The Essential Guide to Nut Slotting Machines in Post-Processing Manufacturing

Summary:

In the realm of manufacturing and processing machinery, the nut slotting machine stands out as a crucial tool in post-processing applications. Primarily utilized for creating slots in various materials, these machines are essential for enhancing the functionality and quality of finished products. By understanding the operation and benefits of nut slotting machines, manufacturers can significantly

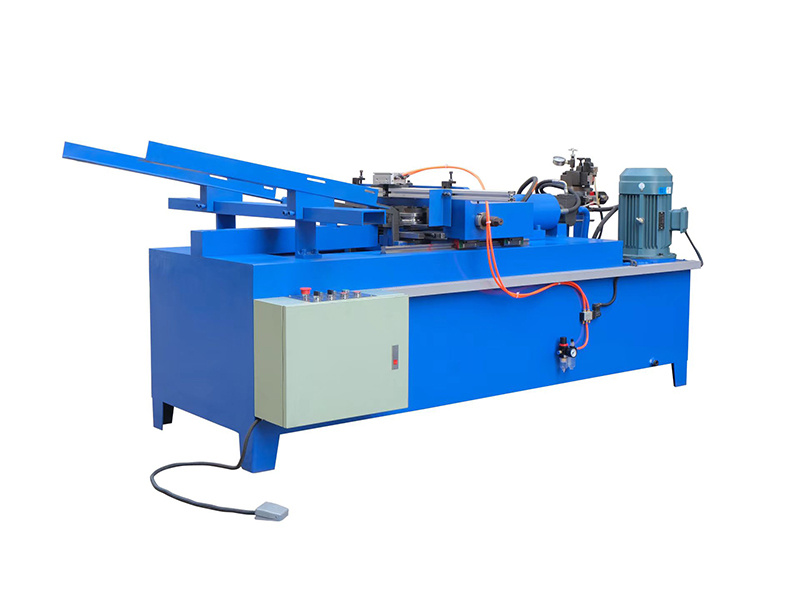

In the realm of manufacturing and processing machinery, the nut slotting machine stands out as a crucial tool in post-processing applications. Primarily utilized for creating slots in various materials, these machines are essential for enhancing the functionality and quality of finished products. By understanding the operation and benefits of nut slotting machines, manufacturers can significantly improve their production efficiency and product performance.

Nut slotting machines are engineered to create precise slots, which are often necessary for assembling components in various industries, including automotive, aerospace, and electronics. The slots allow for the secure insertion of nuts and bolts, enabling robust assembly and ensuring that components remain intact under various conditions. This precision is paramount, as even slight deviations can lead to product failures or inefficiencies in assembly.

One of the key advantages of using a nut slotting machine is its ability to improve manufacturing speed and accuracy. Automated slotting machines can perform tasks much faster than manual methods, significantly reducing production timelines. Additionally, the accuracy achieved through advanced technology minimizes the need for rework and scrap, thus saving costs and resources for manufacturers.

Moreover, nut slotting machines are designed to handle a variety of materials, including metals, plastics, and composites. This versatility makes them ideal for manufacturers producing diverse product lines. Operators can easily adjust settings to accommodate different material types and slot dimensions, ensuring that the machine meets specific production requirements.

Maintenance of nut slotting machines is also a key consideration for manufacturers. Regular upkeep not only extends the life of the equipment but also maintains the quality of the output. Simple routine checks can prevent breakdowns and ensure that the machine operates at peak efficiency, thereby avoiding costly downtimes.

In conclusion, nut slotting machines are indispensable tools in the post-processing phase of manufacturing. Their ability to produce precise slots efficiently contributes to the overall quality and integrity of assembled products. Understanding how to leverage these machines effectively can lead to improved production processes, reduced costs, and enhanced product reliability. As industries continue to evolve, the importance of nut slotting machines will only grow, making them a key investment for manufacturers aiming for excellence in their operations.

Nut slotting machines are engineered to create precise slots, which are often necessary for assembling components in various industries, including automotive, aerospace, and electronics. The slots allow for the secure insertion of nuts and bolts, enabling robust assembly and ensuring that components remain intact under various conditions. This precision is paramount, as even slight deviations can lead to product failures or inefficiencies in assembly.

One of the key advantages of using a nut slotting machine is its ability to improve manufacturing speed and accuracy. Automated slotting machines can perform tasks much faster than manual methods, significantly reducing production timelines. Additionally, the accuracy achieved through advanced technology minimizes the need for rework and scrap, thus saving costs and resources for manufacturers.

Moreover, nut slotting machines are designed to handle a variety of materials, including metals, plastics, and composites. This versatility makes them ideal for manufacturers producing diverse product lines. Operators can easily adjust settings to accommodate different material types and slot dimensions, ensuring that the machine meets specific production requirements.

Maintenance of nut slotting machines is also a key consideration for manufacturers. Regular upkeep not only extends the life of the equipment but also maintains the quality of the output. Simple routine checks can prevent breakdowns and ensure that the machine operates at peak efficiency, thereby avoiding costly downtimes.

In conclusion, nut slotting machines are indispensable tools in the post-processing phase of manufacturing. Their ability to produce precise slots efficiently contributes to the overall quality and integrity of assembled products. Understanding how to leverage these machines effectively can lead to improved production processes, reduced costs, and enhanced product reliability. As industries continue to evolve, the importance of nut slotting machines will only grow, making them a key investment for manufacturers aiming for excellence in their operations.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us