The Integration of AI in Automatic Cutting and Threading Machine Operations: Revolutionizing the Manufacturing Landscape

Summary:

The Integration of AI in Automatic Cutting and Threading Machine Operations

Manufacturing has witnessed a paradigm shift with the rise of artificial intelligence (AI), particularly in the realm of automatic cutting and threading machines. As industries strive for greater efficiency, precision, and cost-effectiveness, AI emerges as a pivotal force. This article examines how AI is revolutionizing op

The Integration of AI in Automatic Cutting and Threading Machine Operations

Manufacturing has witnessed a paradigm shift with the rise of artificial intelligence (AI), particularly in the realm of automatic cutting and threading machines. As industries strive for greater efficiency, precision, and cost-effectiveness, AI emerges as a pivotal force. This article examines how AI is revolutionizing operations in automatic cutting and threading, enhancing both productivity and quality across various sectors.

Table of Contents

1. Introduction to AI in Manufacturing

2. What is AI and How Does it Work?

3. Understanding Automatic Cutting and Threading Machines

4. Benefits of AI in Cutting and Threading Operations

- 4.1 Increased Efficiency

- 4.2 Enhanced Precision and Quality Control

- 4.3 Predictive Maintenance and Downtime Reduction

5. Real-World Applications of AI in Cutting and Threading

6. Challenges and Concerns of Implementing AI

7. The Future of AI in Manufacturing Processes

8. Conclusion

9. Frequently Asked Questions

Introduction to AI in Manufacturing

Artificial Intelligence is driving innovation across multiple industries, and manufacturing is no exception. The integration of AI technologies into cutting and threading operations allows for streamlined processes that not only enhance productivity but also significantly reduce operational costs. By leveraging AI, manufacturers can optimize their operations and stay competitive in an ever-evolving marketplace.

What is AI and How Does it Work?

Artificial Intelligence refers to the simulation of human intelligence in machines programmed to think and learn. AI technologies encompass a variety of fields, including machine learning, natural language processing, and robotics. In the context of manufacturing, AI can analyze data, identify patterns, and make real-time decisions more efficiently than human operators.

AI systems can be deployed in various capacities, such as monitoring machinery performance, predicting failures, and optimizing workflows. These systems utilize algorithms and vast datasets to continuously improve their outputs, creating a self-learning environment that enhances operational efficiency.

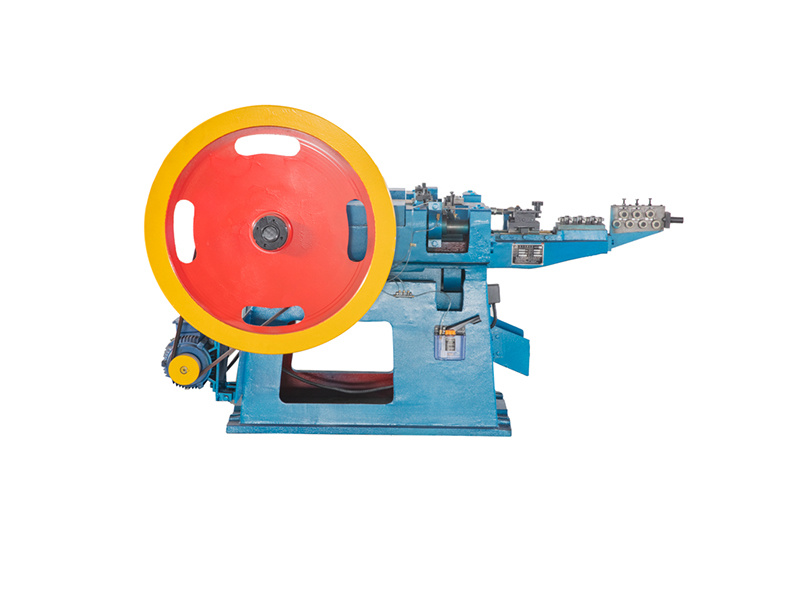

Understanding Automatic Cutting and Threading Machines

Automatic cutting and threading machines are essential tools in the manufacturing sector, particularly in the production of components requiring precision cutting and threading. These machines automate processes that were once manual, reducing labor costs and increasing throughput.

The core functions of these machines include:

- **Cutting**: Accurately dividing raw materials into desired shapes and sizes.

- **Threading**: Creating threads on various materials, enabling the assembly of components.

