with digital displays that offer real-time feedback on tension levels.

- **Adjust Automatically**: Automated tension adjustments help maintain optimal conditions during wire drawing.

4. Lubrication Systems

A reliable lubrication system is vital for minimizing wear and tear on components. Features to consider include:

- **Automatic Lubrication**: Machines that offer automatic lubrication systems reduce the need for manual intervention, ensuring consistent performance.

- **Cooling Mechanisms**: Integrated cooling systems help dissipate heat, further protecting the machine from damage.

5. Build Quality and Durability

The longevity of your investment depends on the machine's build quality. Consider machines that are:

- **Constructed from High-Quality Materials**: Look for heavy-duty components that can withstand the rigors of continuous operation.

- **Designed for Easy Maintenance**: Machines that feature easy access to critical components make maintenance simpler and more efficient.

6. Control Systems and User Interface

The control system plays a pivotal role in the operation of an inverted wire drawing machine. Essential features include:

- **User-Friendly Interface**: A clear and intuitive interface allows operators to manage settings easily.

- **Programmable Settings**: Look for machines that offer programmable settings for different wire specifications and production runs.

7. Safety Features

Safety should not be overlooked when selecting a machine. Essential safety features include:

- **Emergency Stop Buttons**: Easily accessible emergency stops can prevent accidents during operation.

- **Safety Guards**: Protective barriers around moving parts help prevent injuries to operators.

8. Energy Efficiency

With increasing energy costs, selecting an energy-efficient machine can lead to significant savings. Key considerations include:

- **Low Power Consumption**: Machines designed to operate with lower energy requirements can reduce overall operational costs.

- **Eco-Friendly Features**: Look for machines that minimize waste and emissions, contributing to environmentally friendly operations.

Additional Considerations

Beyond the essential features, there are several additional factors to consider when selecting an inverted wire drawing machine.

1. Brand Reputation and Service Support

Investing in equipment from reputable manufacturers can provide peace of mind. Consider companies that offer:

- **Comprehensive Service Contracts**: Support packages that include regular maintenance and parts replacement can extend the life of your machine.

- **Positive Customer Reviews**: Research customer feedback to gauge the reliability and performance of the machine.

2. Compatibility with Your Production Line

Ensure that the inverted wire drawing machine is compatible with your existing production line, considering factors such as:

- **Footprint and Space Requirements**: Measure the available space to ensure the machine fits comfortably into your operation.

- **Integration with Other Equipment**: Consider how the machine will work with your current machines to streamline production processes.

3. Cost vs. Value

While it may be tempting to choose the most affordable option, it's crucial to assess the overall value. Consider:

- **Long-Term Costs**: Factor in maintenance, energy consumption, and potential downtime when evaluating price.

- **Return on Investment**: Analyze how the machine's features will enhance productivity and quality, ultimately affecting your bottom line.

Frequently Asked Questions (FAQs)

1. What is an inverted wire drawing machine used for?

An inverted wire drawing machine is primarily used to reduce the diameter of metal wires while improving their mechanical properties, making them suitable for various applications.

2. How does wire drawing improve the properties of metal wires?

Wire drawing enhances the ductility, strength, and overall quality of metal wires, making them more suitable for demanding applications in industries like automotive and construction.

3. What types of metals can be processed with an inverted wire drawing machine?

Inverted wire drawing machines can process various metals, including steel, copper, aluminum, and other alloys, depending on the machine's specifications.

4. How often should maintenance be performed on an inverted wire drawing machine?

Regular maintenance should be conducted according to the manufacturer's guidelines, typically every few months, or more frequently if the machine operates under heavy loads.

5. Can I customize the specifications of an inverted wire drawing machine?

Many manufacturers offer customizable options for their inverted wire drawing machines, allowing you to tailor features to meet your specific production needs.

Conclusion

Selecting the right inverted wire drawing machine is a critical decision that can significantly impact your manufacturing operations. By considering essential features such as die configuration, operational efficiency, tension control systems, and build quality, you can ensure that your investment meets the demands of your production needs. Additionally, evaluating factors like brand reputation, compatibility, and cost versus value will further guide you toward making an informed choice. With the right equipment in place, your operations can achieve the desired quality and efficiency, positioning you for success in the competitive metal processing industry.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

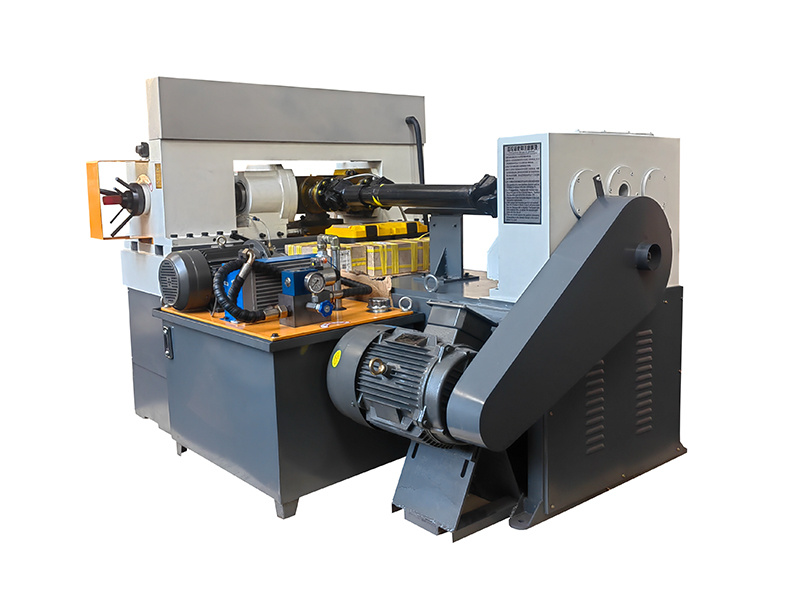

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us