The evolution of these machines has led to the integration of advanced features, making them more adaptable and effective in meeting diverse manufacturing needs.

Benefits of AI in Cutting and Threading Operations

The integration of AI into automatic cutting and threading machines brings forth several advantages that can significantly impact a manufacturer’s bottom line.

4.1 Increased Efficiency

AI-powered machines optimize cutting and threading operations by automatically adjusting parameters based on real-time data analysis. This leads to reduced cycle times and minimized waste, allowing manufacturers to produce more in less time. Automation, coupled with AI insights, ensures that operations run smoothly, reducing the need for human intervention.

4.2 Enhanced Precision and Quality Control

AI systems enhance the precision of cutting and threading processes by implementing real-time quality checks. By analyzing output continuously, these systems can detect anomalies and adjust operations instantly, ensuring that every component meets the required specifications. This level of precision minimizes defects and rework, thus improving overall product quality.

4.3 Predictive Maintenance and Downtime Reduction

One of the most significant advantages of AI integration is predictive maintenance. AI can analyze machine performance data to identify potential failures before they occur. By scheduling maintenance proactively, manufacturers can minimize unexpected downtimes and extend the lifespan of their equipment, ultimately leading to cost savings.

Real-World Applications of AI in Cutting and Threading

Numerous industries are harnessing the power of AI in their cutting and threading operations. Here are some notable examples:

1. **Automotive Industry**: AI-driven cutting machines are utilized for precision parts manufacturing, enhancing production rates while maintaining high-quality standards.

2. **Aerospace Sector**: Automatic threading machines integrated with AI ensure the stringent quality requirements of aerospace components, significantly reducing the risk of failure.

3. **Electronics Manufacturing**: AI helps streamline the production of intricate electronic components, improving efficiency and reducing material waste.

These real-world applications illustrate the versatility of AI in enhancing cutting and threading operations across various sectors.

Challenges and Concerns of Implementing AI

While the benefits of integrating AI are substantial, several challenges must be addressed:

- **High Initial Investment**: Deploying AI technologies requires significant upfront costs, which can be a barrier for smaller manufacturers.

- **Skill Gap**: There exists a need for skilled personnel who can operate and maintain AI-driven machines, necessitating investment in training and education.

- **Data Security Risks**: The reliance on data raises concerns regarding cybersecurity, as sensitive information could be vulnerable to breaches.

Overcoming these challenges is crucial for manufacturers looking to reap the full benefits of AI in their operations.

The Future of AI in Manufacturing Processes

The future of AI in manufacturing, particularly in cutting and threading operations, is promising. As technology continues to evolve, we can expect more sophisticated AI systems that integrate seamlessly into production lines. This evolution will lead to:

- **Greater Automation**: The trend toward fully automated factories will intensify, with AI systems taking on more complex tasks.

- **Customization and Flexibility**: Manufacturers will increasingly leverage AI to produce customized products at scale, meeting the diverse needs of consumers.

- **Sustainability Initiatives**: AI can also play a significant role in optimizing resource use and minimizing waste, contributing to a more sustainable manufacturing landscape.

Conclusion

The integration of AI in automatic cutting and threading machine operations is not just a trend; it represents a fundamental shift in how manufacturing processes are optimized. By enhancing efficiency, precision, and predictive maintenance, AI empowers manufacturers to stay competitive in a rapidly evolving market. As we look to the future, embracing AI technologies will be essential for those seeking to thrive in the manufacturing sector.

Frequently Asked Questions

1. What types of AI technologies are used in cutting and threading machines?

AI technologies such as machine learning, computer vision, and predictive analytics are commonly used to enhance the performance of cutting and threading machines.

2. How does AI improve quality control in manufacturing?

AI systems continuously monitor production processes, enabling real-time quality checks that detect anomalies and ensure adherence to specifications.

3. Can small manufacturers benefit from AI integration?

Yes, even small manufacturers can benefit from AI integration by improving efficiency and reducing operational costs, although initial investments may be a consideration.

4. What challenges do manufacturers face when implementing AI?

Challenges include high costs, skill gaps in the workforce, and data security risks associated with AI technologies.

5. Is AI the future of manufacturing?

Yes, AI is expected to play a crucial role in the future of manufacturing, driving innovation and efficiency across various sectors.

By addressing these questions and concerns, manufacturers can make informed decisions about integrating AI into their cutting and threading operations. The path forward is not just about embracing technology but also about reimagining the future of manufacturing itself.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us